Inductive elevator operating panel

An operation panel and inductive technology, which is applied in the field of inductive elevator operation panel, can solve problems such as installation method, angle, position misreporting, complicated circuit wiring, failure, etc., and achieve simplified installation and debugging, circuit wiring, and good anti-interference ability , the effect of small environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

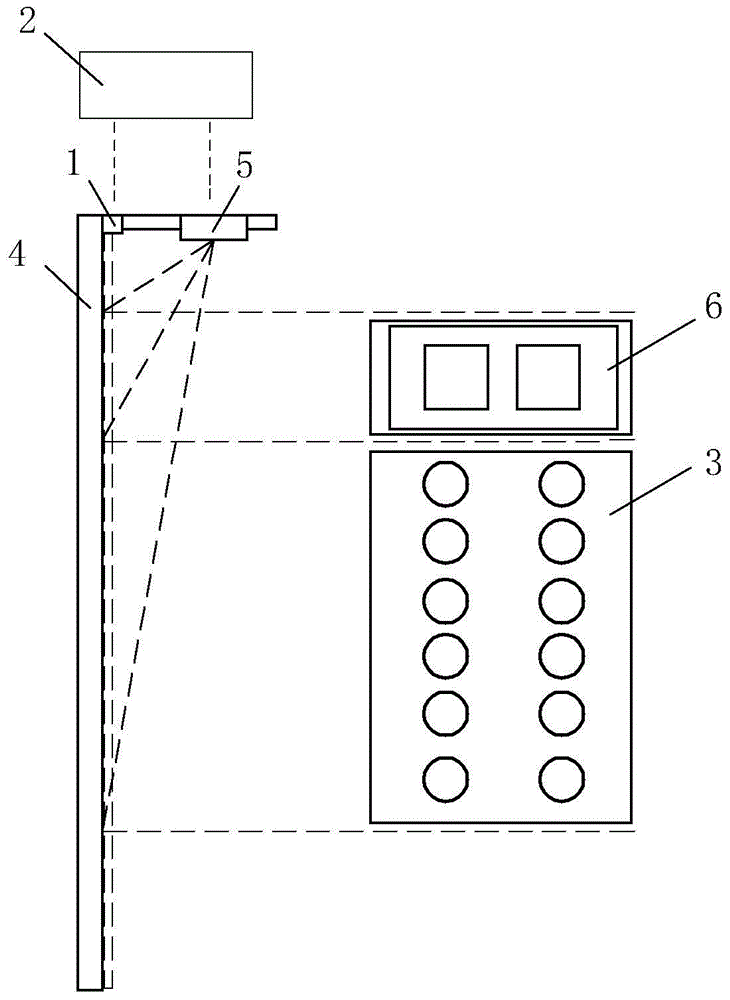

Embodiment 1

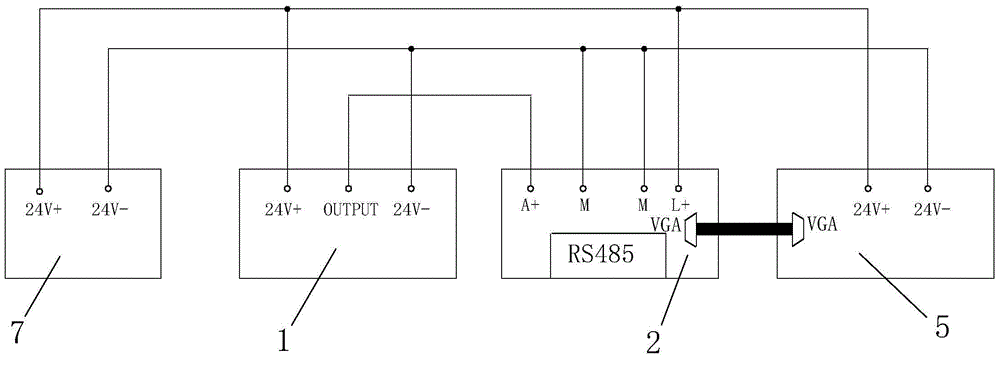

[0018] see figure 2 , the operation panel also includes a projection unit 5 and a power supply 7. In this embodiment, the detection unit 1 is a TOF photoelectric sensor, and the model is TOF / Spot-40-A produced by CEDES Holdings Co., Ltd.; The control unit 2 is PPCS03A produced by CEDES Holdings Co., Ltd.; the projection unit 5 is a BEAMER-SET projector with a model of ACER / C205; the power supply 7 is NES-50-24. The 24V+ terminal of the power supply 7 is respectively connected to the 24V+ terminal of the detection unit 1, the L+ terminal of the control unit 2 and the 24V+ terminal of the projection unit 5, and the 24V- terminal of the power supply 7 is respectively connected to the 24V- terminal of the detection unit 1 and the two terminals of the control unit 2. The M terminal is connected to the 24V- terminal of the projection unit 5 , and the power supply 7 provides power for the detection unit 1 , the control unit 2 and the projection unit 5 respectively. The A+ terminal ...

Embodiment 2

[0020] The simulated button panel 3 adopts a flat sticker marked with floor number characters and elevator control identifiers, and the detection unit 1 is the same as that in embodiment 1, and it cooperates with the simulated button panel 3 to simulate multiple columns on the inner wall of the bridge compartment 4 operating area. When the user puts his finger on the analog key panel 3 in a traditional way, the detection unit 1 collects the key operation signal on the analog key panel 3 and transmits it to the control unit 2, and the control unit 2 is connected to the elevator running circuit to make the elevator complete the corresponding operation. In this case, the display of the running status of the elevator is completed by the existing display circuit in the running circuit of the elevator. All the other are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com