Metal part internal crack repairing method

A repair method and technology for internal cracks, applied in the field of crack repair, can solve problems such as low healing rate, poor healing quality, and inconspicuous healing phenomena, and achieve the effects of high healing rate, short time-consuming, and simple and easy treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0016] A method for repairing internal cracks in metal parts of the present invention is aimed at the through-type crack damage that occurs in stainless steel rectangular thin plate parts, and the crack damage parts with unilateral cracks or central cracks whose maximum distance between the two sides of the crack should be within the size range of 20 μm designed for repair.

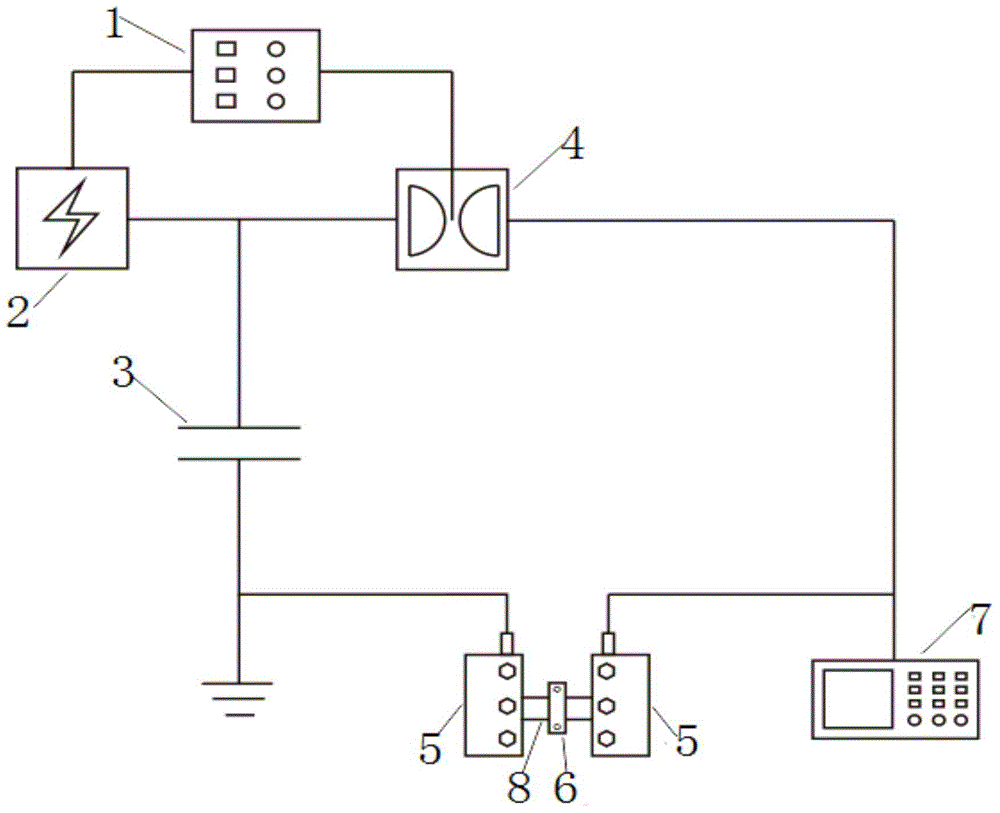

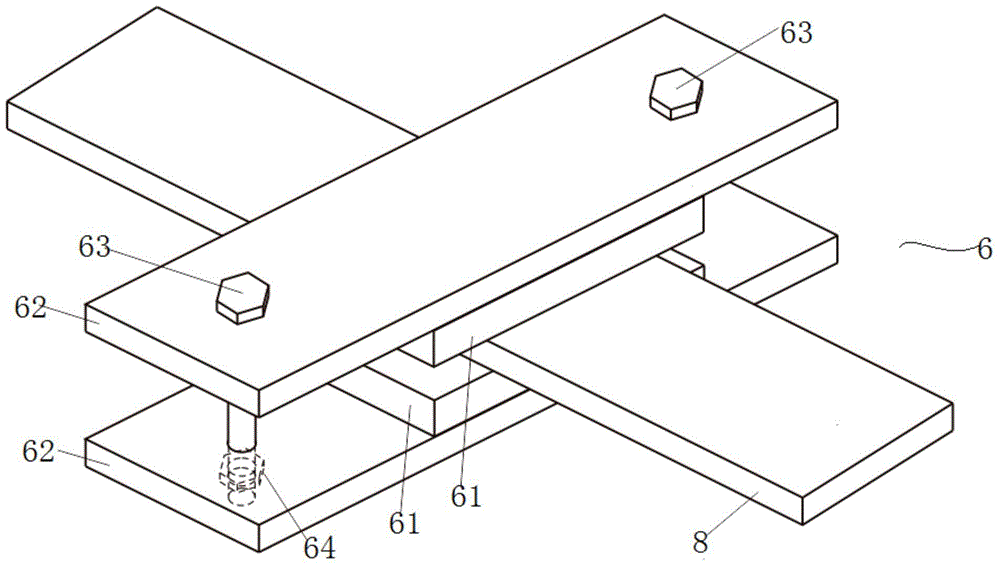

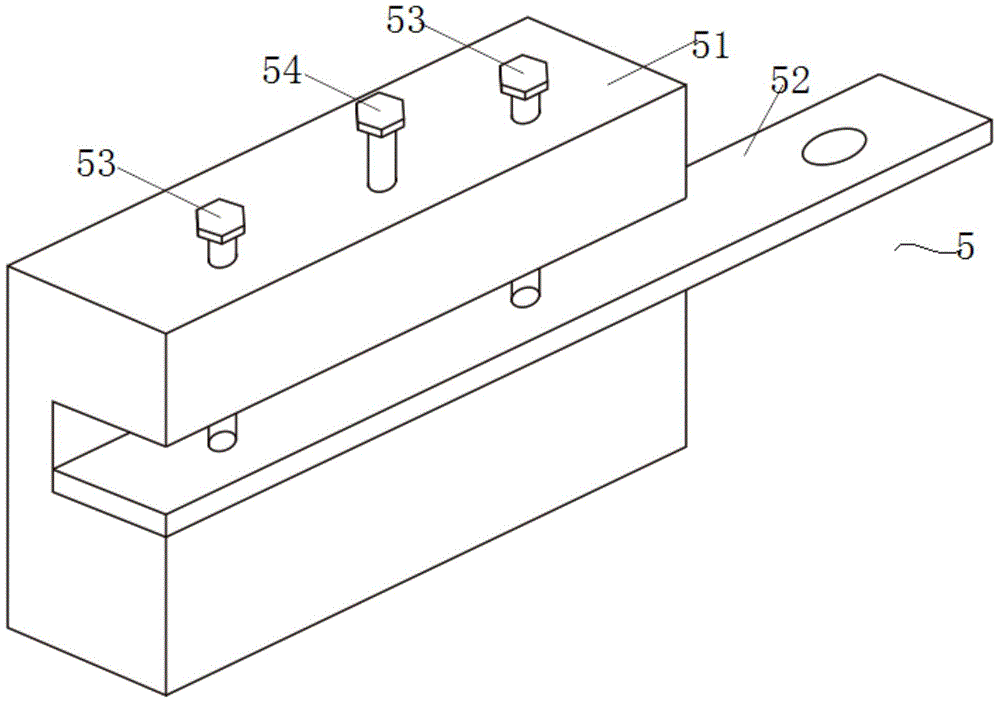

[0017] Such as figure 1 As shown, the present invention repairs the internal cracks of metal parts by applying the pulse current impact device of "Design and Experimental Research of Pulse Current Impulse Device published by Peng Yanfang in 2013" [D]. Dalian: Dalian University of Technology". The improvement point is that a parts protection fixture is added, and the repair device includes a controller 1, a charger 2, a capacitor bank 3, a high voltage switch 4, an equipment fixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com