Production method of magnesium citrate anhydrous

A kind of anhydrous magnesium citrate, the technology of production method, is applied in the direction such as chemical instrument and method, separation/purification of carboxylic acid compound, carboxylate preparation, can solve the problem such as large waste of resources, unfavorable absorption, high energy consumption, reaches Facilitate absorption, reduce production cost, and be easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

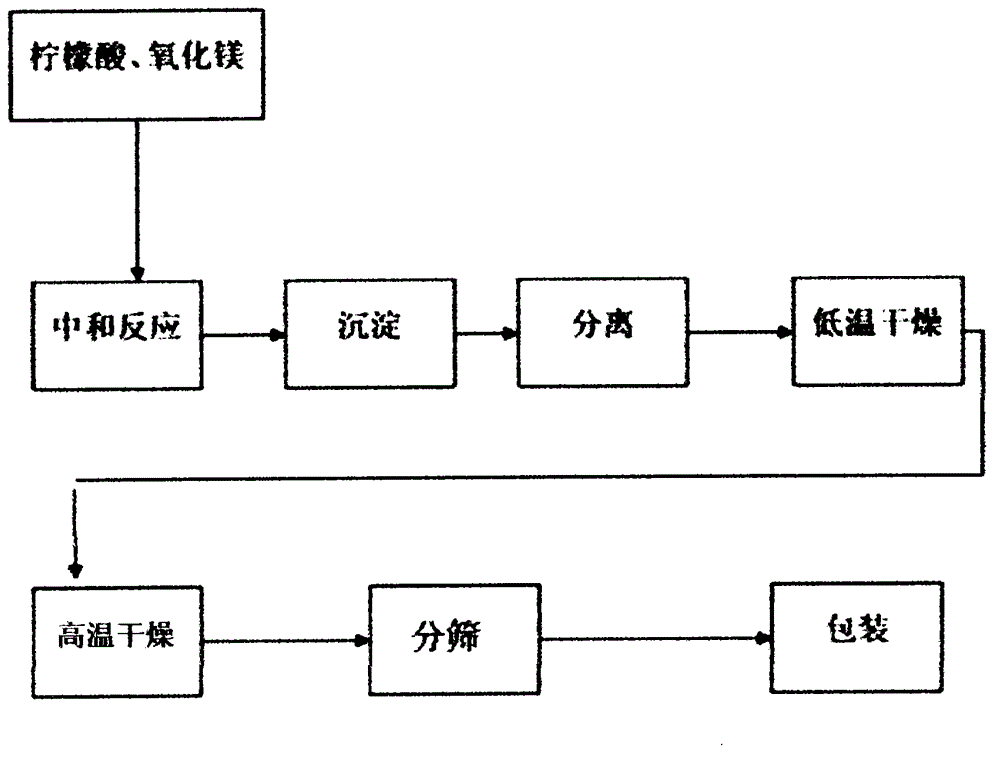

[0022] refer to figure 1 , the present embodiment adopts the following technical scheme: its production process is:

[0023] (1), inject a certain volume of purified water into the reactor, and start stirring;

[0024] (2) Add the calculated amount of clean citric acid, open the steam valve, and heat up to about 70°C to fully dissolve the citric acid;

[0025] (3), slowly add food-grade magnesium oxide calculated by chemical formula in the reactor;

[0026] (4), the reaction releases a large amount of heat, and the controlled temperature does not exceed 90°C;

[0027] (5), after feeding, make it react for 3-4 hours, produce a large amount of white precipitate, stir repeatedly;

[0028] (6), when the precipitation content reaches more than 50%, solid-liquid separation begins;

[0029] (7), after separation, dry at a low temperature of 70-80°C for about 5 hours to obtain magnesium citrate containing crystal water;

[0030] (8), raise drying temperature to 150 ℃, continue to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com