Exhaust treatment system restored by selective catalytic and exhaust treatment method restored by selective catalytic

An exhaust treatment and selective technology, applied in exhaust treatment, electronic control of exhaust treatment devices, exhaust devices, etc., can solve problems such as high risk and long cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

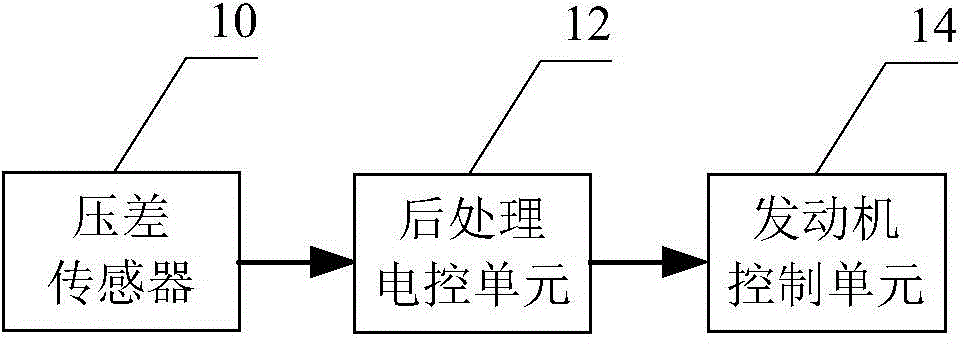

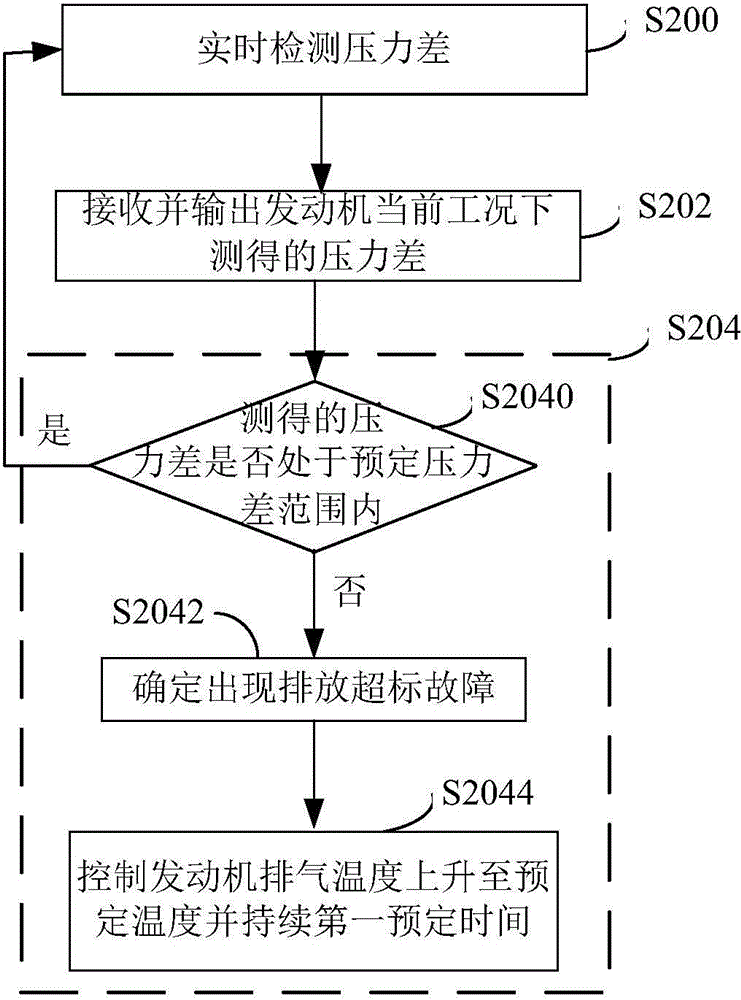

[0032] According to an embodiment of the present invention, the engine control unit determines that the emission exceeds the standard when the pressure difference measured under the current working condition of the engine is not within the pre-stored predetermined pressure difference range corresponding to the current working condition Fault.

[0033] According to another embodiment of the present invention, the post-processing electronic control unit 12 is also used to receive and output multiple pressure differences measured under multiple working conditions of the engine; the engine control unit 14 is also used to When the pressure difference measured under the current working condition of the engine is not within the predetermined pressure difference range corresponding to the pre-stored current working condition, it is judged whether the multiple pressure differences are corresponding to their respective working conditions stored in advance If any pressure difference amon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com