Composite absorbing material based on 3D printing and its application

A composite wave absorbing material and printing material technology, applied in the field of building materials, can solve the problems of destroying collective tissue, inconvenient to use mold forming, and high requirements, and achieve the effect of ensuring wave absorption effect and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Take sludge power generation fly ash and ash, and XRD method to detect its composition, the results are shown in Table 1.

[0069] Table 1

[0070]

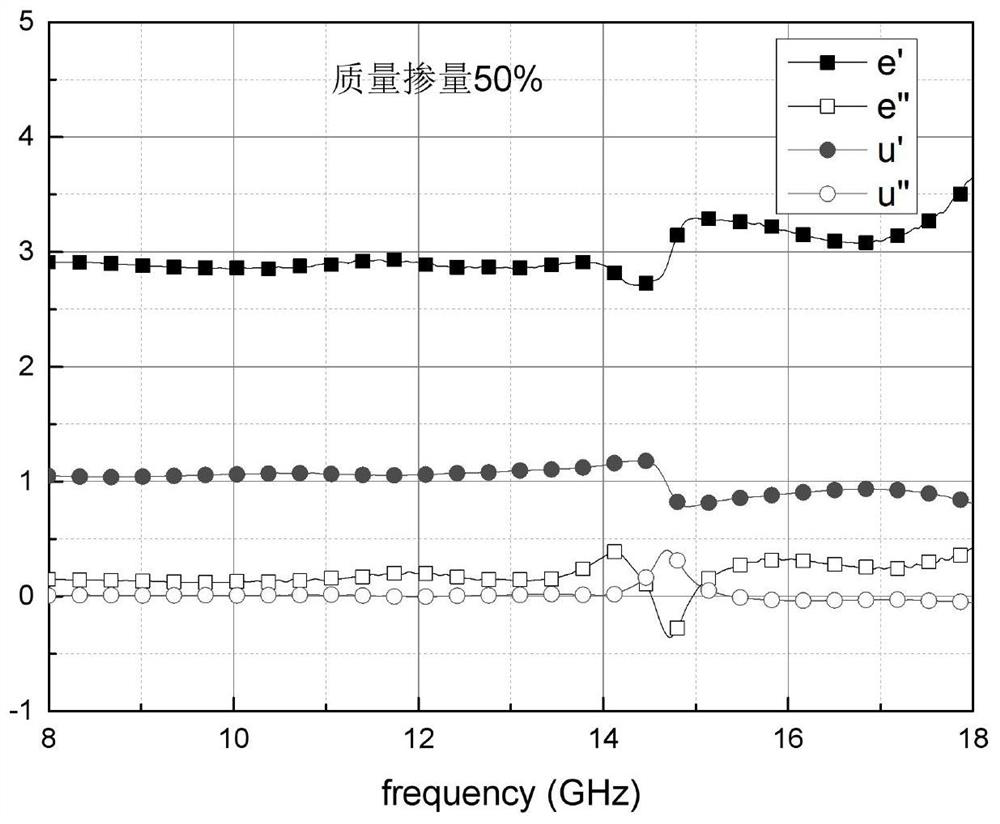

[0071] The electromagnetic parameters of sludge power generation fly ash were detected by the coaxial method. The mass content of fly ash and paraffin in the test sample was 50%. The results are as follows: figure 1 shown. Except for the 12.5-15GHz frequency band, the imaginary part of the permittivity is basically between 0.2-0.3, and the imaginary part of the magnetic permeability is basically 0. There is a certain dielectric loss performance in this frequency band; in the 12.5-15GHz frequency band, the dielectric constant Both the magnetic permeability and the magnetic permeability have great changes, especially the imaginary part of the magnetic permeability, which has increased significantly, indicating that there is a more obvious magnetic loss characteristic in this frequency band.

Embodiment 2

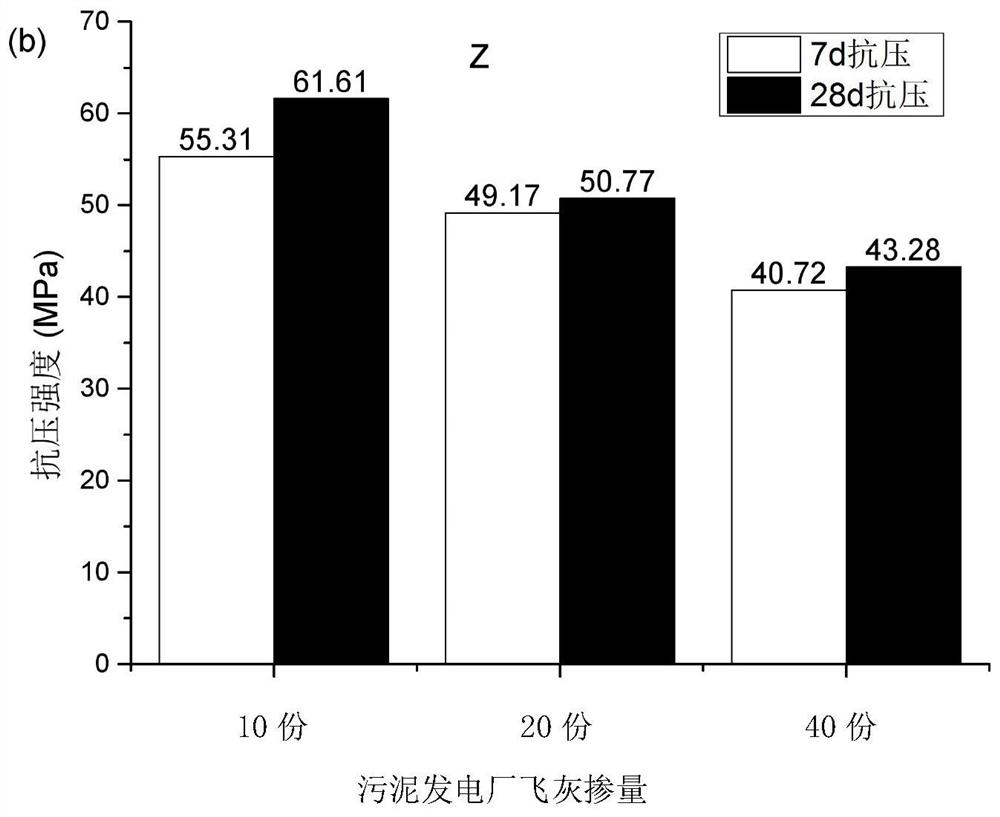

[0073] Composite absorbing materials based on 3D printing, including: PO42.5 ordinary portland cement 60 parts, sludge power plant fly ash 10, 20, 40 parts, quartz sand 60 parts, polycarboxylate superplasticizer 0.6 parts , 20 parts of water.

[0074] Shaped to 40*40*160mm 3 The triple module test block.

[0075] Test the compressive performance of triple mold test blocks 7d and 28d, the results are as follows figure 2 shown.

[0076] With the increase of the fly ash content of the sludge power plant, the mechanical strength of the material decreases, and the cover time needs to be extended. The fly ash content of the sludge power plant is less than 40 parts, which can better maintain the required strength.

Embodiment 3

[0078] Composite absorbing materials based on 3D printing, including main printing materials and auxiliary printing materials;

[0079] The main printing material comprises the following components by weight:

[0080] PO42.5 ordinary Portland cement 70 parts, sulphoaluminate cement 10 parts, silica fume 10 parts, sludge power plant fly ash 10 parts, quartz sand 120 parts, polycarboxylate superplasticizer 1 part, water 30 parts, 1.5 parts of carbon black.

[0081] The secondary printing material comprises the following components in parts by weight:

[0082] 95 parts of epoxy resin, 10 parts of carbon black.

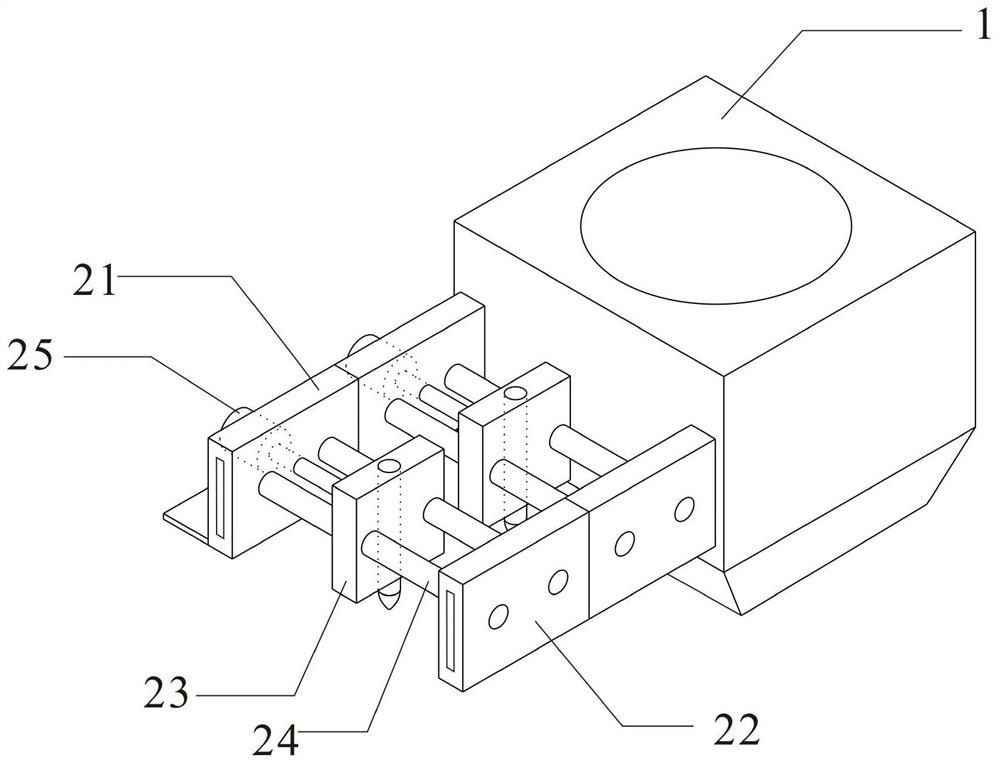

[0083] Use the following printheads to print composite absorbers:

[0084] Such as Figure 3-7 As shown, the print head includes a main extrusion head 1 and a sub-extrusion head assembly;

[0085] The top of the main extrusion head 1 is the main feed port, the bottom is the main extrusion port, and the main feed port is connected to the main extrusion port; the side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com