Material for high superposition of manganese-zinc ferrite core and preparation method thereof

A technology of manganese-zinc ferrite and high superposition is applied in the field of materials for high-superposition manganese-zinc ferrite cores and their preparation, and can solve the problem of low magnetic permeability at room temperature, which cannot meet the requirements of superimposed inductance of power transformers, and cannot meet the requirements of superimposed inductance of power transformers. requirements and other issues, to achieve the effect of optimizing the preparation process, reducing industrial processing costs, large-scale production, and high stacking characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

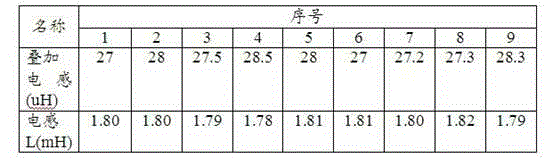

Embodiment 1

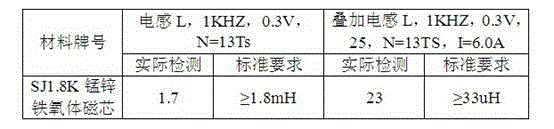

[0030] In order to improve the high stacking and high inductance of the manganese zinc ferrite core, it is necessary to increase the Fe 2 o 3 and ZnO composition content, due to Fe 2 o 3 The increase of the content will greatly improve the power loss. Based on the composition of the SJ1.8K manganese zinc ferrite core, we have determined the main composition of a material for a high stack manganese zinc ferrite core Composition: Fe 2 o 3 53.3mol%, MnO 38.2mol% and ZnO 8.5mol%; the Fe 2 o 3 The purity is above 99.5%, and the specific surface area is 4.0m 2 / g or more; the purity of the MnO is above 99.7%, and the specific surface area is 10-15m 2 / g.

[0031] First, the weight of various raw materials is calculated by converting them into weight percentages; then, the ingredients are weighed to obtain powder; the powder is pressed into a pre-fired furnace to obtain pre-fired materials, among which, The pre-fired temperature is 950°C; after the pre-fired material is vib...

Embodiment 2

[0036] In order to further improve the superimposed inductance of this manganese zinc ferrite core, under the premise that the basic composition of the core remains unchanged, Co 2 o 3 and TiO 2 , the specific method is: a material for high superimposition manganese zinc ferrite core, including the following main components calculated by mole percentage: Fe 2 o 3 53.3mol%, MnO 38.2mol% and ZnO 8.5mol%; the Fe 2 o 3 The purity is above 99.5%, and the specific surface area is 4.0m 2 / g or more; the purity of the MnO is above 99.7%, and the specific surface area is 10-15m 2 / g; further include the following additives calculated in mole percent: Co 2 o 3 0.15mol% and TiO 2 0.1mol%.

[0037] First, the weight of various raw materials is calculated by converting them into weight percentages; then, the ingredients are weighed to obtain powder; the powder is pressed into a pre-fired furnace to obtain pre-fired materials, among which, The calcining temperature is 950°C; af...

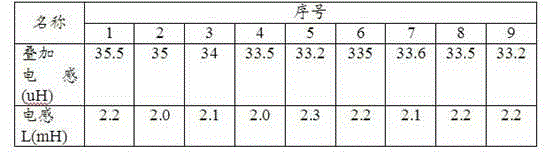

Embodiment 3

[0042] Since the Fe in this MnZn ferrite core 2 o 3 content is higher, then add a certain amount of Co 2 o 3 , resulting in an increase in the power consumption of the magnetic core. In order to change this situation, we have added a beneficial impurity to the composition of the magnetic core, CaCO 3 , SiO 2 , Nb 2 o 5 , ZrO 2 , to suppress the excessive growth of grains, improve the resistivity of the magnetic core, and improve the power consumption. The specific method is: a material for a high-layer manganese-zinc ferrite core, including the following main components calculated by molar percentage: Fe 2 o 353.3mol%, MnO 38.2mol% and ZnO 8.5mol%; the Fe 2 o 3 The purity is above 99.5%, and the specific surface area is 4.0m 2 / g or more; the purity of the MnO is above 99.7%, and the specific surface area is 10-15m 2 / g; further include the following additives calculated in mole percent: Co 2 o 3 0.15mol%, TiO 2 0.1mol%, CaCO 3 0.05mol%, SiO 2 0.005mol%, Nb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com