Method for precision plastic forming and precision heat treatment of waveform elastic element

A technology of elastic element and plastic forming, which is applied in the field of precision plastic forming and precision heat treatment of QBe2 beryllium bronze wave elastic element, which can solve the problems of wave elastic element elastic force and height dimension control, poor stability and other problems, so as to facilitate the selection of elastic force and elastic force The effect of good consistency, improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

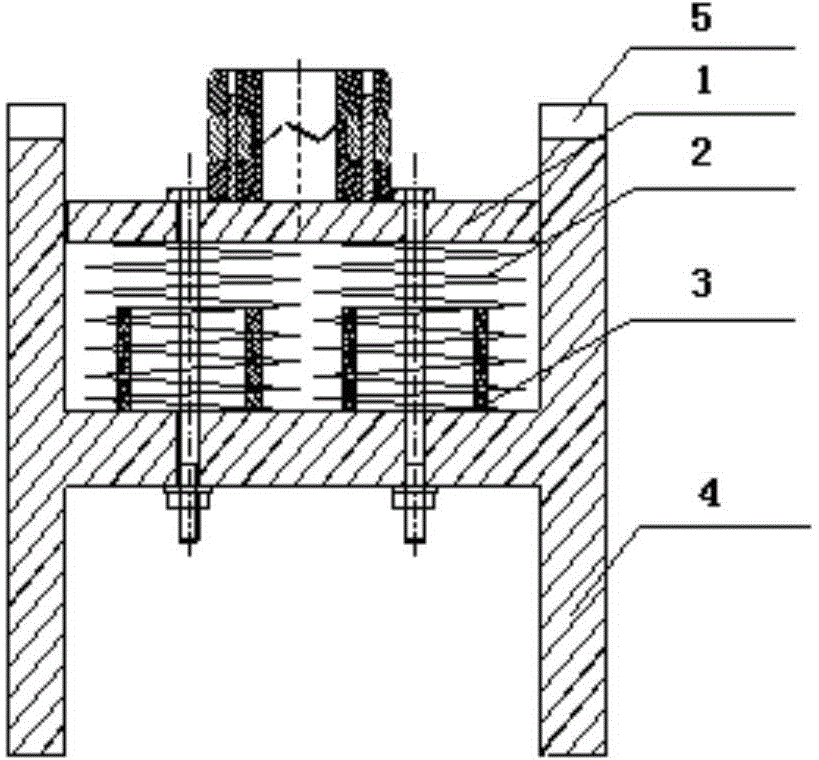

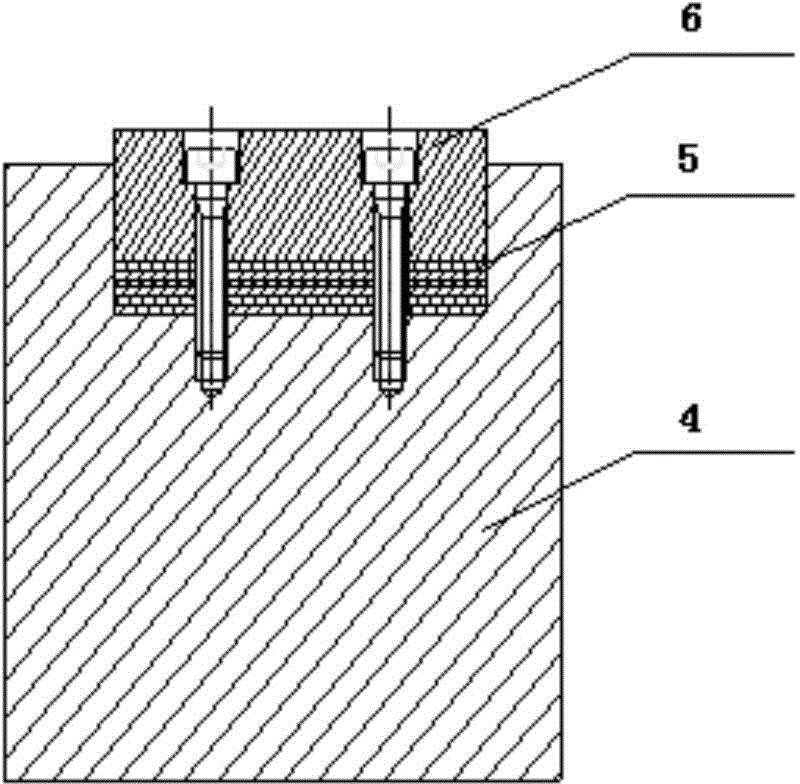

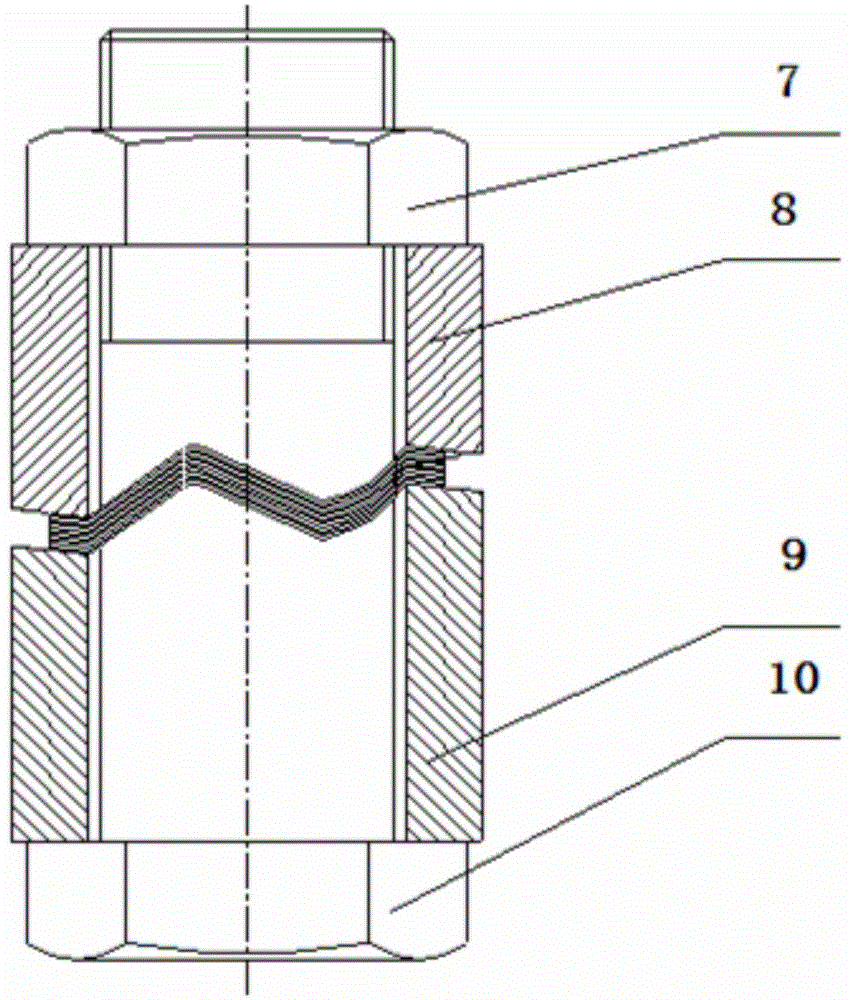

[0047]A molding force control device for precision components, including a support pad 1, a spring 2, a support body 4, an adjustment gasket 5, and a limit block 6; the support body 4 includes a base and side walls perpendicular to the base and arranged at both ends of the base , between the side walls specifically match with the side length of the support pad 1, so that the support pad 1 can slide up and down along the side wall of the support body 4, and the base of the support pad 1 and the support body 4 is provided with Four springs 2, the support pad 1 is limited in the direction parallel to the base of the support body 4 through the limit rod passing through it, the diameter of the limit rod matches the opening aperture on the support pad 1, and is fixed on The base of the support body 4, the two ends of the limit rod protrude from the support plate 1 and the base of the support body 4 under the uncompressed state of the spring 2, the extended part of the limit rod is a ...

Embodiment 2

[0050] A method for precision plastic forming and precision heat treatment of a wave elastic element, comprising the following steps:

[0051] Step 1. According to the size requirements of the part, the expanded shape is processed as

[0052] Step 2. Clean the workpiece with gasoline to make the surface of the workpiece free of dirt and oil stains;

[0053] Step 3, if figure 1 , 2 The precision component molding force control device shown is placed on the workbench of the hydraulic press, and the cleaned parts are placed between the upper and lower dies of the stamping die (existing dies can be used, or customized according to requirements), and the end face of the stamping die A die hole is provided, the stamping die is placed on the support plate 1 of the precision component forming force control device, and the steel ball is placed on the die hole of the stamping die;

[0054] Step 4. Compress the precision component forming force control device under the pressure of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com