Laser real-time deviation correction device and deviation correction method

A laser, high-speed technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of reduced production efficiency, waste, and non-compliance of amorphous silicon thin-film solar cell chips, to improve processing efficiency, time consumption, etc. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

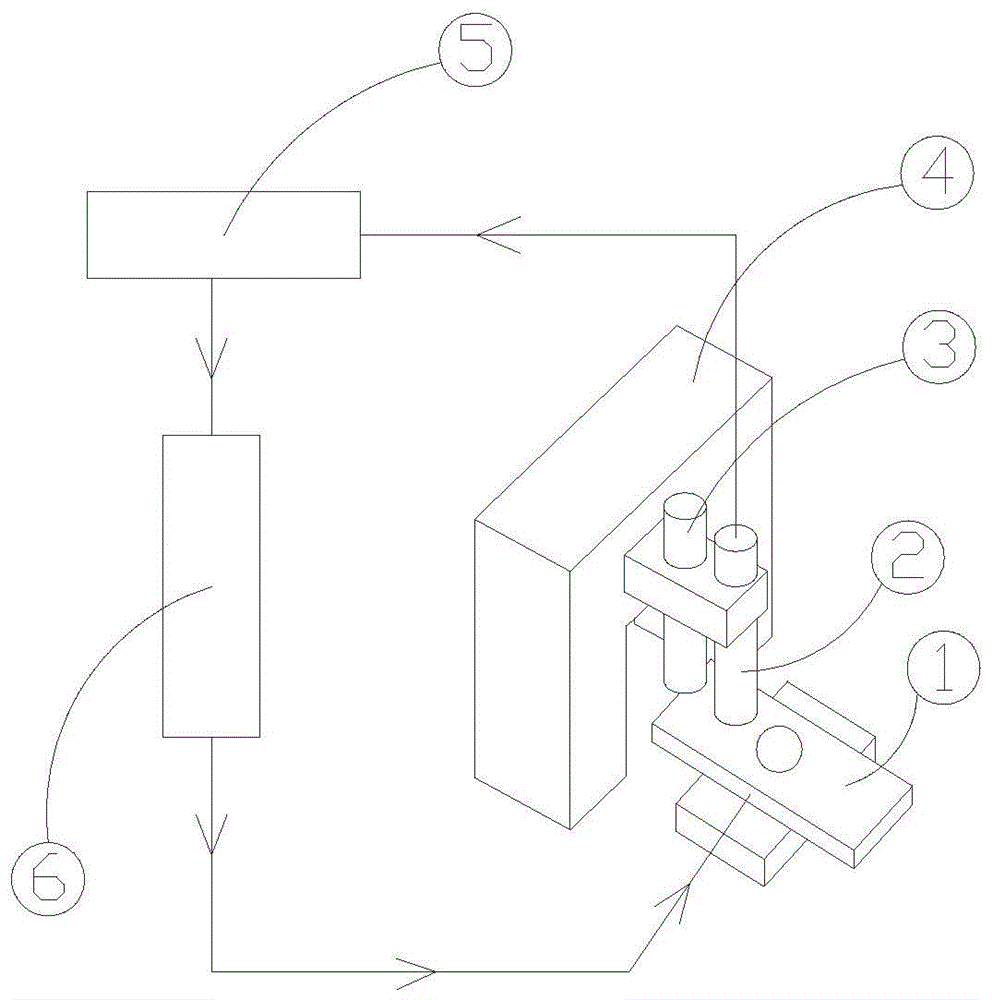

[0022] Such as figure 1 As shown in the real-time laser deviation correction device, there is a marble beam 4 above the moving working platform 1, and the alignment high-speed lens 2 and the laser processing head 3 are installed on the marble beam 4. The alignment high-speed lens 2 is produced by OLYMPUS Olympus in Japan LCPLN50XIR lens, motion control unit 6 is ACS main controller SpiiplusNtm-16000000NNN-S, motion working platform 1 is an X-Y axis motion platform, including the Y axis unit in the cutting direction and the X axis unit in the fixed distance moving direction combined with it; alignment The high-speed lens 2 and the laser processing head 3 are facing the moving working platform 1, and the alignment high-speed lens 2 and the laser processing head 3 are connected to the computer 5 through communication. The unit 6 is connected in communication, and the motion control unit 6 is connected with the motion working platform 1 under control. Laser real-time deviation co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com