Pressure locking mechanism of passenger plane cabin door

A technology of locking mechanism and cabin door, which is applied in aircraft accessories, building structure, building fastening devices, etc., can solve the problems of large space occupied by flight lock mechanism, long development cycle, complicated pressure lock, etc., to save space and The effect of low weight, small number of parts, and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

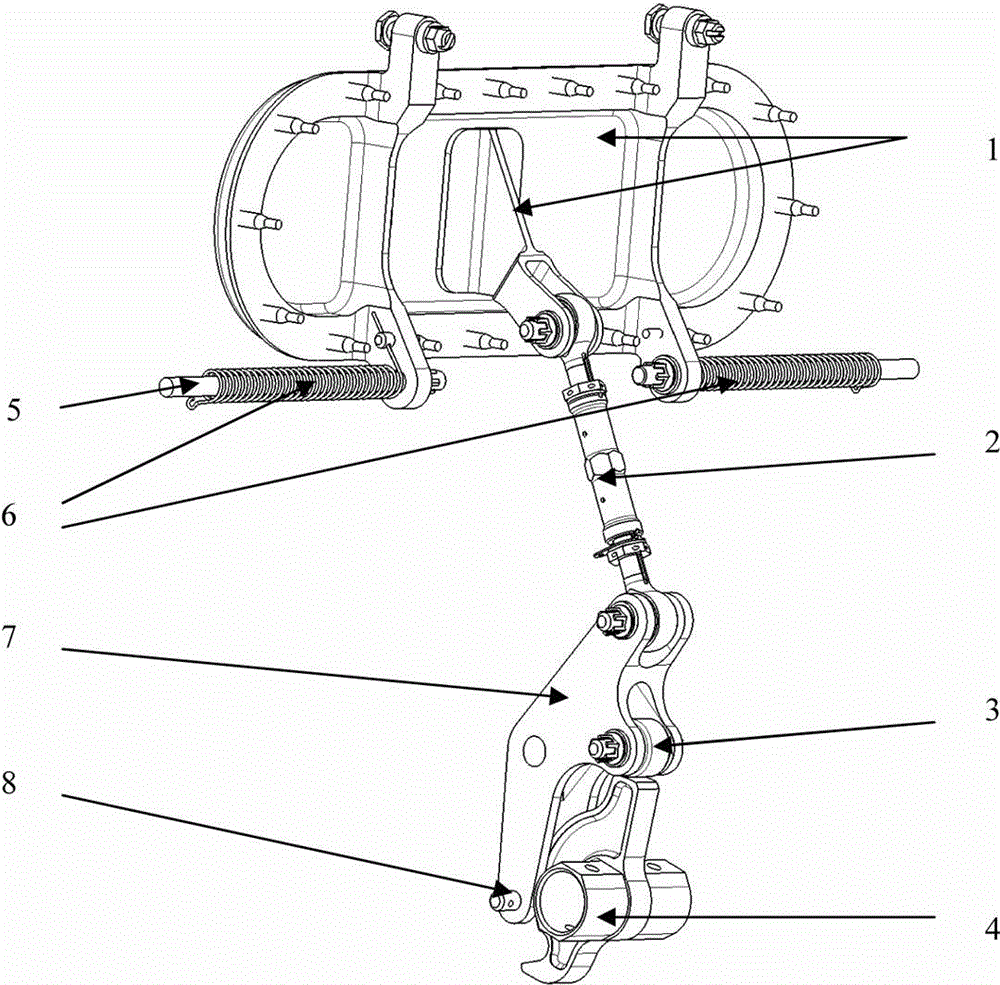

[0016] Such as figure 1 As shown, a pressure locking mechanism for a passenger aircraft cabin door has a vent assembly 1, a connecting rod 2, and a fork member 7 hinged to the cabin door structure, which are combined with the cabin door structure to form a four-bar mechanism; The fork-shaped ends of the fork-shaped piece 7 are respectively provided with an upper roller 3 and a lower roller 8, which form a cam-swing rod mechanism with the cam 4, and the cam 4 is coaxially connected with the door handle; the vent rotating shaft on the vent assembly 1 A torsion spring 6 is provided on 5, one end of the torsion spring 6 acts on the vent assembly 1 and the other end acts on the door structure, the force of the torsion spring 6 makes the vent assembly 1 have a tendency to open.

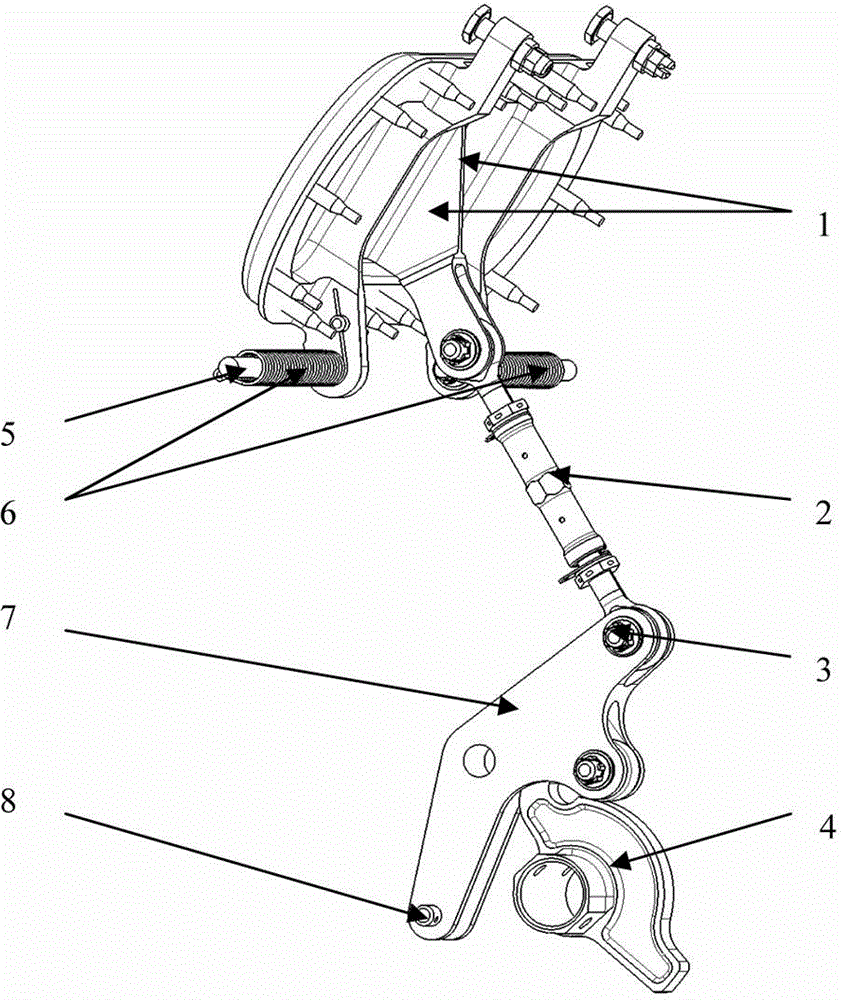

[0017] Such as figure 2 As shown, when it is normally opened, the torsion spring 6 drives the vent assembly 1 to open, and the upper roller 3 contacts the cam 4.

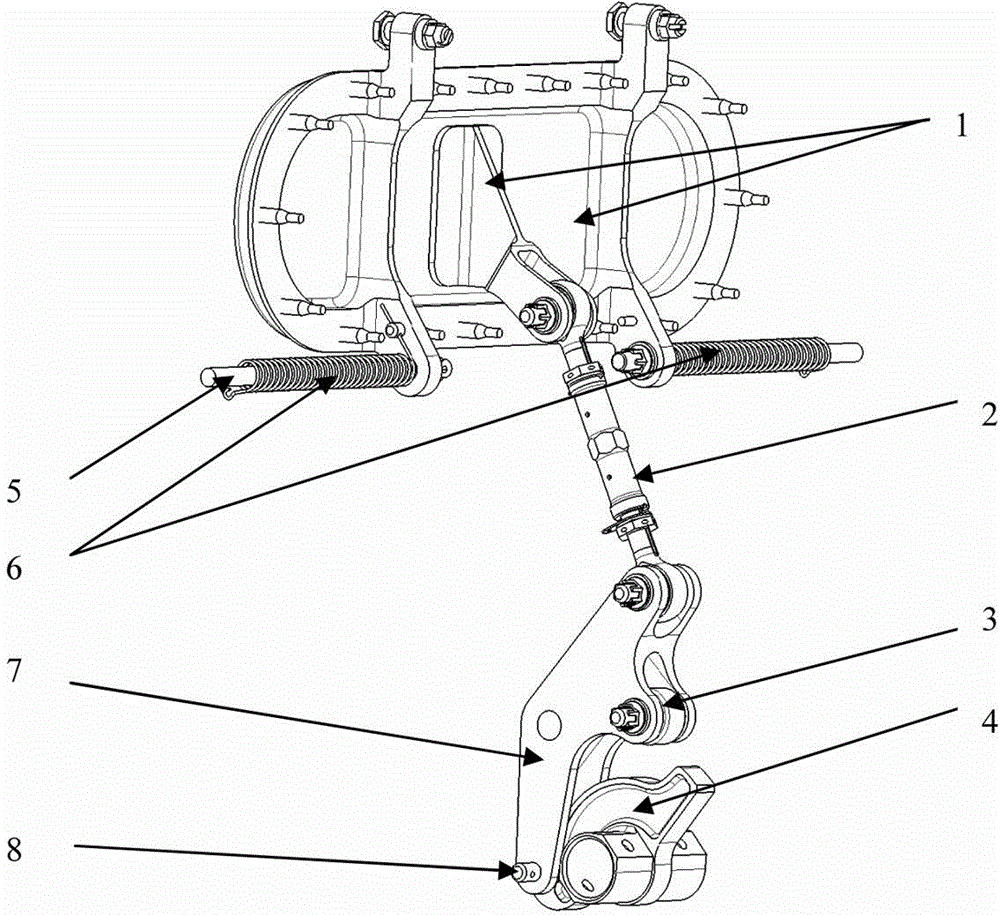

[0018] Such as image 3 As shown, when the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com