Automatic guided vehicle capable of being automatically butted with working table surfaces at different heights

An automatic guidance and automatic docking technology, which is applied in the direction of vehicles with elevated loading platforms, can solve the problems of different liftable docking platforms, unresolved heights, and unmanned intervention, so as to improve automation and intelligence level, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

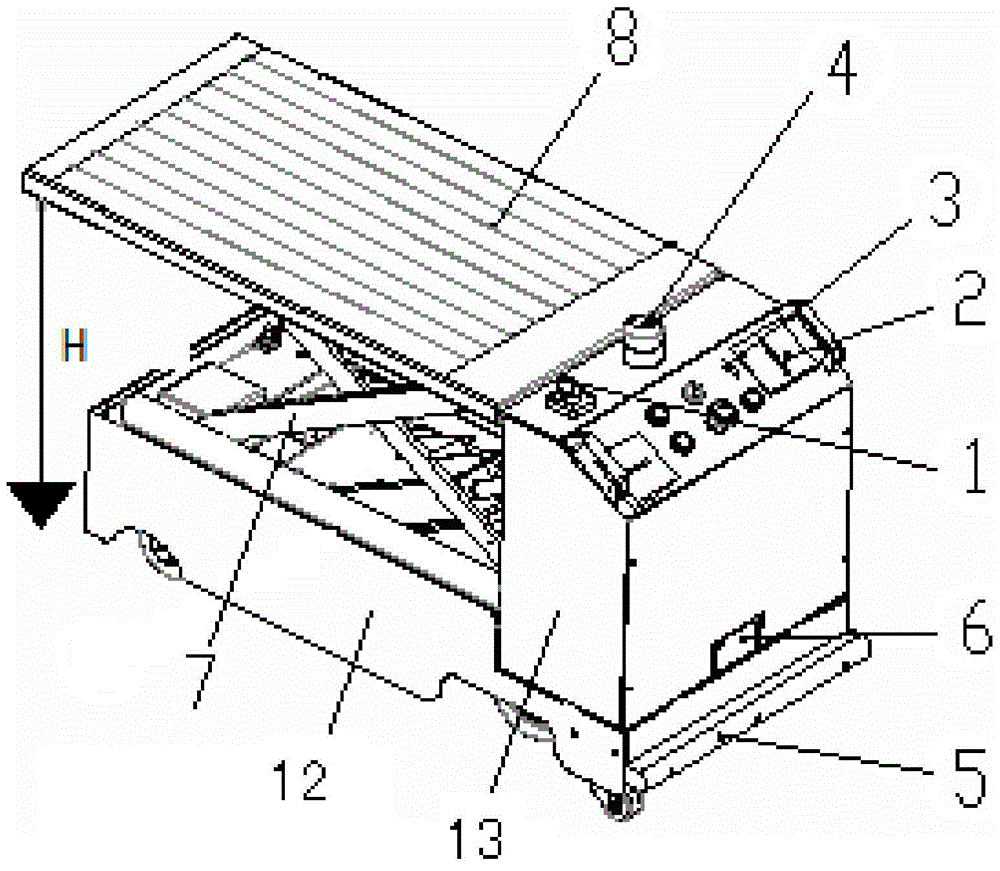

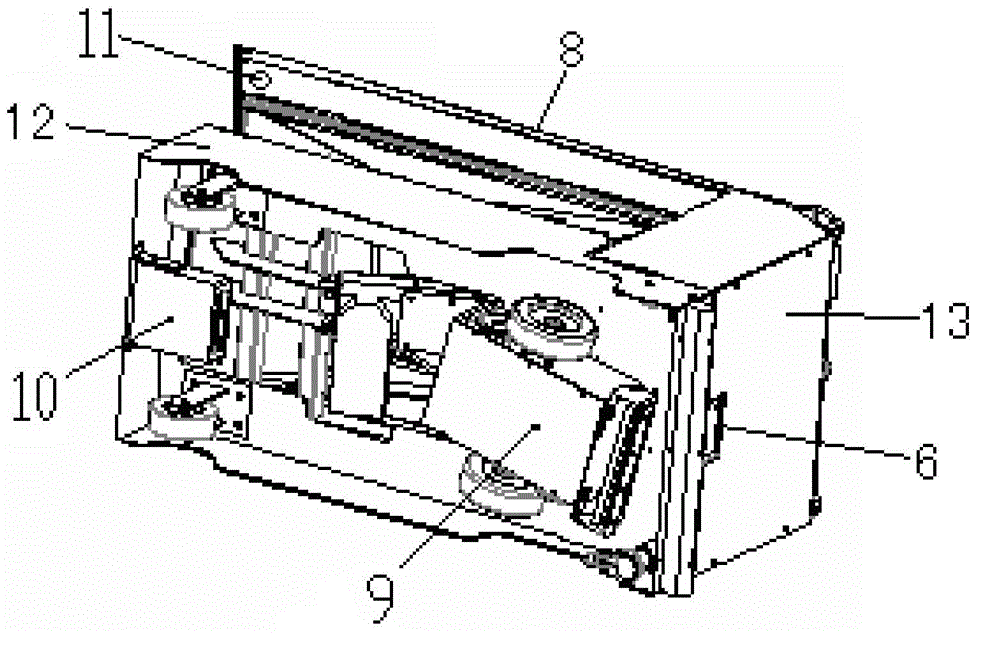

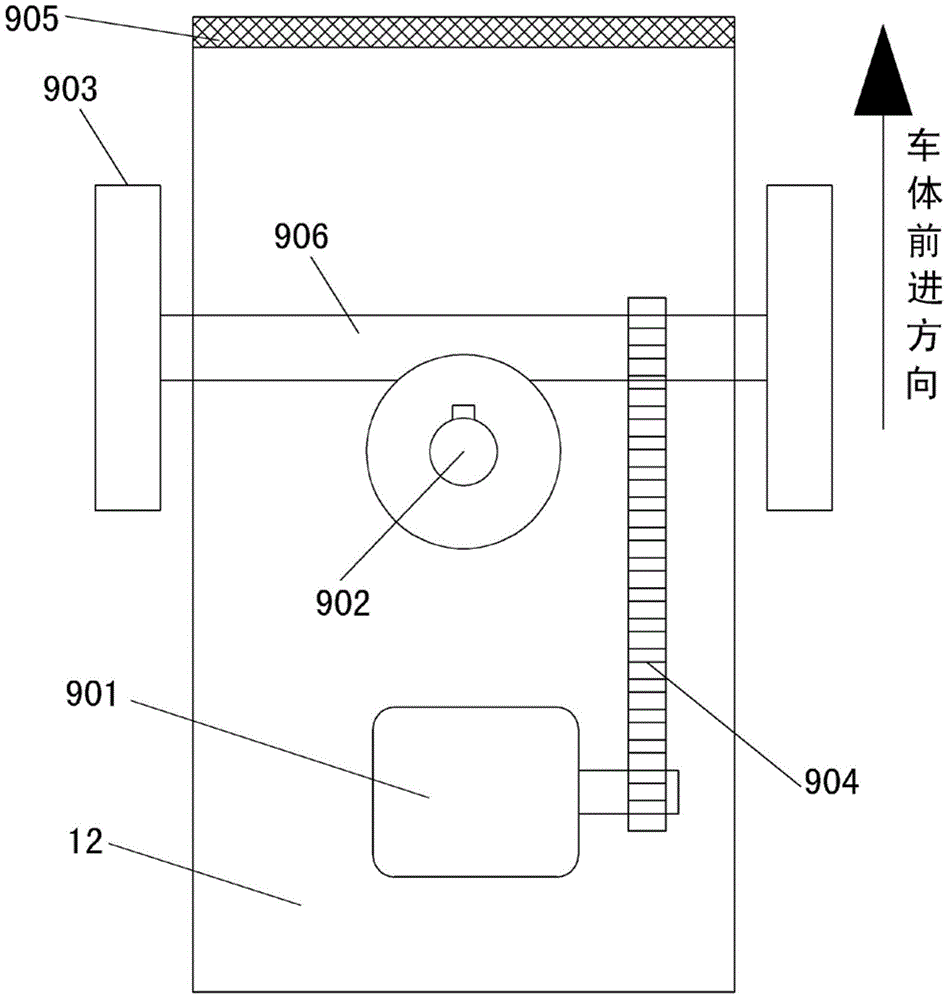

[0038] See attached Figure 1-11 , the automatic guided transport vehicle of the present invention that can automatically dock work surfaces of different heights includes a vehicle body 12 provided with a controller, the first end of the upper surface of the vehicle body 12 is provided with a vehicle head 13, and the bottom of the vehicle body 12 A drive assembly 9 is provided; on the vehicle body 12, a liftable loading platform 8 is provided behind the front 13; an ultrasonic sensor 11 is provided on the lower surface of the loading platform 8 for detecting The height H between the cargo platform 8 and the ground; the cargo platform 8 is connected to the car body 12 through the electric push rod 7, and the cargo platform 8 is driven by the electric push rod 7 Lifting; the bottom of the car body 12 is provided with an RFID card reader 10, which is used to read the RFID electronic tag on the ground;

[0039] A non-contact sensor 6 is arranged under the front of the front 13 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com