Construction method for composite pile

A construction method and technology of composite piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of difficult construction of prefabricated piles, high bearing capacity of composite piles, pile body not in place and pile length, etc. The effect of soil influence, improving the bearing capacity of foundation piles, and preventing soil collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

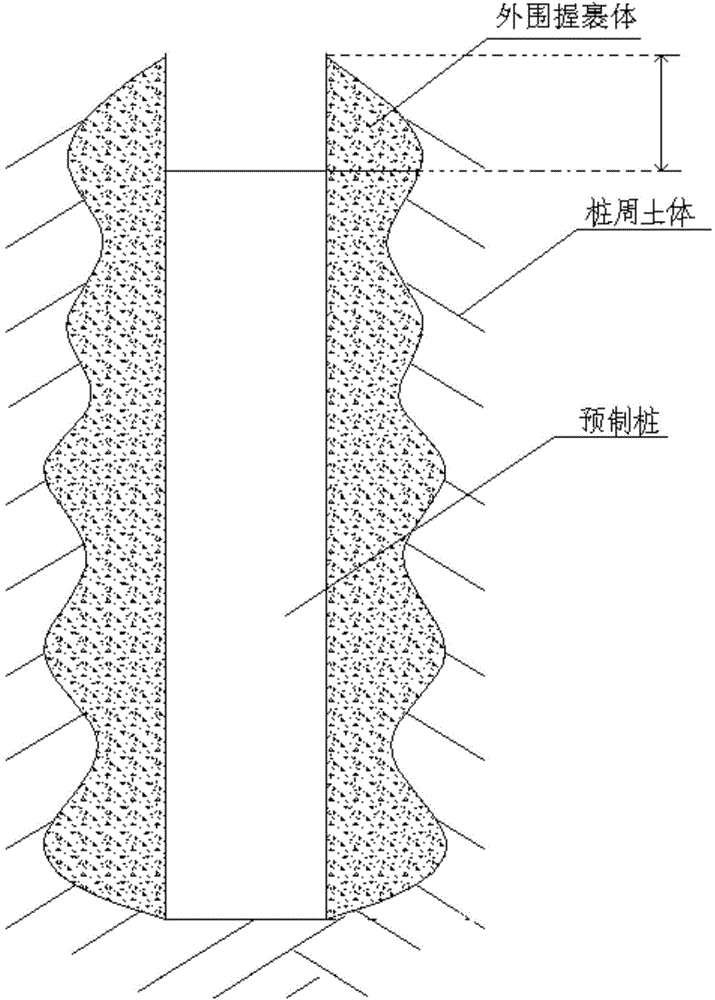

[0018] structured as figure 1 As shown, the construction method of a kind of composite pile that present embodiment provides, comprises the steps:

[0019] On the predetermined pile position, use a drilling rig to drill a hole to a set depth and press the material to be filled into the drill hole. In actual operation, the long spiral drilling and filling process is used to complete the pressure filling of the material. The specific operation is as follows: After the drilling is completed, pump the holding material into the drilling while lifting the drill pipe;

[0020] The holding material is composed of one or more of cement, cement soil, cement mortar, fine stone concrete and cement fly ash mixture that meets the pumping requirements, and the holding material is in liquid state, and the pressure filling amount of the holding material is 40%-60% of the drilling volume;

[0021] The construction of the composite pile is completed by inserting the prefabricated pile into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com