Plasma waste-gas treatment device with self-flushing function

An exhaust gas treatment device and plasma technology, applied in the field of tobacco, can solve problems such as incompatibility, and achieve the effect of ensuring the effect and the uniform reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

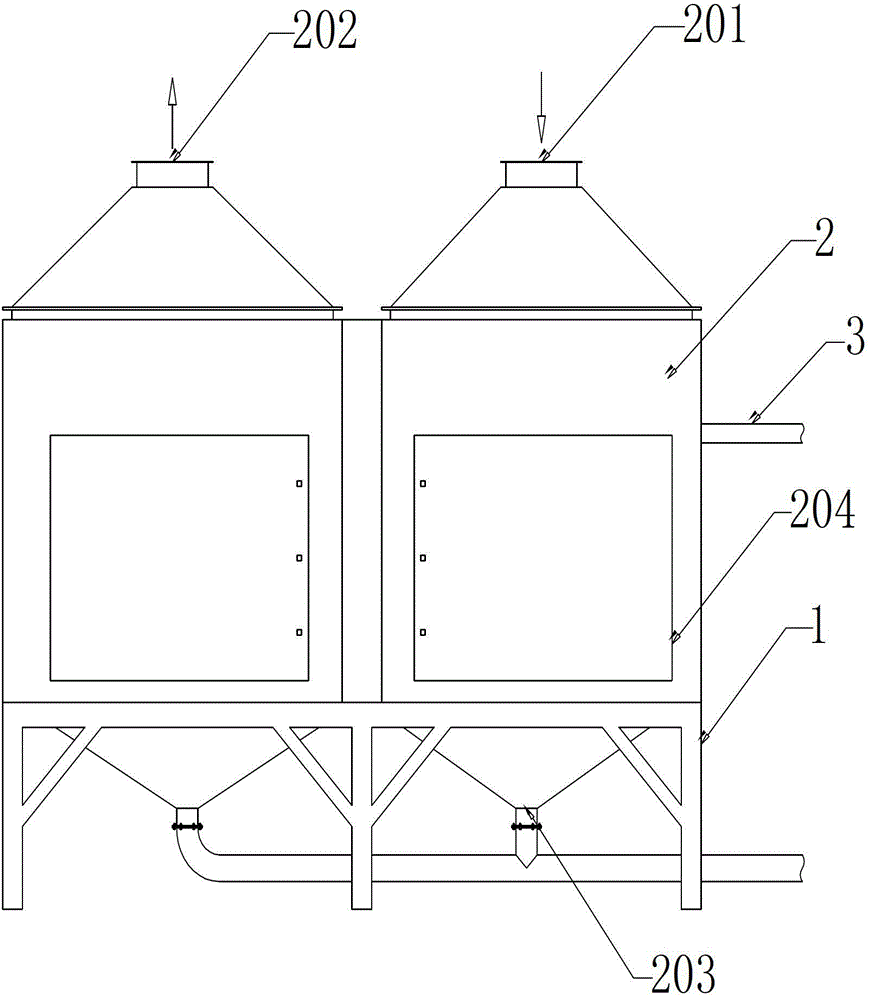

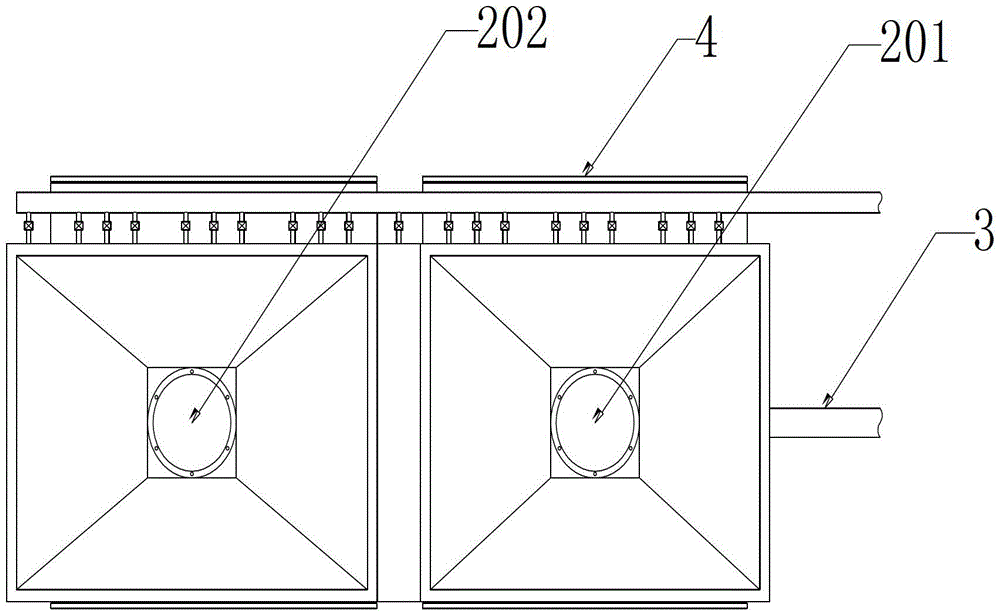

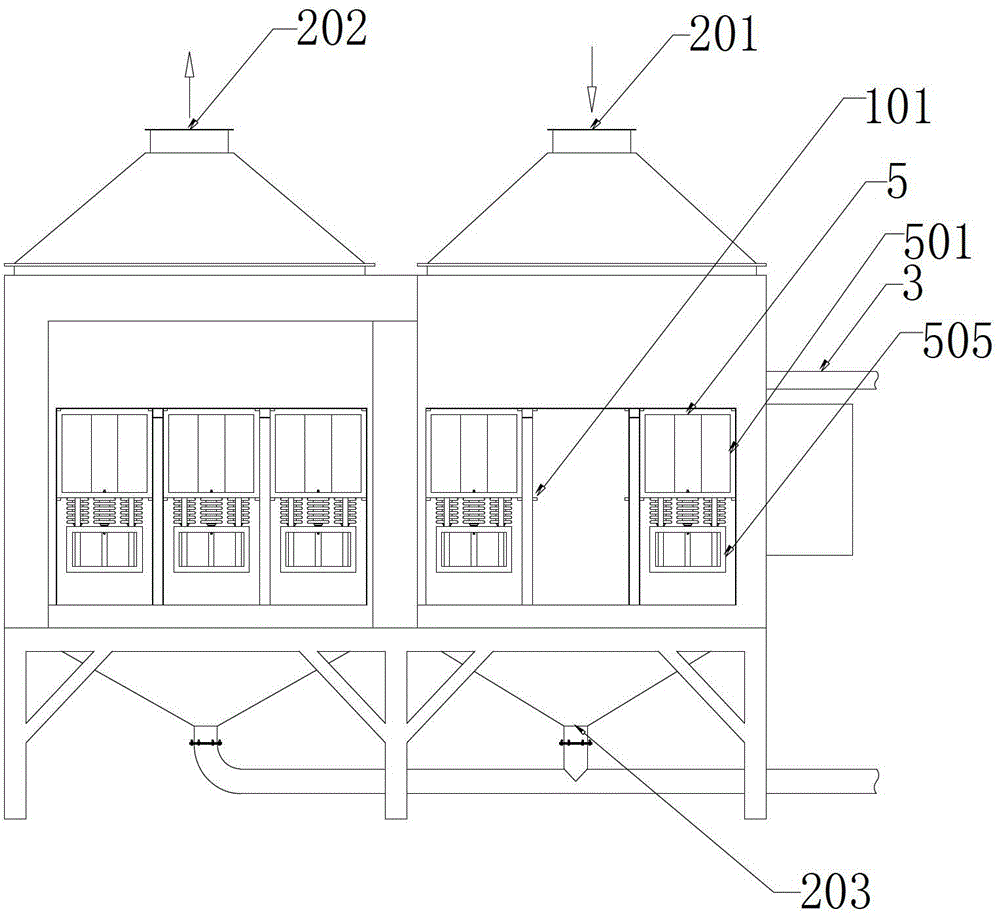

[0019] Such as figure 1 , 2 , 3, the plasma waste gas treatment device of the present invention includes a mounting frame 1, a sealing casing 2 arranged on the outer surface of the mounting frame 1, and the sealing casing 2 is provided with a waste gas inlet 201 and a waste gas outlet 202. A plasma reaction unit 5 is arranged inside the sealed casing 2, and the plasma reaction unit 5 includes a negative electrode tube 503 with a discharge tip 504 on the outer surface, and a positive electrode tube 502 concentric with the negative electrode tube 503 and sleeved outside the negative electrode tube 503. The top end of the positive tube 502 is provided with a spray device 3 for flushing the inner surface of the positive tube.

[0020] The specific exhaust gas inlet 201 is opened on the sealed casing 2 opposite to one end of the positive electrode tube 502, and the exhaust gas outlet 202 is opened on the sealed casing 2 opposite to the other end of the positive electrode tube. Dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com