Saw dust soilless culture substrate and preparation method thereof

A technology of soilless culture substrate and sawdust is applied in the preparation, application, organic fertilizer and other directions of organic fertilizers, which can solve the problems of difficult fermentation and time-consuming, and achieve the effects of accelerating fermentation speed, facilitating decomposition, and reducing carbon-nitrogen ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The sawdust soilless culture substrate provided by the present invention and its preparation method are further described below.

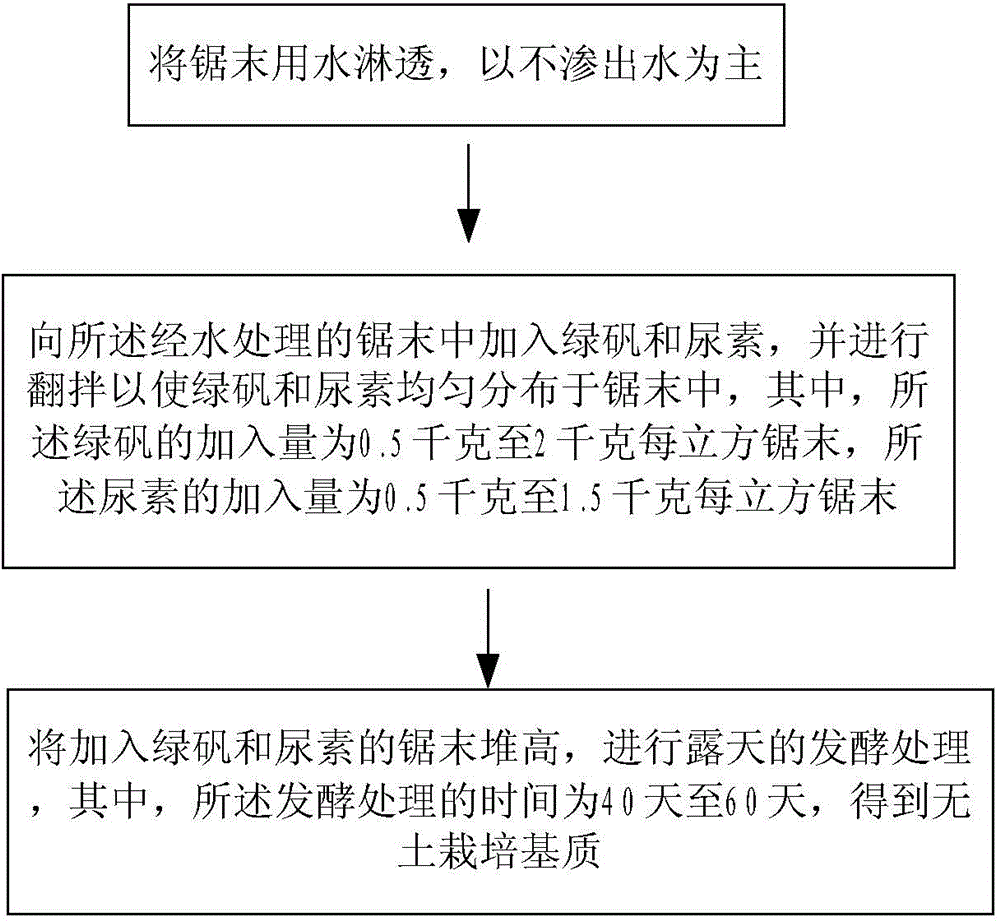

[0013] The invention provides a method for preparing a sawdust soilless culture substrate; the preparation method of the sawdust soilless cultivation substrate comprises the following steps:

[0014] (1) Add water to the sawdust, the amount of water added is to make the sawdust saturated with water, and it is advisable to just ooze water;

[0015] (2) Add vitriol and urea to the sawdust after adding water, and stir so that vitriol and urea are evenly distributed in the sawdust, wherein, the addition of vitriol is 1 kilogram per cubic meter of sawdust ~ 3 kg per cubic meter of sawdust, the amount of urea added is 0.5 kg per cubic meter of sawdust to 1.5 kg per cubic meter of sawdust; and

[0016] (3) The sawdust added with vitriol and urea is subjected to open-air fermentation treatment, wherein the time of the fermentation treatment is 40 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com