Solar light condensation piece structure

A technology of solar concentrating and sheet structure, applied in the direction of condensing mirror, optics, optical components, etc., can solve the problems of unstable performance, heavy weight and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

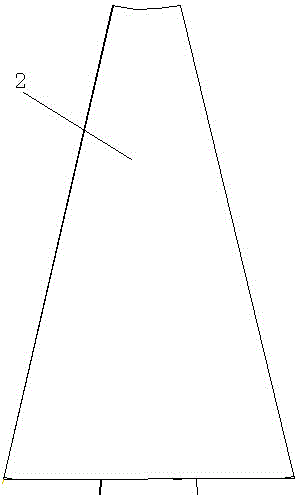

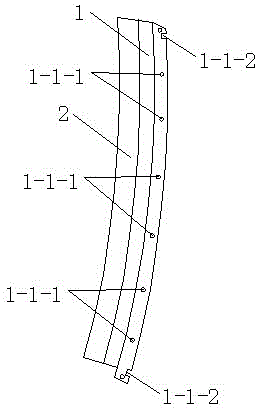

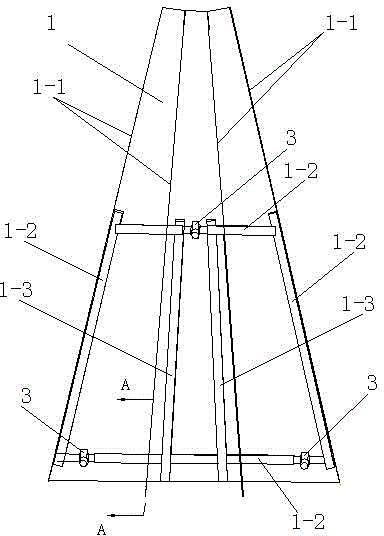

[0022] see Figure 1~8 As shown, a solar concentrating sheet structure includes a fan-shaped curved surface structure back support plate 1 and a sunlight reflection plate 2, and the sunlight reflection plate 2 is bonded to the surface of the back support plate 1, and also includes four connecting rods 1-2 and three A mounting bolt 3, four arc-shaped back ribs 1-1 are fixedly connected on the back side of the back support plate 1, and the four arc-shaped back ribs 1-1 are connected by four connecting rods 1-2, and three mounting bolts 3 are fixed Connected or hinged on the connecting rod 1-2, each arc-shaped back rib 1-1 is provided with more than two process holes 1-1-1, and the corresponding process holes 1-1-1 are located on the arc-shaped back rib 1-1 The equal radii of the sectors formed. These process holes 1-1-1 can facilitate the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com