Two-stage sliding valve type electro-hydraulic servo valve directly driven by limited angle torque motor

An electro-hydraulic servo valve, limited rotation angle technology, applied in the direction of servo meter circuit, servo motor assembly, fluid pressure actuating device, etc. Large amplification factor and other problems, to achieve the effect of widening the working frequency range, improving the response speed, and large output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

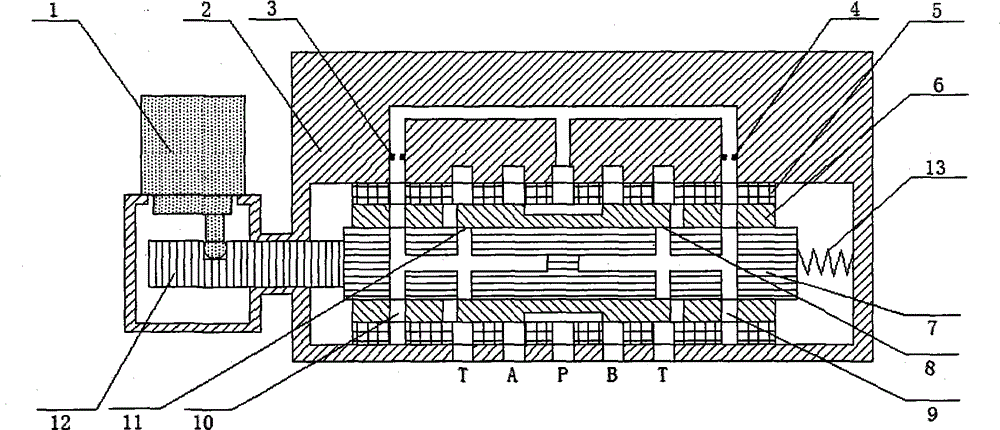

[0009] figure 1 Schematic diagram of the overall structure of the two-stage spool-type electro-hydraulic servo valve directly driven by a limited-angle torque motor, as shown in figure 1 shown. It mainly includes limited rotation angle torque motor (1), valve body (2), left fixed orifice (3), right fixed orifice (4), valve sleeve (5), main valve core (6), pilot stage valve Core (7), right throttle window (8), right control cavity (9), left control cavity (10), left throttle window (11), transmission shaft (12), return spring (13). The specific working principle is as follows: when the limited-angle torque motor (1) is stationary, the transmission shaft (12) is stationary, and the pilot stage spool is in the neutral position at this time, at this time, the pressure oil passes through the left fixed orifice (3), the left joint The pressure of the flow window (11) in the left control chamber is equal to the pressure of the pressure oil in the right control chamber through the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com