Vacuum rotary dehydration device for separating ultrafine powder in catalytic cracking wet desulfurization

A technology of wet desulfurization and vacuum rotation, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of desulfurization system paralysis, large usage, and unreasonable separation of ultrafine powder, so as to prevent equipment paralysis and Large-scale maintenance, solving the waste of human resources, and avoiding the effects of direct contact and poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

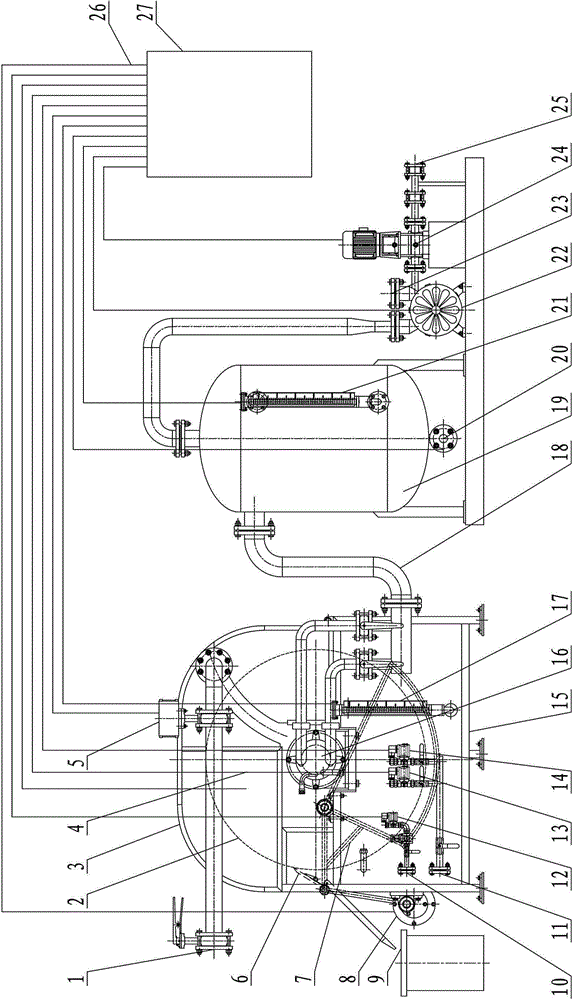

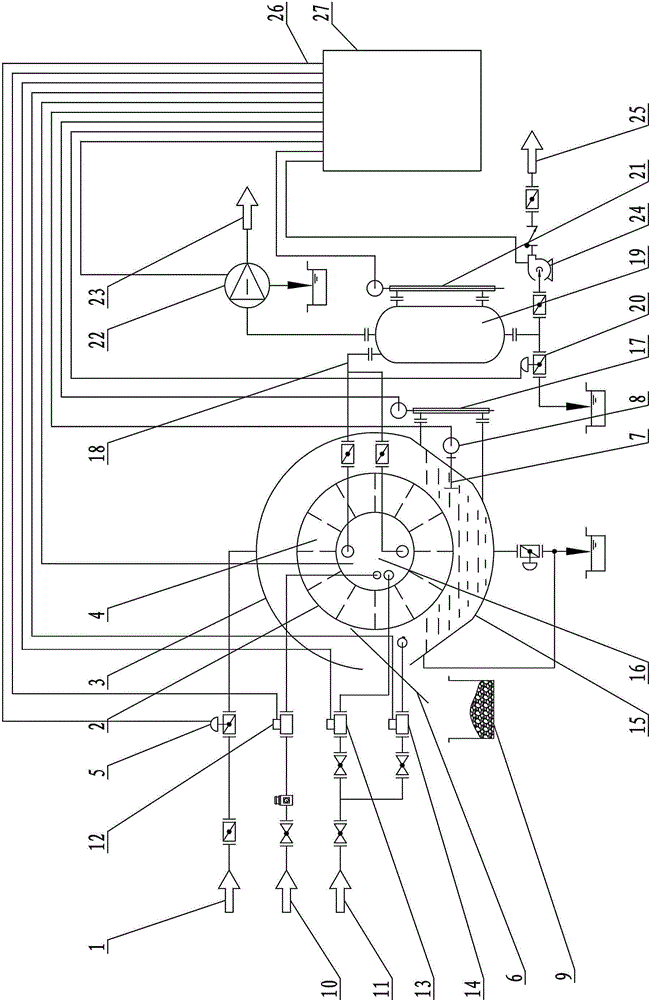

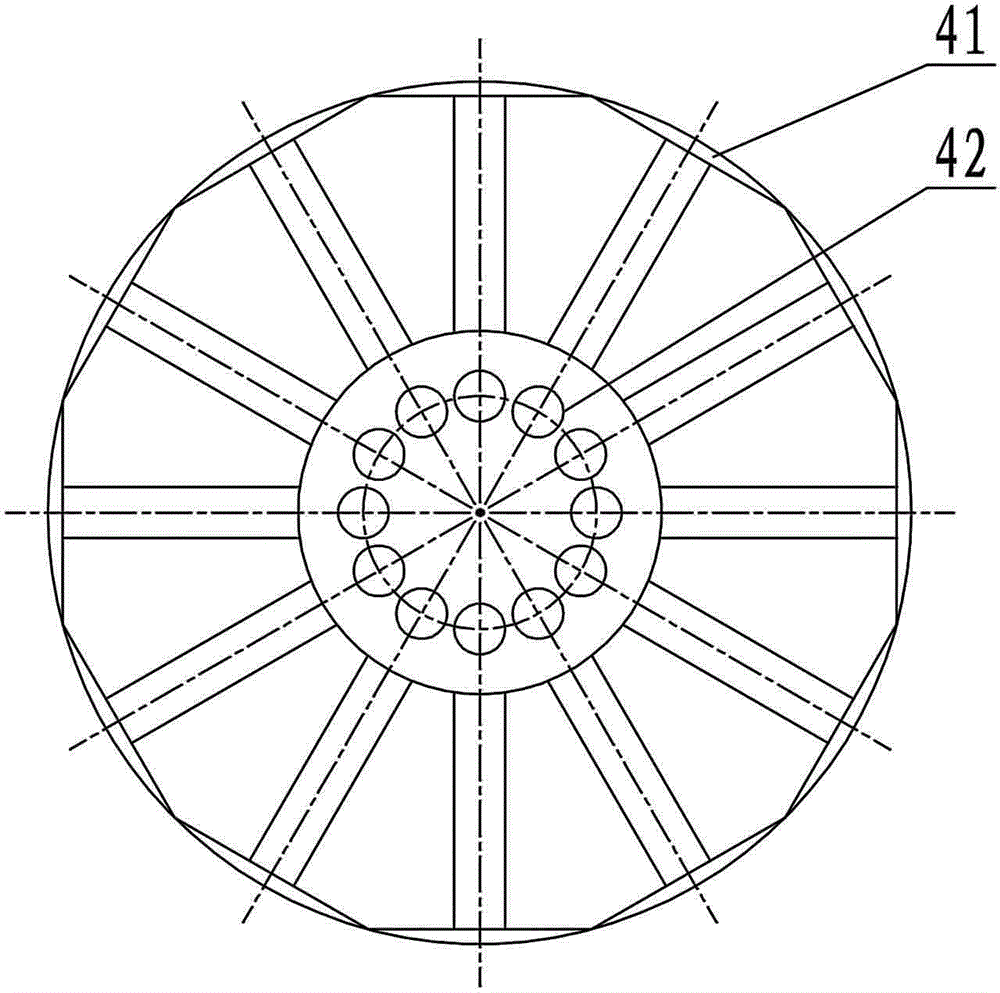

[0012] A catalytic cracking wet desulfurization ultrafine powder separation vacuum rotary dehydration device is suitable for filtration, separation and dehydration of ultrafine powder produced by a catalyst in the catalytic cracking wet desulfurization. Its specific structure is figure 1 and image 3 As shown, the liquid inlet 1 is connected with the liquid inlet valve 5, the liquid inlet valve 5 is connected with the upper casing 3, the upper casing 3 is covered on the rotary shaft 4, the rotary shaft 4 is installed on the lower casing 15, and the rotary shaft 4 is mounted on the rotary shaft 4. A stirring device 7 is installed in the gap with the lower casing 15, and the stirring device 7 is connected with the stirring driving device 8. The lower casing 15 is provided with an air inlet 10 and a flushing water inlet 11, and the flushing water inlet 11 is flushed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com