Movable type soft and hard plastic material cutting device

A technology of cutting device and plastic material, applied in metal processing and other directions, can solve the problems of troublesome use, high cost, single structure, etc., and achieve the effects of convenient use, simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

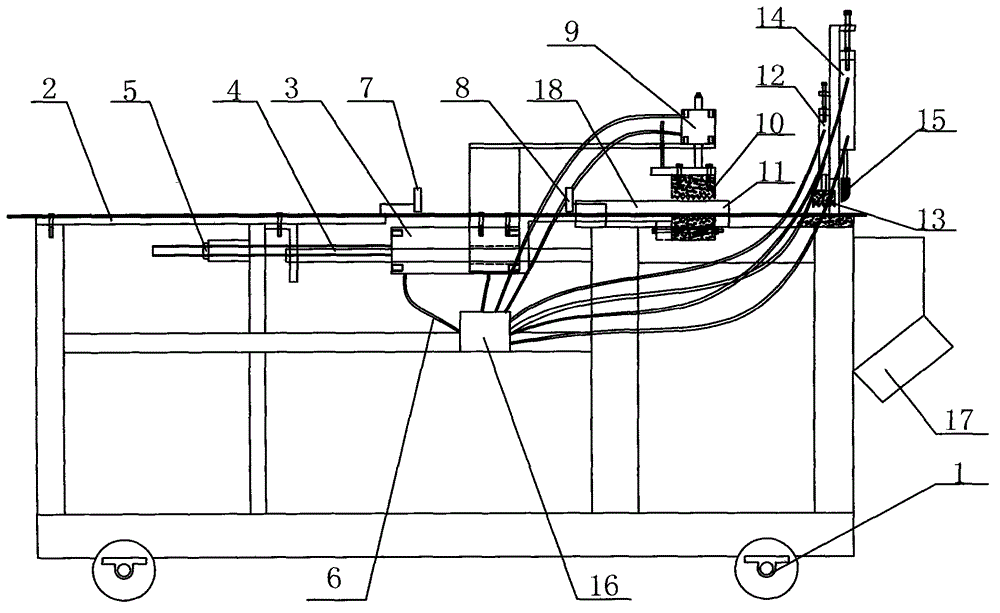

[0019] The mobile soft and hard plastic material cutting device includes a mobile frame 1, a stainless steel platform 2 on the top of the mobile frame 1, a sliding device, a pressing device, a cutting device and a solenoid valve group 16, wherein the sliding device and the solenoid valve The assembly is set at the lower end of the stainless steel platform 2, the pressing device is set at the middle of the stainless steel platform 2, and the cutting device is set at the front end of the stainless steel platform 2.

[0020] Wherein the sliding device is composed of the first cylinder 3, the slide bar 4 connected to the end of the first cylinder 3 and the slide table 18 matched with the slide bar 4, the limit device 5 located at the end of the slide bar 4, and the electromagnetic The compressed air pipe 6 connected to the valve group 16 is composed of a first proximity switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com