Mounting method and device with acoustic emission sensor recycling capacity

A technology of acoustic emission sensor and installation method, which is applied in the direction of material analysis using acoustic wave emission technology, measuring devices, and material analysis using sound waves/ultrasonic waves/infrasonic waves, etc., which can solve the problems of expensive sensors, waste of resources, and inability to recycle sensors, etc. problems, achieve the effect of convenient and quick installation, reduce economic costs, and improve the accuracy of signal monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

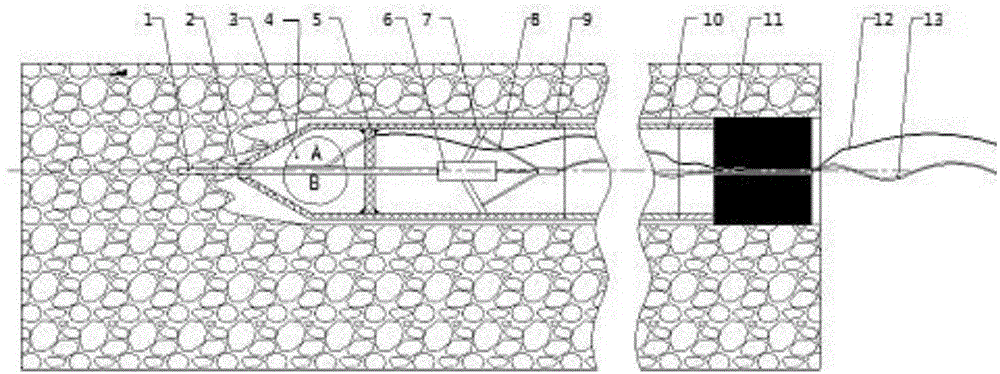

[0022] The present invention will be further described below in conjunction with accompanying drawing and embodiment: figure 1 It is a schematic diagram of the principle of the present invention. Such as figure 1 As shown, the waveguide rod 1, the drilling hole 2, the sealing liquid bag 3, the guide hole 4, the baffle 5, the acoustic emission sensor 6, the fixing claw 7, the recovery arm 8, the casing 9, the delivery pipe 10, and the sealing rubber ring 11 , sealing solution bag pull wire 12, signal wire 13.

[0023] In this embodiment, it includes a waveguide 1, a recovery device, a sealing solution bag, and a sealing solution bag pull wire 12, and the recovery device includes a fixing claw 7, a recovery arm 8, a housing 9 and a baffle 5; the baffle 5 is sealed and fixed on the In the shell 9, the inner cavity of the shell 9 is divided into a front cavity and a rear cavity, the sealing liquid bag 3 is placed in the front cavity, the acoustic emission sensor is installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com