A rare earth ion-doped high-density oxyfluoroborate germanate scintillation glass and its preparation method

A fluorooxoborogermanate and scintillation glass technology, applied in the field of luminescent materials, can solve problems such as pollution of the environment, restrictions, etc., and achieve the effects of simple preparation process, reduced preparation cost, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation process

[0035] The first step: the glass formula is B 2 o 3 -GeO 2 -Gd 2 o 3 -GdF 3 -LaF 2 , the specific glass composition of Example 1 is given in Table 1, and the glass luminescent center is Ce 3+ ;

[0036] Step 2: Mix the formula thoroughly and melt it in the air atmosphere at 1430°C for 3 hours by high-temperature melting method;

[0037] Step 3: Pour the above melt into a preheated 600°C stainless steel mold for casting;

[0038] Step 4: Place the above glass in a muffle furnace at 520°C for 10 hours for annealing;

[0039] Step 5: The above-mentioned primary scintillating glass is processed into 15×15×2mm after cutting, surface grinding and polishing 3 The scintillation glass of the present invention.

[0040] 2. Test

[0041] The photoluminescence spectra and X-ray excitation emission spectra of all scintillation glasses were obtained by using a fluorescence spectrometer (Hitachi F-7000, Ex slit 5.0nm, Em slit 5.0nm) and an X-ray ex...

Embodiment 1-5

[0044] Table 1. Glass composition of Examples 1-5

[0045]

Embodiment 2

[0047] The glass component of embodiment 2 is B 2 o 3 -GeO 2 -Lu 2 o 3 -GdF 3 -BaF 2 , the specific glass composition of Example 2 is given in Table 1, and the luminescent center is Tb 3+ Ions, the melting temperature is 1520°C, the melting atmosphere is air, the annealing temperature is 650°C, and the annealing time is 15 hours.

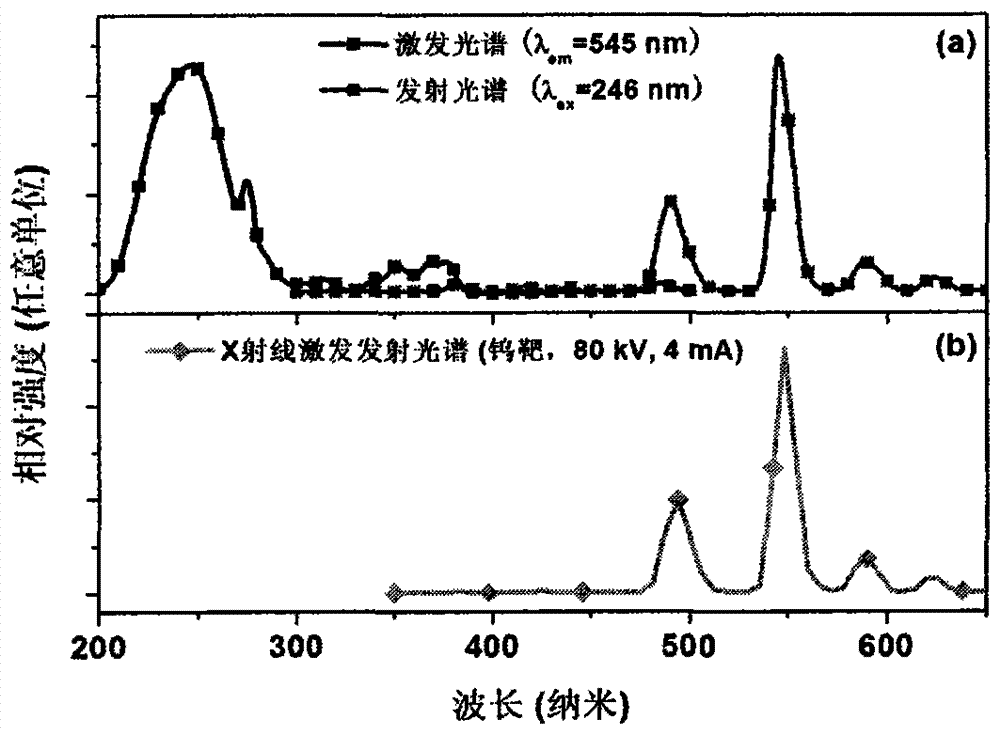

[0048] image 3 It is the photoluminescence and X-ray excitation emission spectrum of the scintillation glass of embodiment 2. From image 3 It can be seen from (a) that the four emission peaks at 490nm, 545nm, 588nm and 624nm in the emission spectrum correspond to Tb 3+ ion 5 D. 4 → 7 f J (J = 6, 5, 4, 3) optical transition, where 545nm ( 5 D. 4 → 7 f 5 ) wavelength has the maximum luminous intensity. And under X-ray (80kV and 4mA) excitation, obtain the scintillation light output of embodiment 2 scintillation glass, as image 3 (b) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com