Engine oil pump and engine lubrication system thereof

An engine and oil pump technology, applied in the direction of engine lubrication, engine components, machines/engines, etc., can solve the problems of large inclination angle between the engine and the oil pan, affecting the normal lubrication of the engine, and insufficient oil absorption by the oil pump, so as to reduce the weight. , The effect of reducing its own height and increasing the ground clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

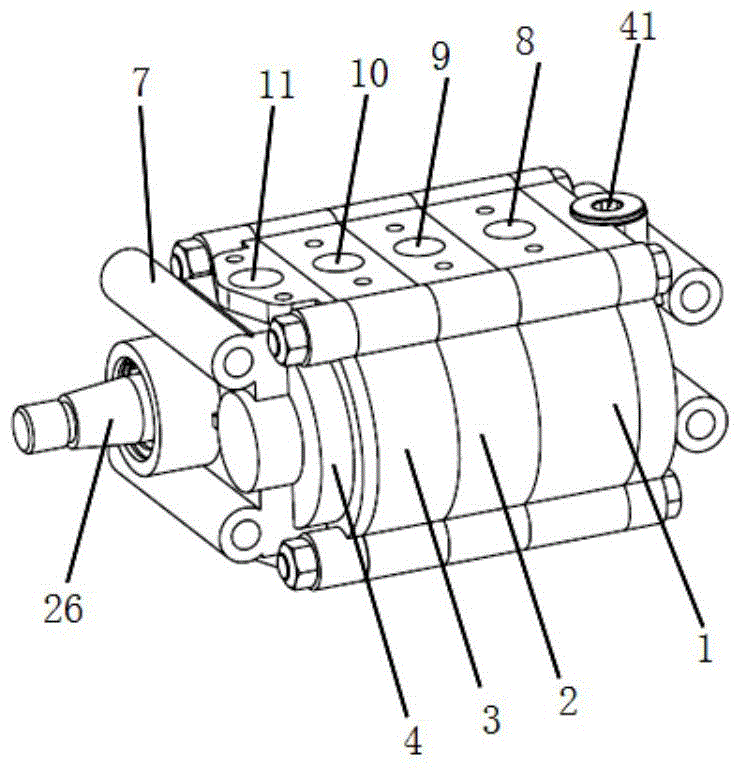

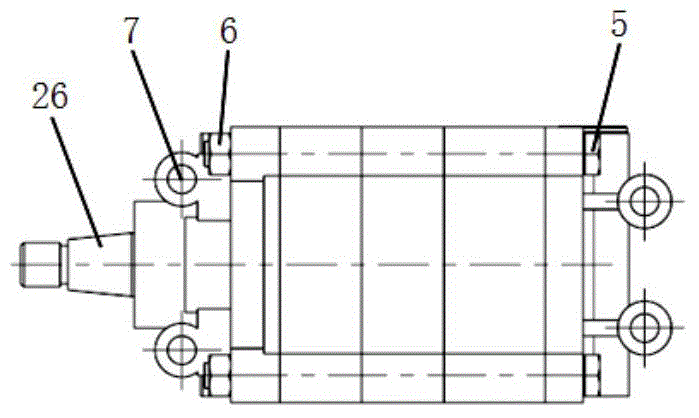

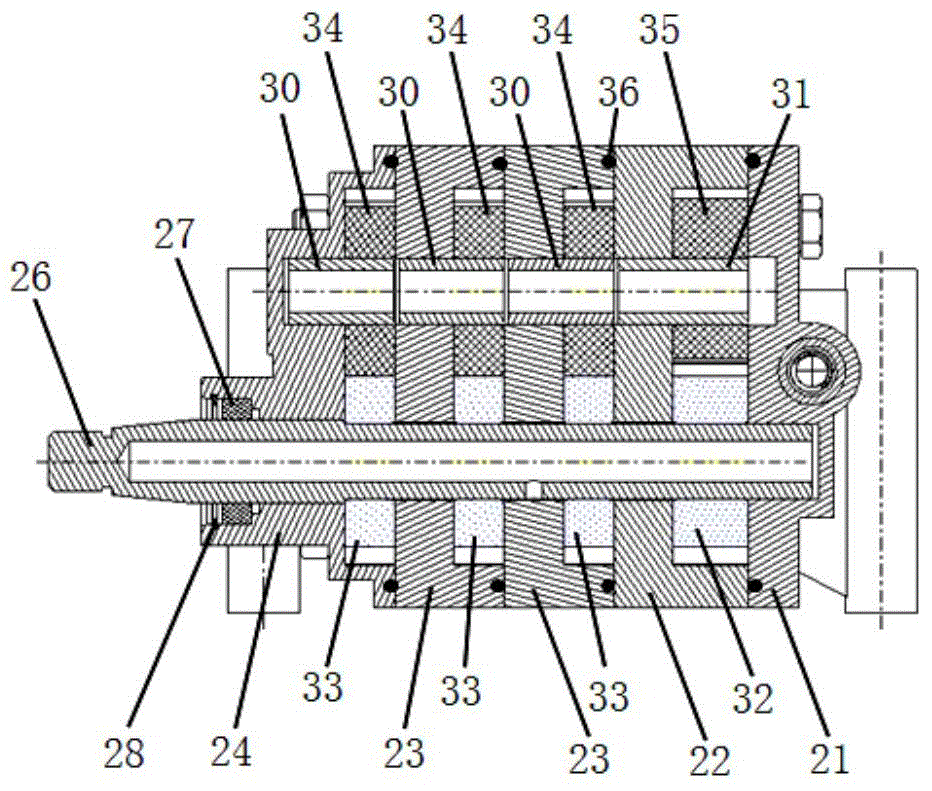

[0027] Such as Figure 1 to Figure 5 As shown, the engine oil pump includes a main pump 1 and three auxiliary pumps, and the three auxiliary pumps are respectively auxiliary pump I2, auxiliary pump II3, and auxiliary pump III4. Among them, the main pump 1 and the three auxiliary pumps use Segmented side-by-side structure, the main pump casing 22 and the auxiliary pump casing 23 pass through the fixing holes on the respective casings through four bolts 5, and are locked and fixed together side by side with four corresponding nuts 6. The auxiliary pumps can be assembled into serialized products by increasing or decreasing the number of auxiliary pumps according to the design and layout requirements of the engine.

[0028] The main pump 1 and three auxiliary pumps share a drive shaft 26, the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com