Technology simulation testing device for horizontal well

A technology of process simulation and test equipment, which is applied in the direction of borehole/well components, measurement, earthwork drilling and production, etc., can solve the problems that the performance of horizontal well process measures cannot be fully and truly obtained, and the lack of simulating horizontal wells can improve the construction efficiency. Safety and reservoir protection effect, promotion of process technology level, promotion of improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

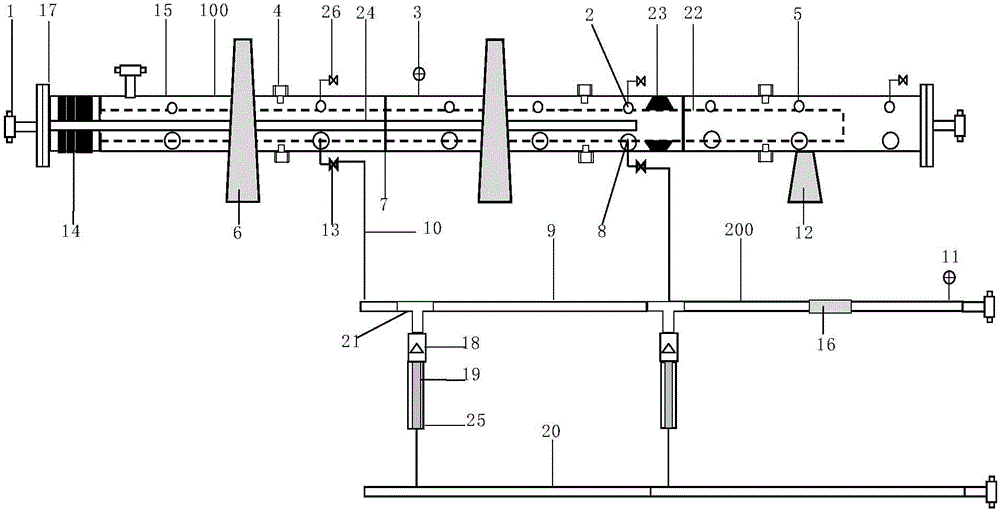

[0024] Example 1: Simulation test of horizontal well annulus chemical isolation process. This test includes steps such as device assembly, chemical agent preparation, simulated injection, test result detection and evaluation, etc.

[0025] 1. Device assembly

[0026] First, according to the test plan, assemble the test pipe string 100 and the pipe assembly 200 (the core pipe 25 and the artificial core 19 are not installed on the pipe assembly 200);

[0027] Then by adjusting the height of the lifting bracket 6, the angle of the test string 100 is consistent with the real well deviation, and the test string 100 is fixed;

[0028] Install gates on the union joints 1 at both ends of the casing 15 and close the gates, and simultaneously close all valves of the test string 100, and tighten each plug;

[0029] The cement truck pipeline is connected to the front end of the test pipe string 100, and the pressure seal test is carried out on the test pipe string 100 (compression pressu...

Embodiment 2

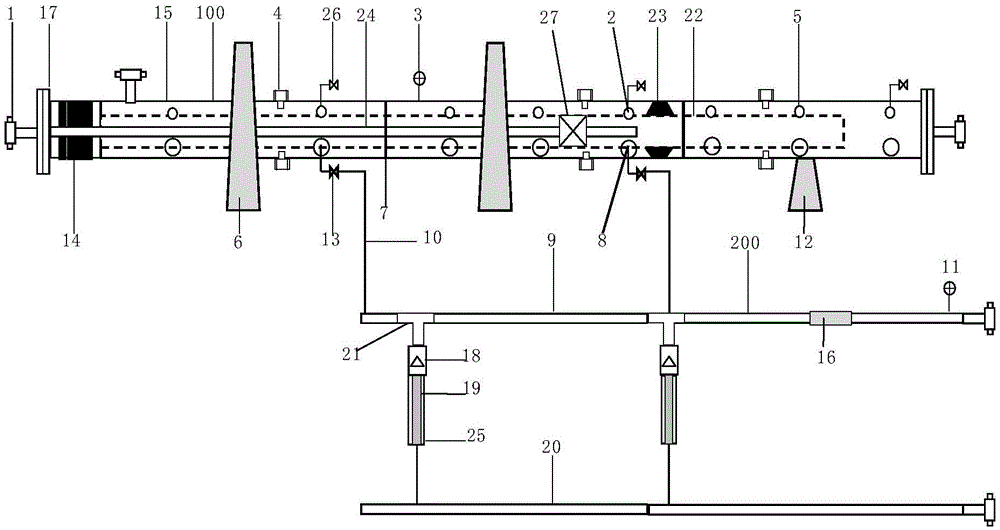

[0038] Embodiment 2: Simulation experiment of horizontal well segmented water shutoff technology (see attached figure 2 ), this test included steps such as device assembly, artificial core filling and preparation, annulus chemical sealing, segmented sealing, and simulated mining.

[0039] 1. Device assembly

[0040] First, according to the test plan, assemble the test string 100 and assemble the pipes into 200; install the packer 27 in the annulus of the test tubing 24 and the screen 22 of the test string 100;

[0041]Then by adjusting the height of the lifting bracket 6, the angle of the test string 100 is consistent with the real well deviation, and the test string 100 is fixed;

[0042] Install gates on the union joints 1 at both ends of the casing 15 and close the gates, and simultaneously close all valves of the test string 100, and tighten each plug;

[0043] The cement truck pipeline is connected to the front end of the test pipe string 100, and the pressure seal tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com