A supersonic air inlet anti-breathing structure

A technology of air inlet and supersonic speed, which is applied in the direction of combustion of the air inlet of the power unit, can solve the problems of the design, manufacture and installation of the blocking cover, the damage of the air flow sensor, the threat of the aircraft fuselage, etc., and achieve the reduction of overflow Flow phenomenon, compact overall structure, small size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

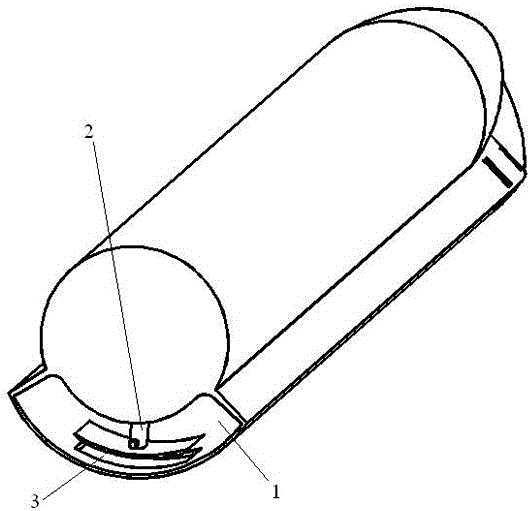

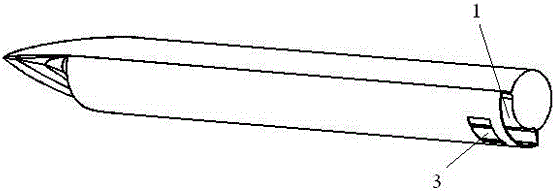

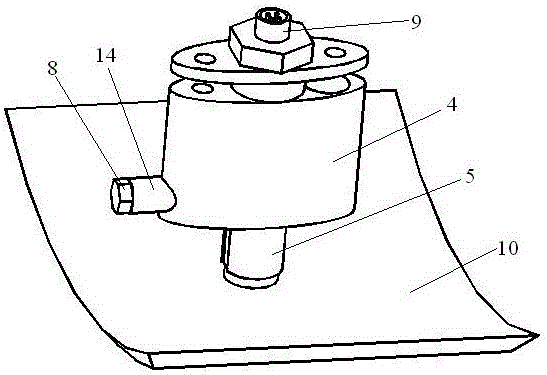

[0023] Example: see Figure 1 to Figure 9 .

[0024] An anti-puff structure for a supersonic air intake, comprising an air intake 1, an anti-puff action mechanism 2, an air discharge port 3 is opened near the exit of the air intake, and the anti-puff action mechanism 2 is located in the air intake 1. Next to the air port 3, the anti-breathing actuating mechanism 2 can close the air release port 3. The anti-breathing actuating mechanism 2 includes the actuating cylinder base 4, the actuating piston 5, the stop pin 6, the compression spring 7, the blind plug 8, the socket 9, and the cover The size of the plate 10 and the cover plate 10 are matched with the air outlet 3. A piston cylinder 11 is opened in the base body of the actuator cylinder 4. There is an actuating piston 5 at one end of the piston cylinder 11. There is a socket 9 at the other end of the piston cylinder 11. In the socket 9 Gunpowder 13 is filled between the actuating piston 5, the end of the actuating piston 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com