A cement-based imitation sandstone product, its manufacturing method and fixture used in its manufacturing method

A production method and imitation sandstone technology, which is applied in the field of imitation sandstone products, can solve the problems of single texture effect, complex production method, complicated maintenance work, etc., and achieve the effect of good decoration effect, reasonable production method and outstanding texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

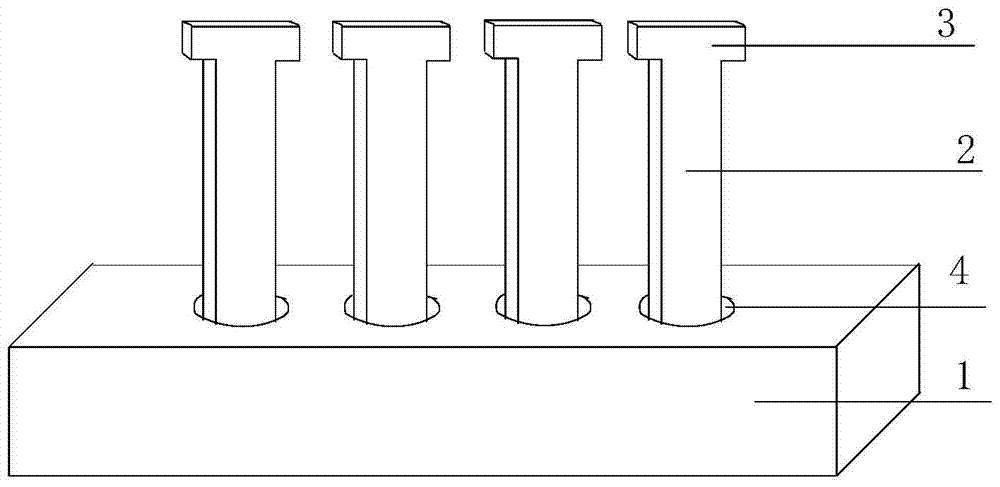

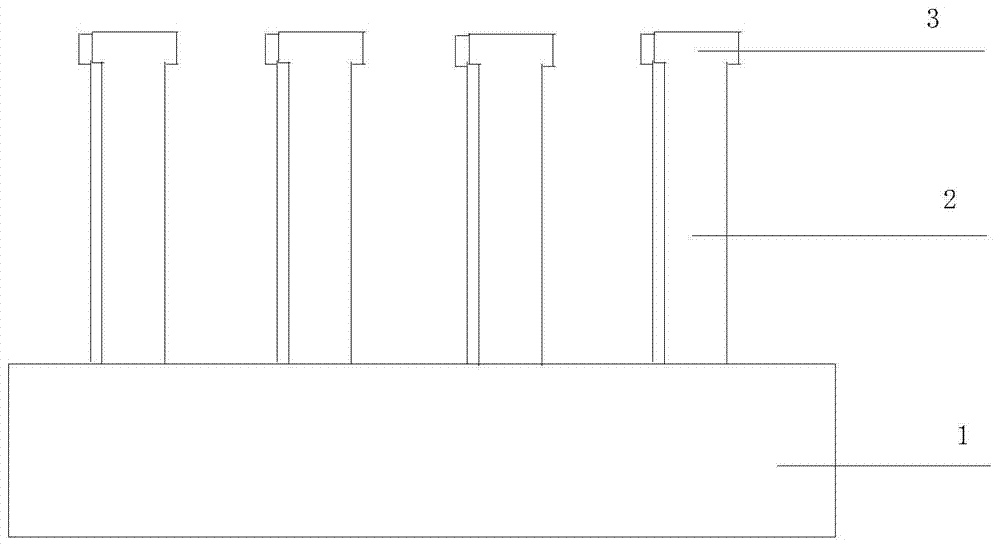

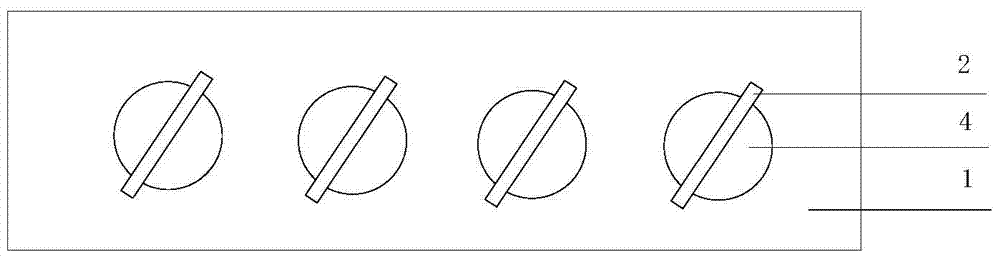

Image

Examples

Embodiment 1-

[0084] Example 1- Australian sandstone look

[0085] 1. The components of the main color mortar material and auxiliary color mortar material and their weight ratio and preparation requirements (1) The components of the main color mortar material and their weight ratio include:

[0086]

[0087] (2) The components and weight proportions of auxiliary color mortar material 1 include:

[0088]

[0089] (3) Components and weight proportions of auxiliary color mortar material 2 include:

[0090]

[0091]

[0092] (4) The preparation requirements of the main color mortar material and auxiliary color mortar material include:

[0093] The fluidity of the main color mortar is 200mm;

[0094] The fluidity of auxiliary color mortar material 1 and auxiliary color mortar material 2 is 230mm.

[0095] 2. Manufacturing method of cement-based imitation sandstone products

[0096] Step 1: prepare main color mortar material and auxiliary color mortar material according to the c...

Embodiment 2-

[0100] Example 2- imitation french petrified wood

[0101] 1. The components of the main color mortar and auxiliary color mortar and their weight ratio and preparation requirements

[0102] (1) The components and weight ratio of the main color mortar include:

[0103]

[0104]

[0105] (2) The components and weight ratio of auxiliary color mortar include:

[0106]

[0107] (3) The preparation requirements of the main color mortar material and auxiliary color mortar material include:

[0108] The fluidity of the main color mortar is 200mm;

[0109] The fluidity of auxiliary color mortar material is 200mm.

[0110] 2. Manufacturing method of cement-based imitation sandstone products

[0111] Step 1: prepare main color mortar material and auxiliary color mortar material according to the components in (1) and their weight ratio and preparation requirements;

[0112] Step 2: pouring the main-color mortar material into the inner cavity of the hard mold, and then pour...

Embodiment 3-

[0115] Example 3- Imitation Italian wood grain stone

[0116] 1. The components of the main color mortar and auxiliary color mortar and their weight ratio and preparation requirements

[0117] (1) The components and weight ratio of the main color mortar include:

[0118]

[0119] (2) The components and weight ratio of auxiliary color mortar include:

[0120]

[0121] (3) The preparation requirements of the main color mortar material and auxiliary color mortar material include:

[0122] The fluidity of the main color mortar is 180mm, and the color is light coffee;

[0123] The fluidity of auxiliary color mortar material 1 is 230mm, and the color is brown.

[0124] 2. Manufacturing method of cement-based imitation sandstone products

[0125] Step 1: prepare main color mortar material and auxiliary color mortar material according to the components in (1) and their weight ratio and preparation requirements;

[0126] Step 2: Vibrating and pouring the main-color mortar in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com