Coreless optical fiber-based tilt angle sensor capable of discriminating direction

An inclination sensor and coreless optical fiber technology, which is applied in the directions of instruments, inclination measurement, measurement devices, etc., can solve the problems of inability to judge the inclination direction and dependence of the inclination optical fiber sensor, etc., and achieve the effect of good application prospect, low cost and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

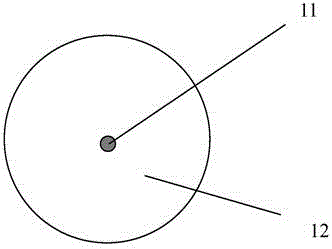

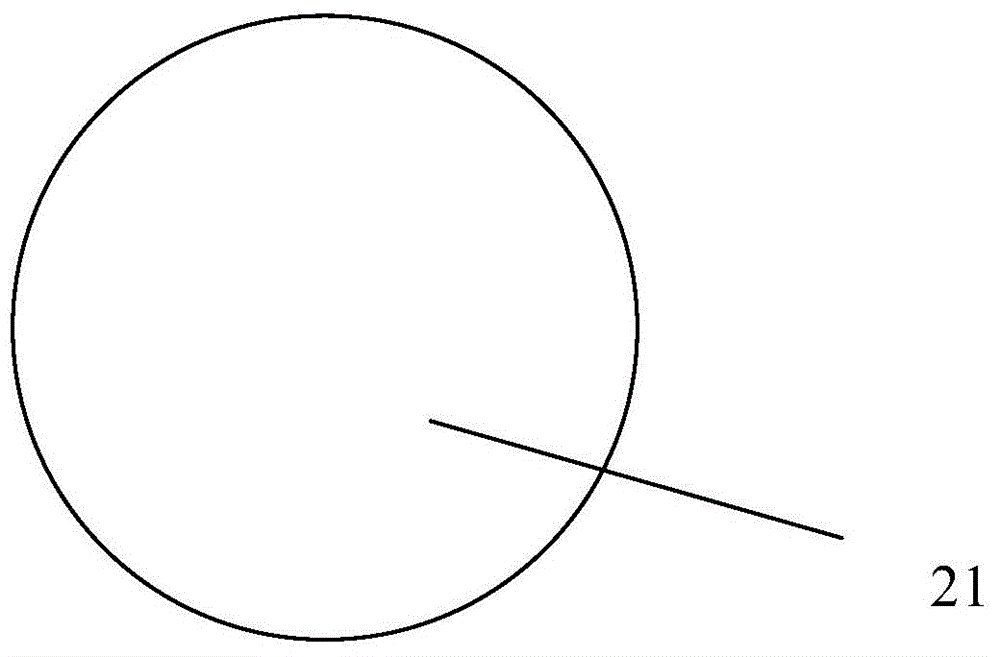

[0017] figure 1 It is a schematic diagram of a cross-section of a common single-mode optical fiber. In the center of the cladding 12, there is a core 11 with a refractive index slightly higher than that of the cladding. figure 2 It is a schematic diagram of the cross-section of the coreless fiber used in the present invention. The coreless optical fiber 21 is a type of optical fiber with a minimal structure, without a core inside, and it is actually a homogeneous light-guiding fiber. Commercially available coreless fibers are also typically coated with a polymer coating over the coreless fiber. After the coating is stripped, the coreless optical fiber uses a medium with a lower refractive index as the cladding layer to form an optical waveguide.

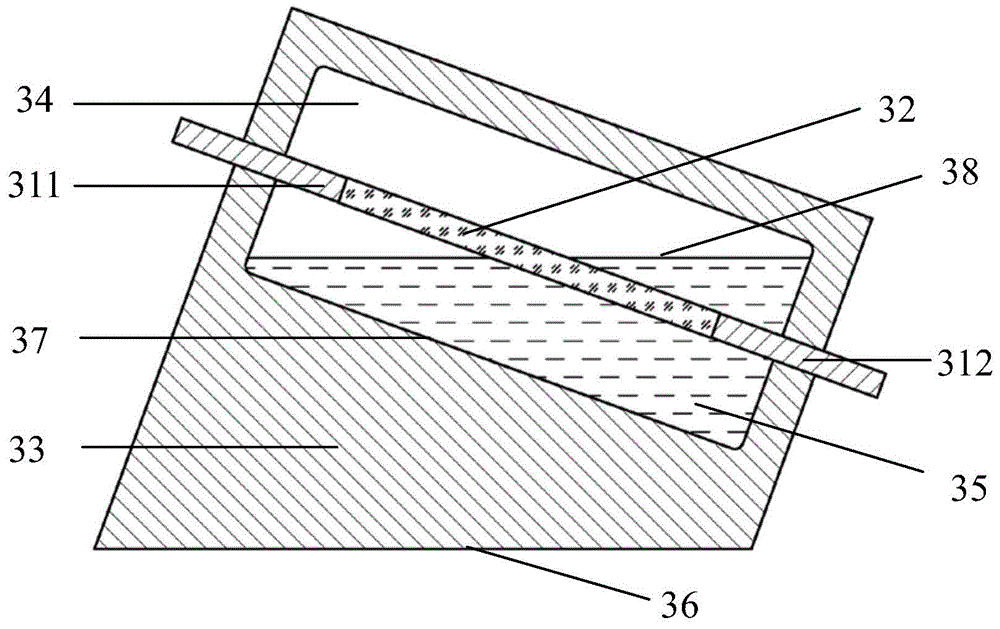

[0018] image 3 It is an application example of the present invention. A single-mode fiber 311 and another single-mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com