A cable absorbing layer coating system and coating method thereof

A wave-absorbing layer and coating technology, applied in the cable wave-absorbing layer coating system and its coating field, can solve the problems of inability to coat and process cables, and achieve good uniformity, high coating efficiency, and uniform coating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

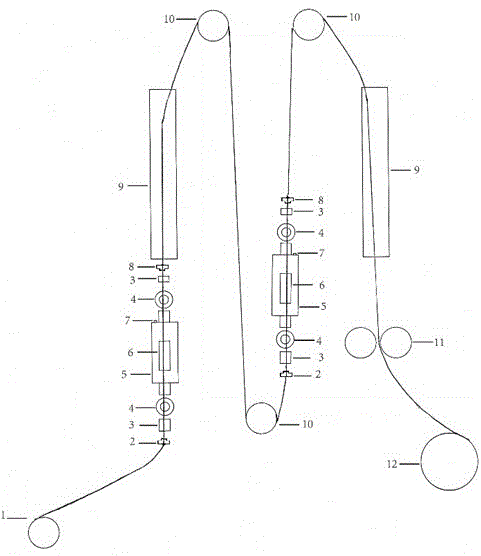

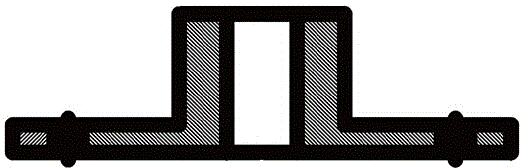

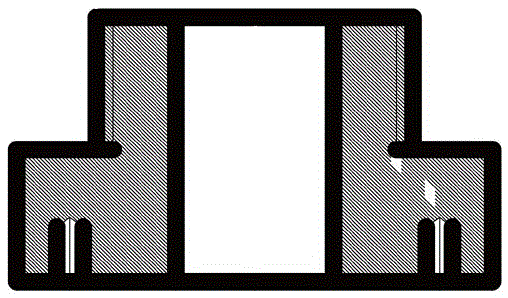

[0013] refer to figure 1 , The cable absorbing layer coating system includes a pay-off shaft 1, two coating devices, two sintering furnaces 9, three guide wheels 10, a traction wheel 11 and a take-up shaft 12; the coating device includes a wire passing die 2. The liquid storage tank 5 and the liquid scraping die 8, wherein the wire passing die 2 and the liquid scraping die 8 are respectively fixed on the bottom and top of the liquid storage tank 5 through the fastening flange 3 and the sealing rubber ring 4, and the upper end of the liquid storage tank 5 There is a liquid filling hole 7, and a transparent window 6 is provided in the middle; the cable enters the liquid storage tank 5 through the wire passing die 2 of the first coating device through the pay-off shaft 1, and then enters the first sintering furnace 9 through the liquid scraping die 8, The cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com