Double-hollow double-silver Low-E aluminium alloy broken-bridge heat-preservation thermal-insulation window structure

A thermal insulation, double hollow technology, applied in parallel glass structures, windows/doors, building components, etc., can solve the problem of waste of energy, unsatisfactory sound insulation effect, poor thermal insulation effect of single or double glazing, etc. problems, to achieve the effect of reducing energy consumption and improving the quality of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

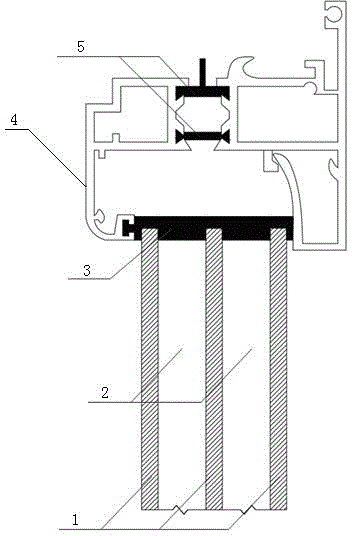

[0013] Such as figure 1 A double-hollow double-silver Low-E aluminum alloy broken bridge thermal insulation window structure shown includes three layers of double-silver Low-E glass 1 and a double hollow structure formed by the three-layer double-silver Low-E glass 1 2. The end of the three-layer double-silver Low-E glass 1 is connected to the aluminum alloy profile window frame 4 through the sealing strip 3, and the aluminum alloy profile window frame 4 is provided with a broken bridge structure inside the broken bridge structure. There is a heat insulation strip 5; the aluminum alloy profile window frame 4 is also connected with a steel sub-frame through stainless steel screws, and the steel sub-frame is fixedly connected with the wall through a steel connecting piece.

[0014] As a further optimization of the above structure, the thickness of the double-silver Low-E glass is 5mm, and the number of double-silver film layers is 9. The thickness of the hollow structure formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com