Method for applying frequency modulation technology to tobacco leaf curing equipment

A technology for curing equipment and tobacco leaves, which is applied in application, tobacco, and tobacco preparation, etc., can solve the problems of ineffective curing process, damaged aroma substances, and easily damaged electric motors, so as to protect the effective service life and improve the modulation quality. , Improve the effect of baking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

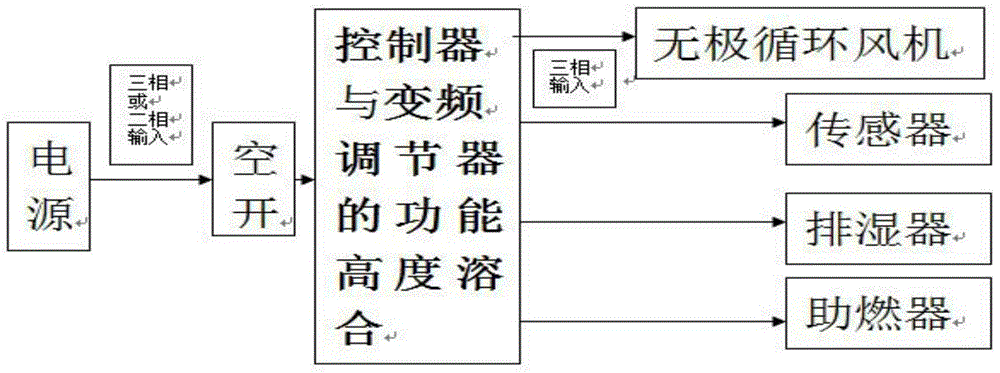

[0012] Embodiment: The present invention is illustrated below in conjunction with actual practice.

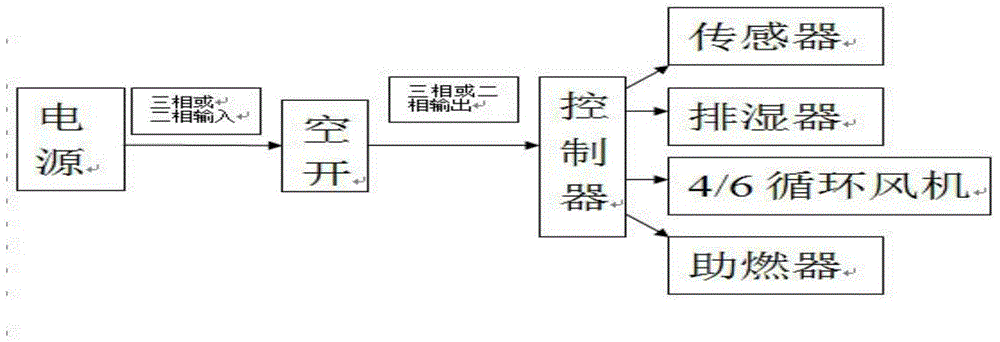

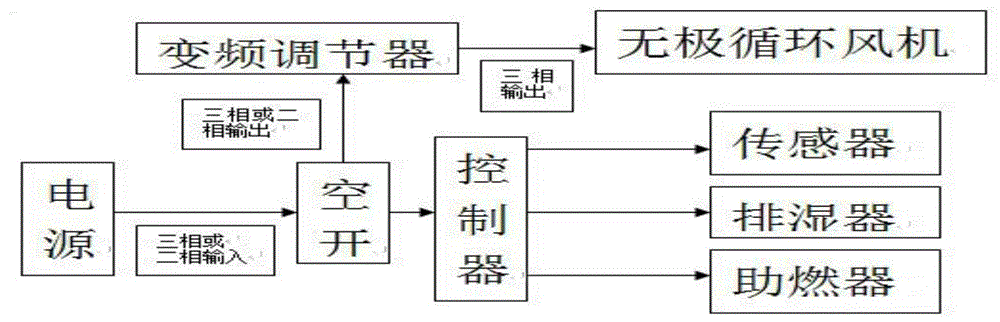

[0013] A set of tobacco leaf curing equipment such as image 3 As shown, the function of the frequency conversion regulator is integrated into the controller first, and the controller intelligently controls the stepless circulation frequency conversion fan, sensor, dehumidifier and burner. The method is to add the control of the frequency conversion adjustment function to the original controller Accessories; by using the loading function of the chip, at each time point, temperature point, and humidity point during the baking process, write the temperature and humidity sensing and command control of the sensor during baking, and write the relevant time or The temperature point controls the current frequency command, so as to realize the control of the baking requirement.

[0014] The power supply enters the air switch in three phases or two phases and then enters the controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com