Crushing and sieving integrated equipment for medicinal raw materials

A raw material crushing and sieving technology, which is applied in the direction of grain processing, etc., can solve the problems of powder dust waste, low production efficiency, inconvenient continuous production, etc., and achieve the effect of avoiding high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

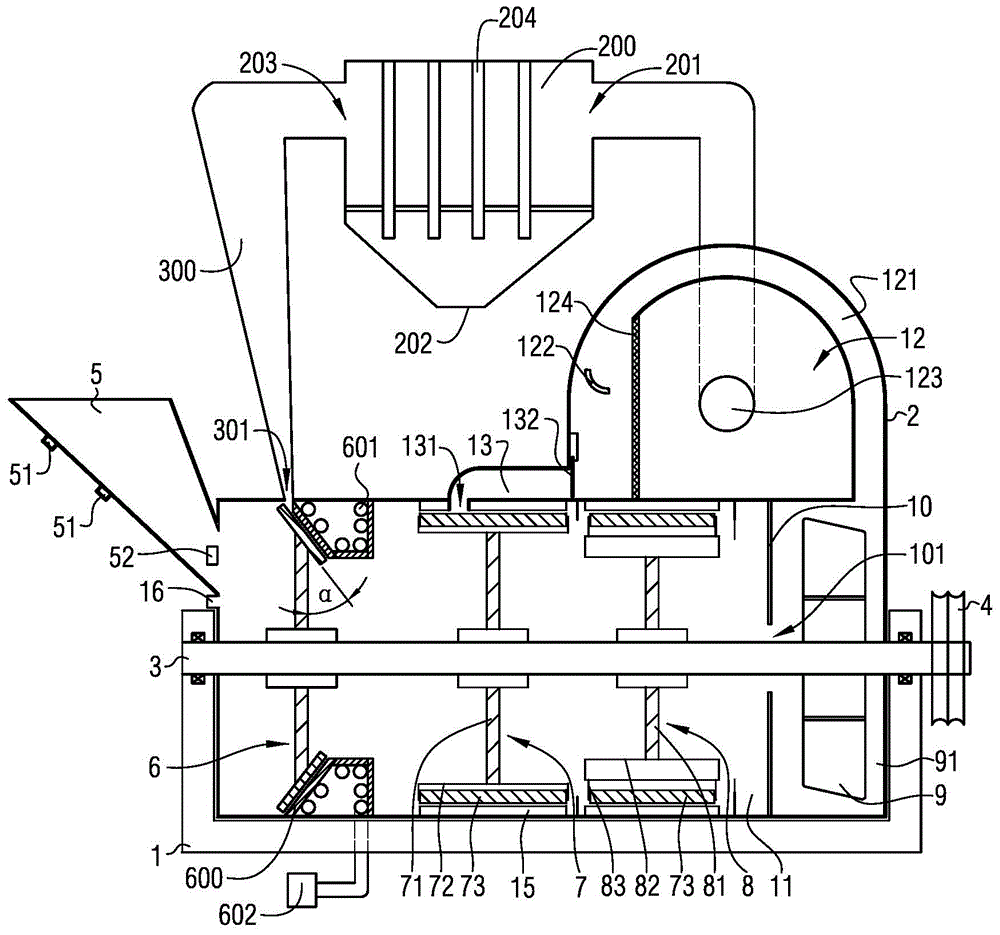

[0019] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

[0020] The structure and principle of an integrated equipment for pulverizing and screening pharmaceutical raw materials according to the present invention will be described in detail below with reference to the accompanying drawings.

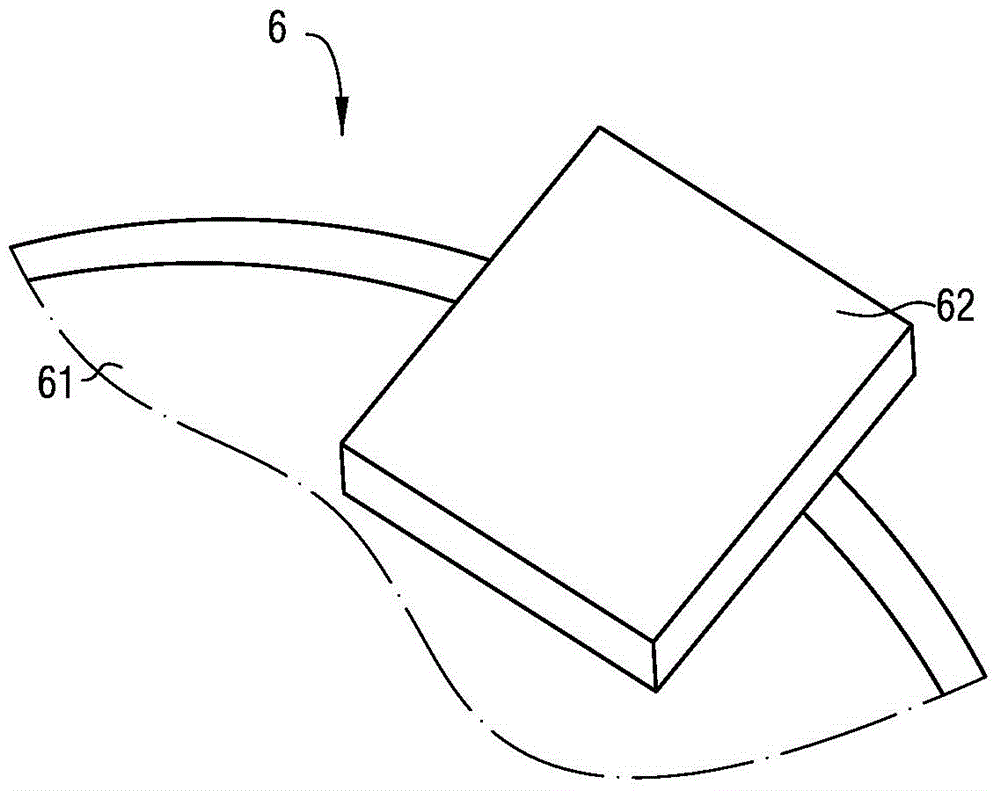

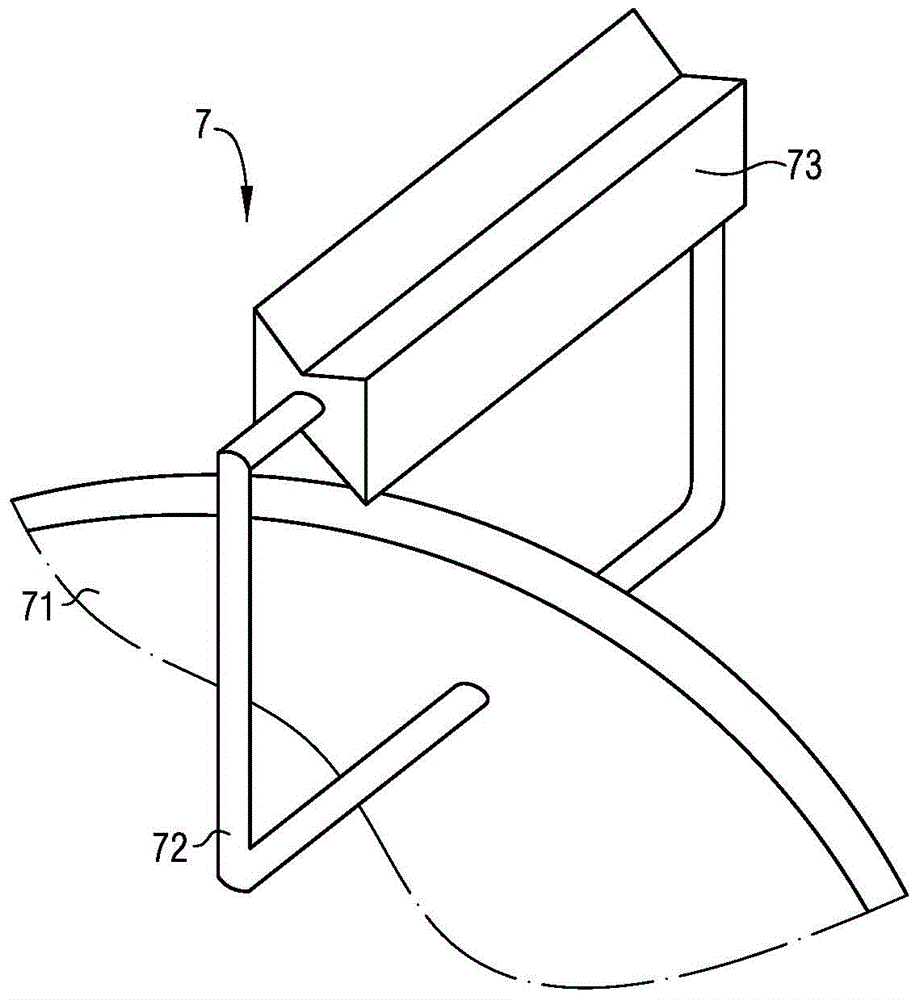

[0021] figure 1 It is a schematic structural diagram of an integrated equipment for pulverizing and screening pharmaceutical raw materials according to a specific embodiment of the present invention, figure 2 for figure 1 A schematic diagram of part of the structure of the first-stage grinding hammer shown. see Figure 1-2 As shown, an integrated equipment for crushing and screening pharmaceutical raw materials provided by the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com