Test setup suitable for uniaxial tensile testing of viscoelastic materials

A uniaxial tensile and test device technology, applied in the field of material mechanics research, can solve problems such as measurement result error, and achieve the effects of neutrality, simple processing technology and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

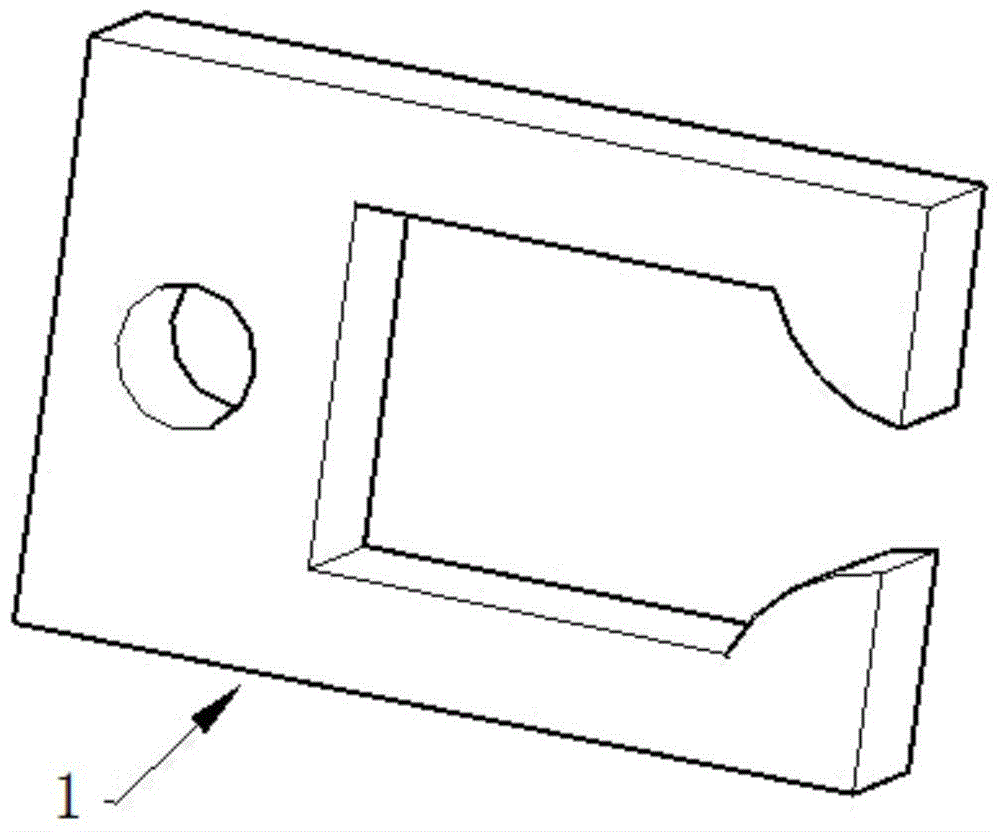

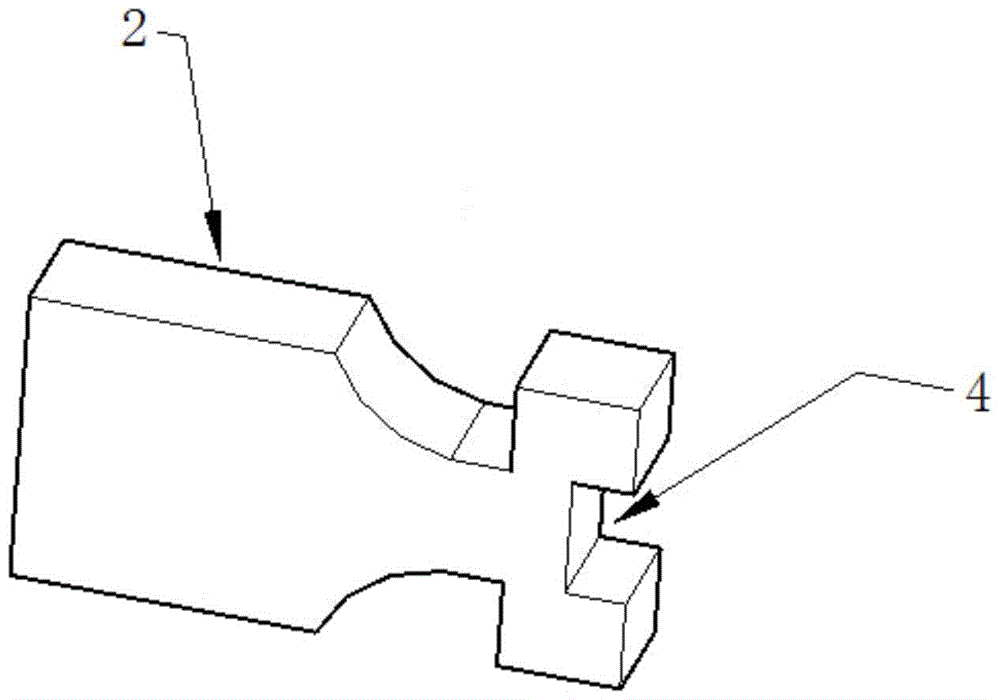

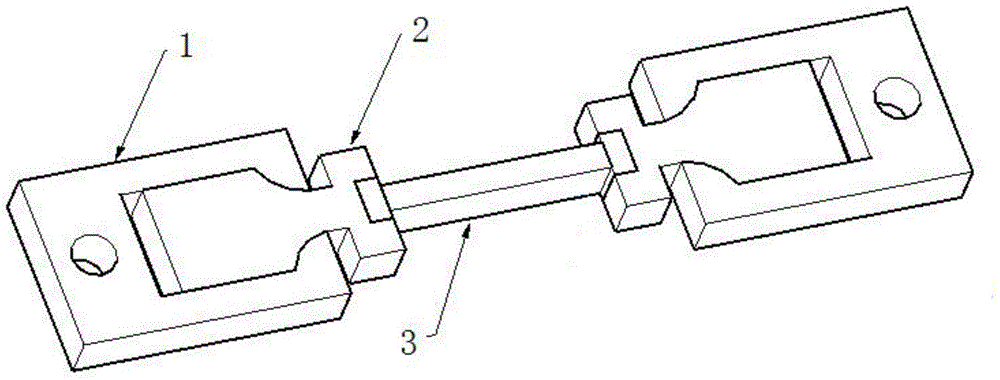

[0017] combine Figure 1 ~ Figure 3 :

[0018] The present invention is a test device suitable for uniaxial tensile tests of viscoelastic materials, comprising a dumbbell-shaped fixture 1, a connecting device 2 and a test piece 3; one end of the dumbbell-shaped fixture 1 is a connecting hole of a testing machine, and the other end is a dumbbell-shaped Clamping groove, one end of the connection device 2 matches the shape of the dumbbell-shaped clamping groove, and is embedded in the dumbbell-shaped clamping groove, the other end of the connecting device 2 has a specimen connection groove 4, and the two ends of the specimen 3 are glued by epoxy resin. It is fixedly connected in the connecting groove 4 of the test piece, and the connecting device 2 and the dumbbell-shaped clamp 1 at both ends are arranged symmetrically at both ends of the test piece 3 .

[0019] The distance between the bottom of the test piece connection groove 4 and the end face of the dumbbell-shaped fixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com