Phase change heat absorption temperature control reactor

A reactor and phase change technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as difficult large-scale, over-temperature, uneven gas distribution, etc., and achieve the effect of easy over-temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

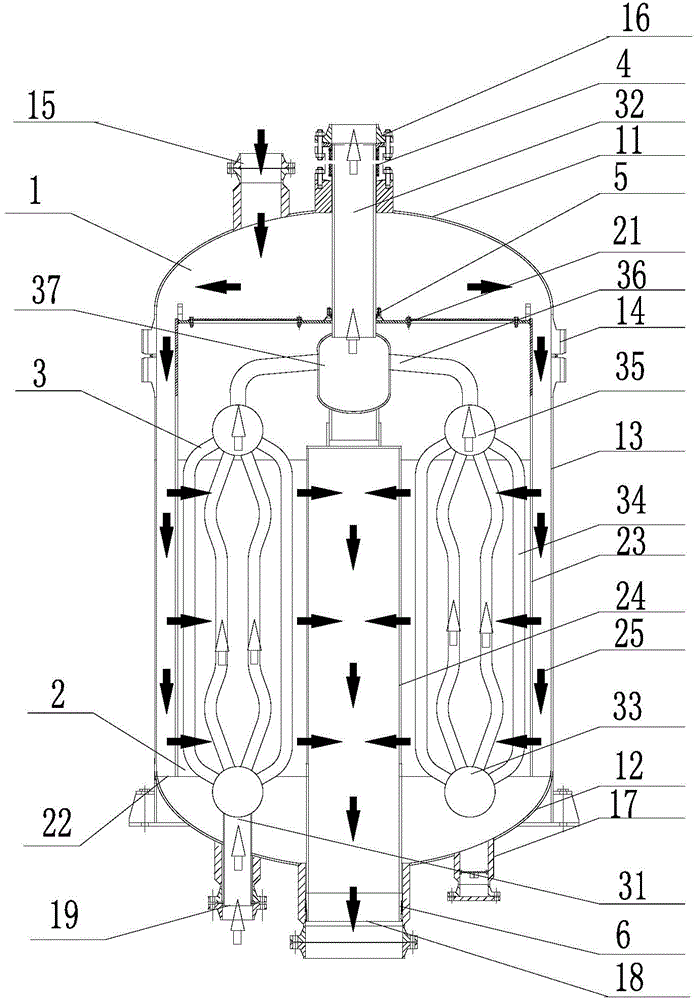

Image

Examples

Embodiment 2

[0047] This embodiment is applied to a 400,000-ton / year synthetic ammonia plant with a low water / gas ratio, and other implementations are the same as in Embodiment 1.

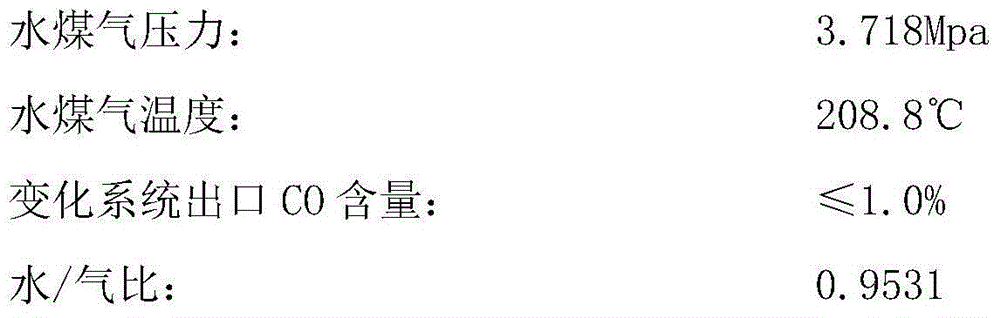

[0048] 1. Design conditions and requirements:

[0049] Change gas volume: 160273Nm 3 / h

[0050] Working pressure: 2.1MPa

[0051] Working temperature: 35~40℃

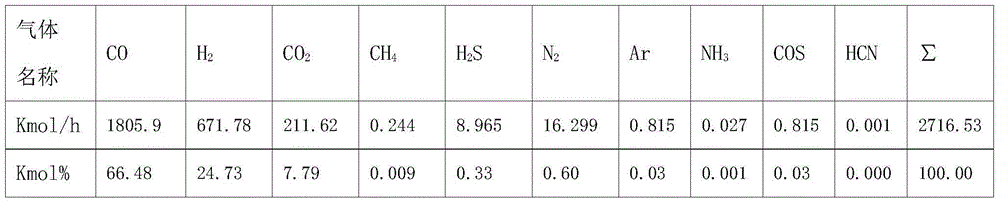

[0052] The gas composition is:

[0053] serial number name CO 2 % CO% H 2 % O 2 % N 2 % CH 4 % 1 semi water gas 7.87 29.3 46.03 0.3 15.19 1.02 2 change gas 24.00 4~8 55.40 0 12.60 0.85

[0054] 2. Compared with the adiabatic shift reactor of the traditional full low-variation process, the present invention can bring the following energy saving:

[0055] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com