A method and device for removing residual aluminum in mine water

A mine water and residual aluminum technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve toxicity and other problems, achieve low price, reduce dosage, and reduce residual aluminum content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

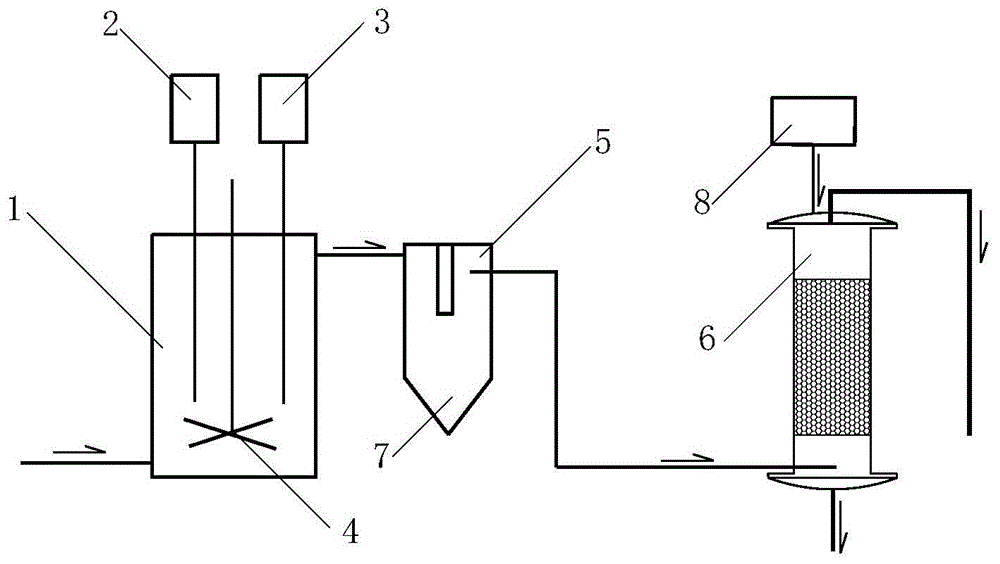

Image

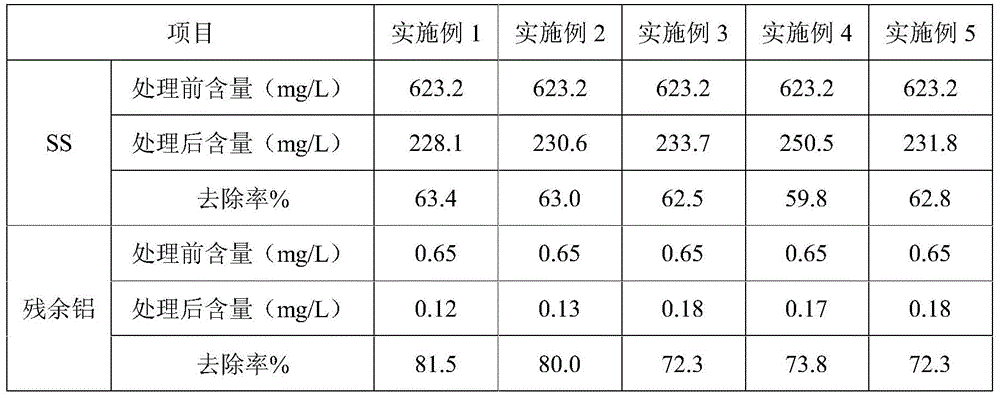

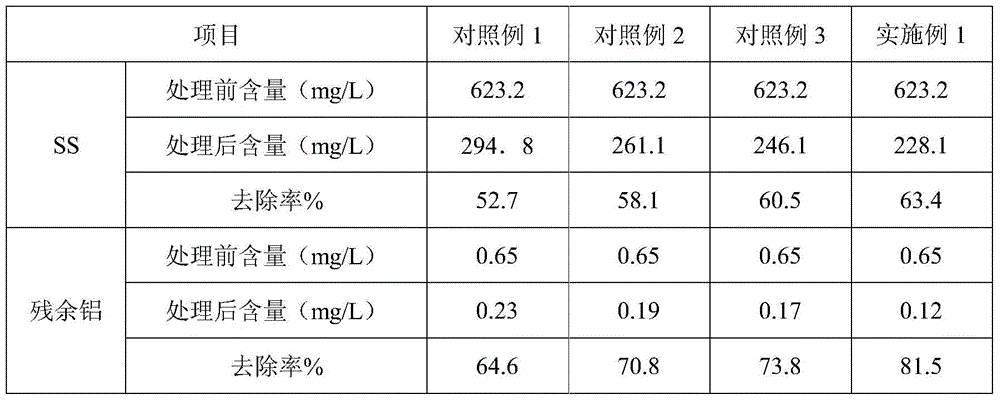

Examples

Embodiment 1

[0070] 1. Pump the mine water to be treated into the coagulation reaction tank. When the liquid level in the coagulation reaction tank reaches 50cm from the top of the pool, stop water intake; the size of the coagulation reaction tank is: 4000×5600×4500mm.

[0071] 2. Turn on the polyaluminum chloride dosing device and the activated carbon dosing device to coagulate the mine water. The dosage of polyaluminum chloride is 60mg / L, and the dosage of powdered lignite-based activated carbon is 5mg / L; Turn on the coagulation and stirring device to fully stir the mine water, first stir at a stirring rate of 200r / min for 2min, then reduce the stirring rate to 50r / min, and stir for 10min.

[0072] 3. The mine water after coagulation flows into the sedimentation tank by itself for static sedimentation. The time for static sedimentation is 20 minutes; the size of the sedimentation tank is: 4000×2000×4500mm.

[0073] 4. Pump the clear water after static precipitation treatment into the act...

Embodiment 2

[0075] 1. Pump the mine water to be treated into the coagulation reaction tank. When the liquid level in the coagulation reaction tank reaches 50cm from the top of the pool, stop water intake; the size of the coagulation reaction tank is: 4000×5600×4500mm.

[0076] 2. Turn on the polyaluminum chloride dosing device and the activated carbon dosing device to coagulate the mine water. The dosage of polyaluminum chloride is 70mg / L, and the dosage of powdered lignite-based activated carbon is 4.5mg / L ; Turn on the coagulation and stirring device to fully stir the mine water, first stir at a stirring rate of 220r / min for 3 minutes, then reduce the stirring rate to 65r / min, and stir for 8 minutes.

[0077] 3. The mine water after coagulation flows into the sedimentation tank by itself for static sedimentation. The time for static sedimentation is 15 minutes; the size of the sedimentation tank is: 4000×2000×4500mm.

[0078] 4. Pump the clear water after static precipitation treatment ...

Embodiment 3

[0080] 1. Pump the mine water to be treated into the coagulation reaction tank. When the liquid level in the coagulation reaction tank reaches 50cm from the top of the pool, stop water intake; the size of the coagulation reaction tank is: 4000×5600×4500mm.

[0081] 2. Turn on the polyaluminum chloride dosing device and the activated carbon dosing device to coagulate the mine water. The dosage of polyaluminum chloride is 80mg / L, and the dosage of powdered lignite-based activated carbon is 5.5mg / L ; Turn on the coagulation and stirring device to fully stir the mine water, first stir at a stirring rate of 180r / min for 4 minutes, then reduce the stirring rate to 40r / min, and stir for 15 minutes.

[0082] 3. The mine water after coagulation flows into the sedimentation tank by itself for static sedimentation. The time for static sedimentation is 25 minutes; the size of the sedimentation tank is: 4000×2000×4500mm.

[0083] 4. Pump the clear water after static precipitation treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com