Treatment method for recycling oxadiazon etherifying salt waste

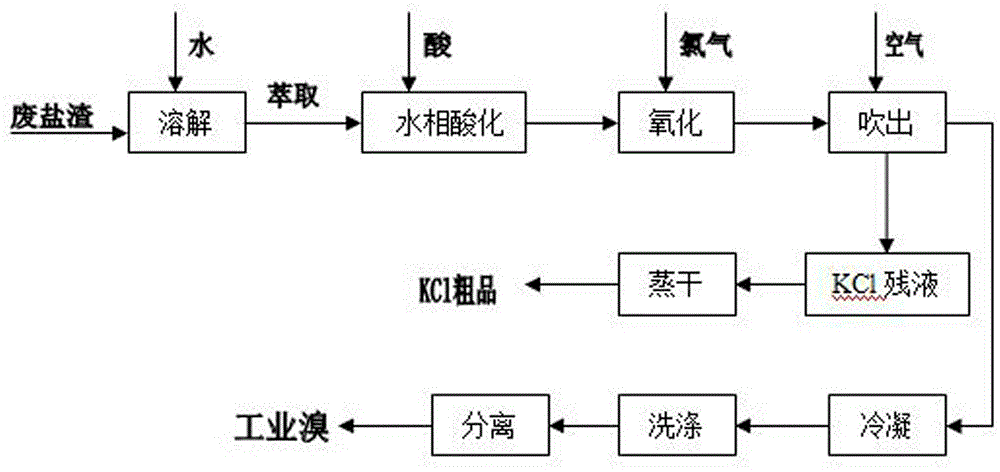

A treatment method, the technology of oxadiazon ether, is applied in the field of waste salt slag reuse treatment, and can solve the problems of no effective and reasonable industrialized treatment method, difficult direct treatment, and high treatment cost, achieve significant social benefits, solve treatment problems, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 300g of waste salt residue and add it to a 1000mL three-necked flask with electric stirring, then add 300g of water and 60g of toluene, stir for 30min to fully dissolve, pour the mixture into a 1000mL pear-shaped separating funnel and let it stand for 30min before layering , Separate the upper layer toluene extract, weighing 66.3g, for recycling, when the content of 2,4-dichloro-5-isopropoxynitrobenzene in the toluene extract reaches 30%, it will be used for the production of oxadiazone.

[0025] The separated lower aqueous solution was transferred to a 1000mL three-neck flask equipped with a thermometer, an electric stirring device and a dropping funnel, and hydrochloric acid was added dropwise to adjust the pH to 3.5. After stirring for 30 minutes to fully dissolve, the pH was re-measured to 3.5, and chlorine gas was passed. The outlet pressure of chlorine gas is controlled at 0.45 MPa ~ 0.5 MPa. When the chlorine distribution rate is 110%, the chlorine gas...

Embodiment 2

[0027] Take 300g of waste salt residue and add it to a 1000mL three-necked flask with electric stirring, then add 300g of water and 60g of toluene, stir for 30 minutes, pour the mixture into a 1000mL pear-shaped separating funnel and let it stand for 30min before layering. Separate the upper strata toluene extract, weigh 66.3g, and recycle, when the 2,4-dichloro-5-isopropoxynitrobenzene content in the toluene extract reaches 30%, it will be used for the production of oxadiazone.

[0028] The separated lower aqueous solution was transferred to a 1000mL three-neck flask equipped with a thermometer, an electric stirring device and a dropping funnel, and hydrochloric acid was added dropwise to adjust the pH to 2.5. After stirring for 30 minutes to fully dissolve, the pH was re-measured to 2.5, and chlorine gas was passed. The outlet pressure of chlorine gas is controlled at 0.45 MPa ~ 0.5 MPa. When the chlorine distribution rate is 130%, the chlorine flow is completed. At this ...

Embodiment 3

[0030] Take 300g of waste salt residue and add it to a 1000mL three-necked flask with electric stirring, then add 300g of water and 60g of toluene, stir for 30 minutes, pour the mixture into a 1000mL pear-shaped separating funnel and let it stand for 30min before layering. Separate the upper strata toluene extract, weigh 66.3g, and recycle, when the 2,4-dichloro-5-isopropoxynitrobenzene content in the toluene extract reaches 30%, it will be used for the production of oxadiazone.

[0031] The separated lower aqueous solution was transferred to a 1000mL three-necked flask equipped with a thermometer, an electric stirring device and a dropping funnel, and hydrochloric acid was added dropwise to adjust the pH to 3.0. After stirring for 30 minutes to fully dissolve, the pH was re-measured to 3.0, and chlorine gas was passed. The outlet pressure of chlorine gas is controlled at 0.45 MPa ~ 0.5 MPa. When the chlorine distribution rate is 120%, the chlorine flow is completed. At thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com