External packing material used for lithium ion battery

A lithium-ion battery and outer packaging technology, applied in the direction of battery box/cover material, battery box/jacket, packaging, etc., to achieve the effect of excellent printing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

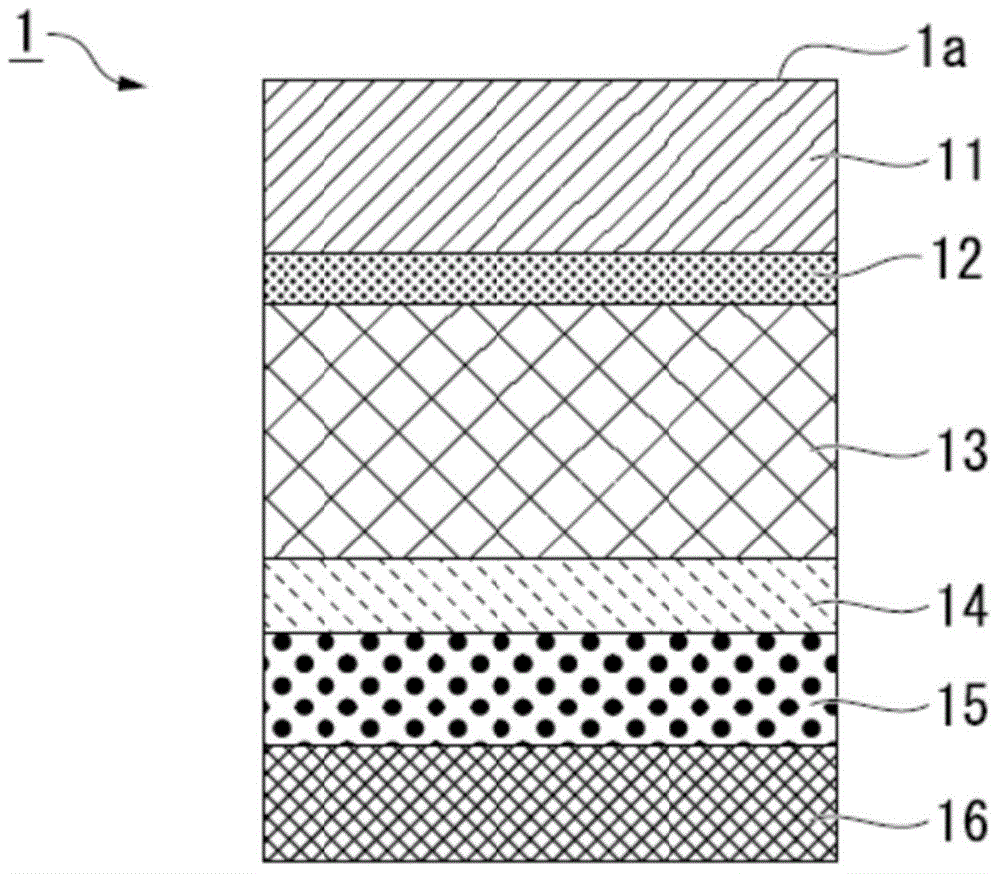

[0053] figure 1 It is a schematic sectional view showing the outer packaging material 1 according to the first embodiment of the present invention.

[0054] The outer packaging material 1 is composed of a laminated body formed by sequentially laminating a first adhesive layer 12, an aluminum foil layer 13, an adhesive resin layer 15, and a sealant layer 16 on one surface of a base material layer 11, and the An anticorrosion treatment layer 14 is provided on the surface of the aluminum foil layer 13 on the side of the sealant layer 16 .

[0055] The outer cover material 1 is printed on the surface of the base material layer 11 opposite to the first adhesive layer 12 side, that is, the surface 1 a of the outer cover material 1 on the base material layer 11 side. When a droplet of the ink solvent contained in the printing ink is attached to the surface 1a, the contact angle after 5 seconds is 10° to 30°, and the time change (5 seconds) of the contact angle is 6° or less.

[005...

no. 2 approach

[0220] Next, a second embodiment of the packaging material of the present invention will be described. In addition, in the embodiment shown below, the same code|symbol is attached|subjected to the component corresponding to 1st Embodiment, and the detailed description is abbreviate|omitted.

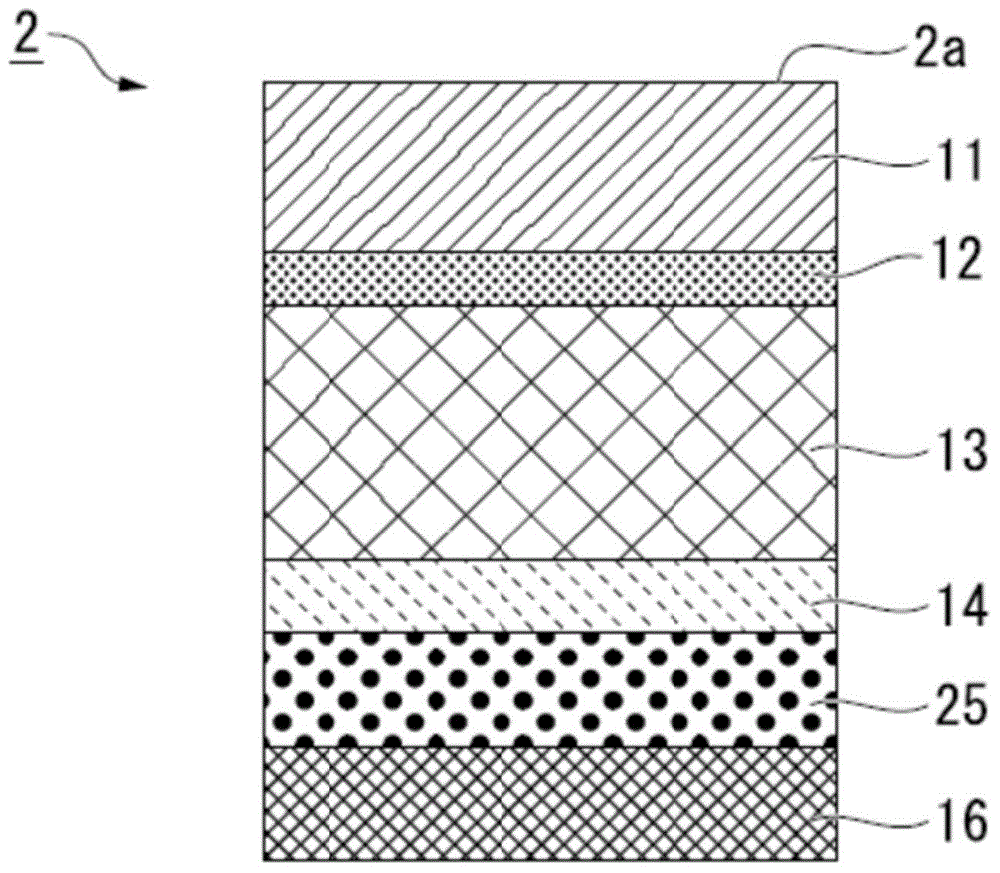

[0221] figure 2 It is a schematic sectional view showing the outer packaging material 2 according to the second embodiment of the present invention.

[0222] The outer packaging material 2 is composed of a laminated body in which a first adhesive layer 12, an aluminum foil layer 13, a second adhesive layer 25, and a sealant layer 16 are sequentially laminated on one surface of a base material layer 11, and An anticorrosion treatment layer 14 is provided on the surface of the aluminum foil layer 13 on the side of the sealant layer 16 .

[0223] The exterior material 2 is printed on the surface of the base layer 11 opposite to the first adhesive layer 12 side, that is, the surface 2 a of...

no. 3 approach

[0251] Next, a third embodiment of the packaging material of the present invention will be described.

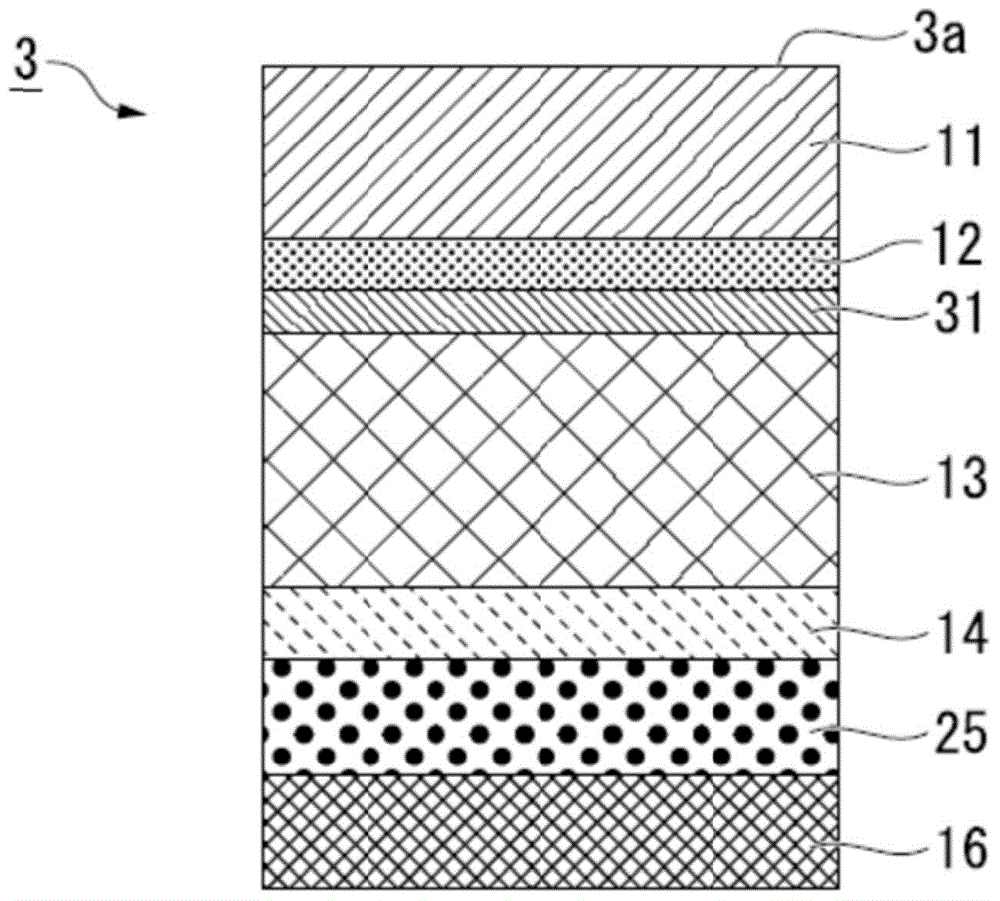

[0252] image 3 It is a schematic sectional view showing the outer packaging material 3 according to the third embodiment of the present invention.

[0253] The outer packaging material 3 is composed of a laminated body in which a first adhesive layer 12, an aluminum foil layer 13, a second adhesive layer 25, and a sealant layer 16 are sequentially laminated on one surface of a base material layer 11, and The surface treatment layer 31 is provided on the base material layer 11 side surface of the aluminum foil layer 13 , and the anticorrosion treatment layer 14 is provided on the sealant layer 16 side surface.

[0254] The outer wrapping material 3 is printed on the surface of the base material layer 11 opposite to the first adhesive layer 12 side, that is, the surface 3 a of the outer wrapping material 1 on the base material layer 11 side. When a droplet of the ink solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com