A method for treating zinc smelting sludge by microwave method

A technology of zinc smelting and microwave method, applied in the field of comprehensive utilization of resources and environmental protection, can solve the problems of high environmental risk, high energy consumption, low efficiency, etc., and achieve the effect of overcoming high energy consumption, ensuring heating efficiency, and ensuring recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

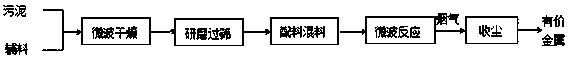

[0021] The microwave treatment method for zinc smelting sludge described in this embodiment specifically includes the following steps:

[0022] 1) Pretreatment and batching and mixing: take the zinc smelting sludge from plant 1 (the composition analysis results are listed in Table 1) and auxiliary materials, the drying microwave output power is 1200W, and the drying time is 15min; the drying microwave output power range of auxiliary materials is 500W, drying time is 8min. The dried sludge and auxiliary materials were ball milled and sieved with a mesh size of 180 meshes, and the under-sieved materials were prepared and mixed according to the ratio in Table 2.

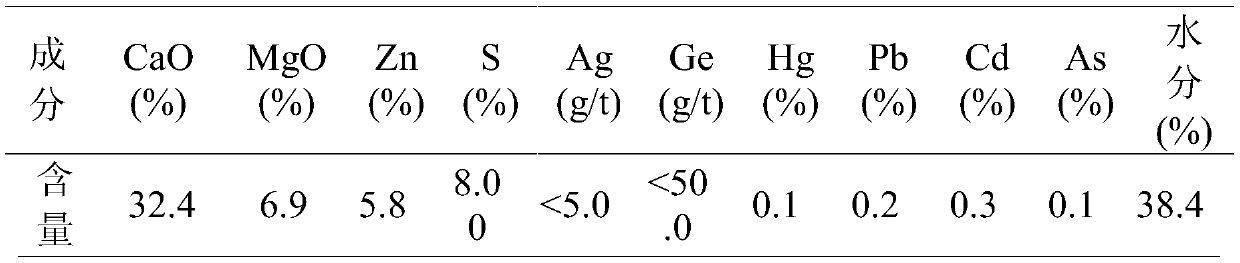

[0023] Table 1 Composition analysis table of zinc smelting sludge

[0024]

[0025] Table 2 Proportion 1#

[0026]

[0027]

[0028] 2) Recovery of valuable metals: The raw materials are heated and stirred by microwave, the stirring rate is 180rmp, the microwave output power is 3kW, the temperature in the rea...

Embodiment 2

[0033] The microwave treatment method for zinc smelting sludge described in this embodiment specifically includes the following steps:

[0034] 1) Pretreatment and batching and mixing: take the zinc smelting sludge from plant 2 (the composition analysis results are listed in Table 4) and auxiliary materials, the drying microwave output power range is 1500W, and the drying time is 10min; the drying microwave output power range of auxiliary materials It is 850W, and the drying time is 5 minutes. The dried sludge and auxiliary materials were ball milled and sieved with a mesh size of 200, and the under-sieved material was prepared and mixed according to the ratio in Table 5.

[0035] Table 4 Zinc smelting sludge composition analysis table

[0036]

[0037] Table 5 Proportion 2#

[0038]

[0039] 2) Valuable metal recovery: The raw materials are heated and stirred by microwave, the stirring rate is 200rmp, the microwave output power is 5kW, the temperature in the reactor i...

Embodiment 3

[0042] The microwave treatment method for zinc smelting sludge described in this embodiment specifically includes the following steps:

[0043] 1) Pretreatment and batching and mixing: Take the zinc smelting sludge from plant 3 (the composition analysis results are listed in Table 6) and auxiliary materials, the drying microwave output power range is 800W, and the drying time is 30min; the drying microwave output power range of auxiliary materials It is 400W, and the drying time is 15 minutes. The dried sludge and auxiliary materials are ball milled and sieved with a mesh size of 160 mesh.

[0044] Table 6 Zinc smelting sludge composition analysis table

[0045]

[0046] Table 7 ratio 3#

[0047]

[0048] 2) Valuable metal recovery: The raw materials are heated and stirred by microwave, the stirring rate is 260rmp, the microwave output power is 6kW, the temperature inside the reactor is 920°C, and the dust generated is collected by a combination of high temperature resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com