Steel tube inner wall shot blasting cleaning machine

A technology of shot blasting cleaning machine and inner wall of steel pipe, which is applied in abrasive jet machine tools, used abrasive processing devices, abrasive materials, etc., can solve the problems of low automation of cleaning machines, and achieve good use effect, flexible rotation and cleaning efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

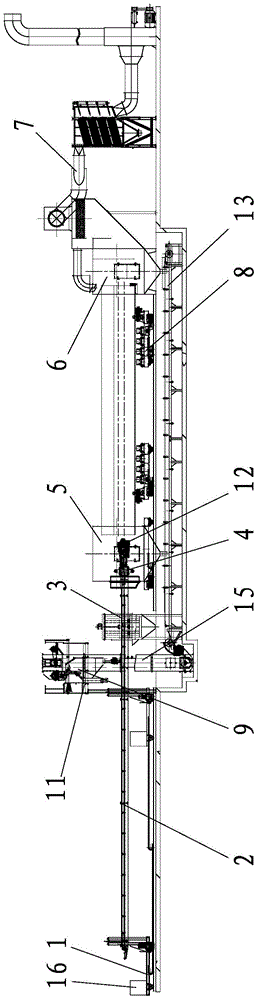

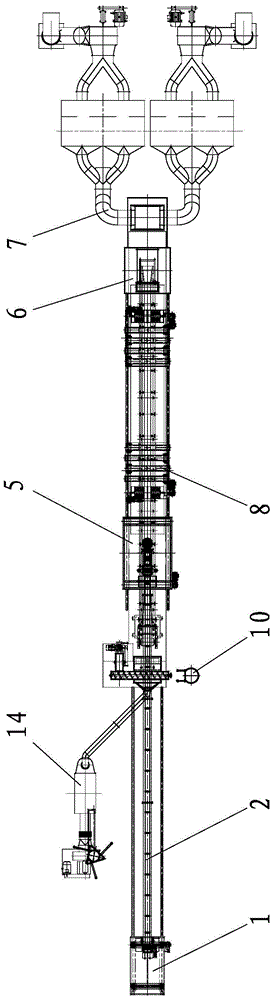

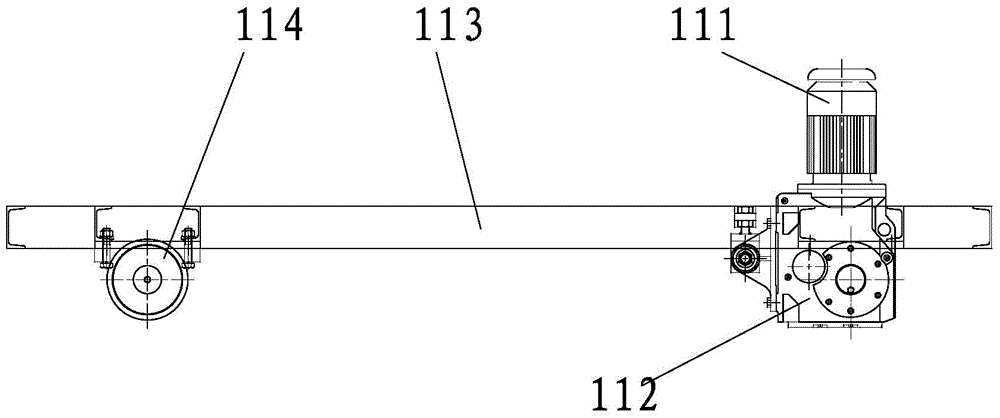

[0043] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. Such as Figure 1-15As shown, the invention discloses a steel pipe inner wall shot blasting cleaning machine, which includes a steel pipe support and conveying part, a movable sealing chamber 5, a shot blasting treatment part, and a shot sand recovery and separation part. The supporting and conveying part of the steel pipe includes a fixed sealing chamber 6, one end of the steel pipe workpiece is placed in the fixed sealing chamber 6, and the other end of the steel pipe workpiece penetrates into the movable sealing chamber 5 through the workpiece entrance, and the movable sealing chamber 5 is equipped with a hydraulic motor-driven The shot blasting device 12 is located at the end of the sand feeding mechanism 2 and is supported in the inner wall of the steel pipe workpiece by the rotary support mechanism.

[0044] The shot blasting process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com