Pneumatic cinder conveying system of convertor once dry-method dedusting evaporative cooling tower under full working condition

A pneumatic conveying system, evaporative cooling technology, applied in the direction of conveyors, conveying bulk materials, manufacturing converters, etc., can solve the problems of unstable working conditions of coarse ash, high operation and maintenance costs, and high cost of vacuum suction and discharge ash tankers, and achieve reduction The effect of reducing the amount of mechanical equipment maintenance, reducing the number of mechanical equipment, and saving ash transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

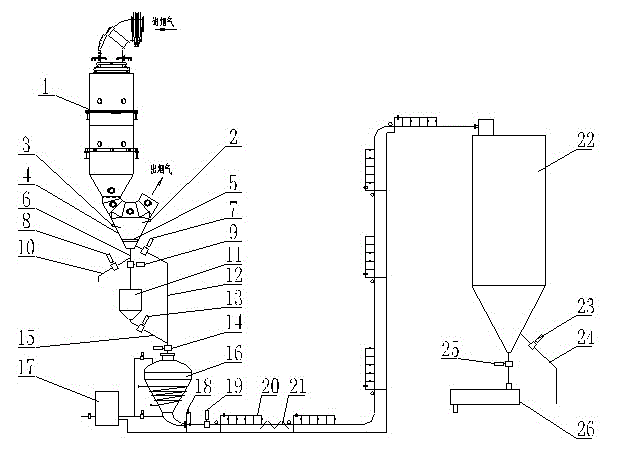

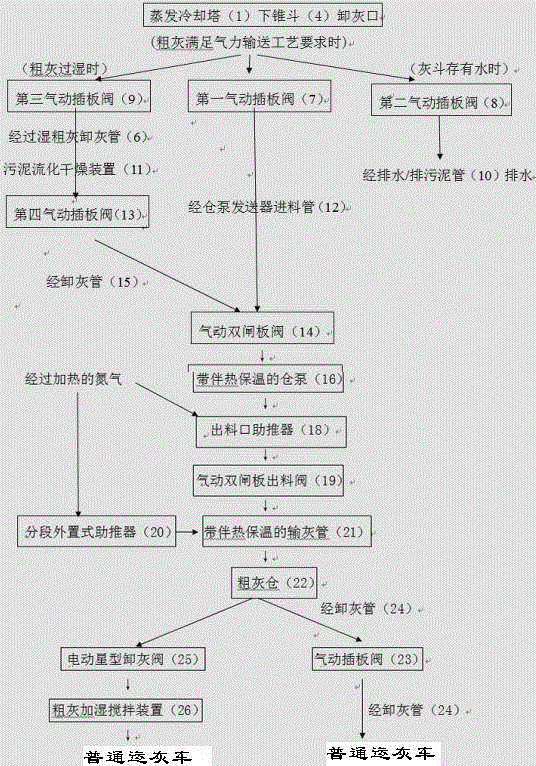

[0026] like figure 1 As shown, a dry dust removal evaporative cooling tower coarse ash pneumatic conveying system for a converter under all working conditions of the present invention includes a sequentially connected evaporative cooling tower 1, a coarse ash lower cone with heat tracing and fluidization devices Bucket 4, the first pneumatic flapper valve 7, the feed pipe of the warehouse pump transmitter 12, the pneumatic double gate valve 14, the warehouse pump transmitter with heat tracing and heat preservation device 16, the ash conveying device with nitrogen gas source heating device Air source and valve group 17, discharge port booster 18, pneumatic double gate type discharge valve 19, segmented external booster 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap