Multi-step continuous resin transfer molding method of rail vehicle composite material member

A composite component and resin transfer molding technology, which is applied in the design and manufacture of resin-based fiber-reinforced composite products, to achieve the effects of preventing air bubbles or dry spots, reducing injection pressure, and shortening curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

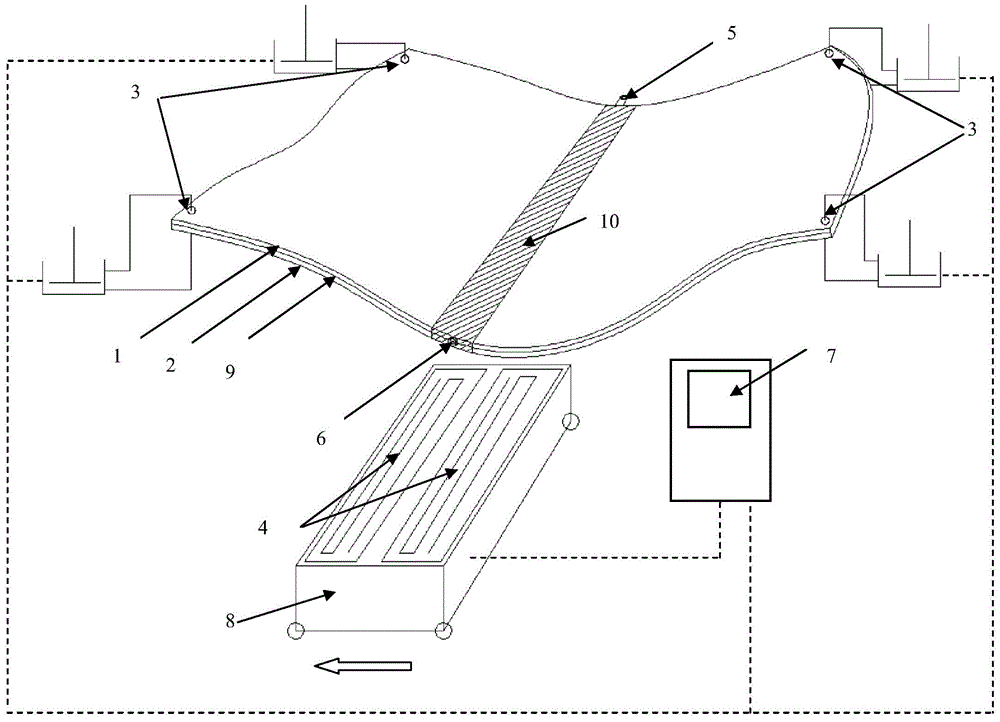

[0024] Such as figure 1 As shown, a multi-step continuous RTM molding method consists of an upper mold 1, a lower mold 2, a clamping and locking mechanism 3, two sets of movable electric heating tube arrays 4, several resin filling pipe joints 5, several pumping It consists of a vacuum joint 6 and a molding parameter control system 7. Wherein, the upper mold 1, the lower mold 2, and the clamping and locking mechanism 3 jointly constitute the molding mold for multi-step continuous RTM molding; the two groups of movable electric heating tube arrays 4 are installed on the platform of the mobile trolley 8, Placed under the lower mold 2 during work, it is used to heat the lower mold 2 to solidify the resin injected into the cavity of the mold. The moving speed and platform height of the mobile trolley 8 are set by the molding parameter control system 7; The control of the heating range of the designated area of the lower die 2 is achieved by adjusting the height of the platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com