Refining method for normal-butyl isocyanate

A technology of n-butyl isocyanate and butyl isocyanate, which is applied in the field of refining n-butyl isocyanate, and can solve problems such as difficult to remove, cloudy n-butyl isocyanate, and high free acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

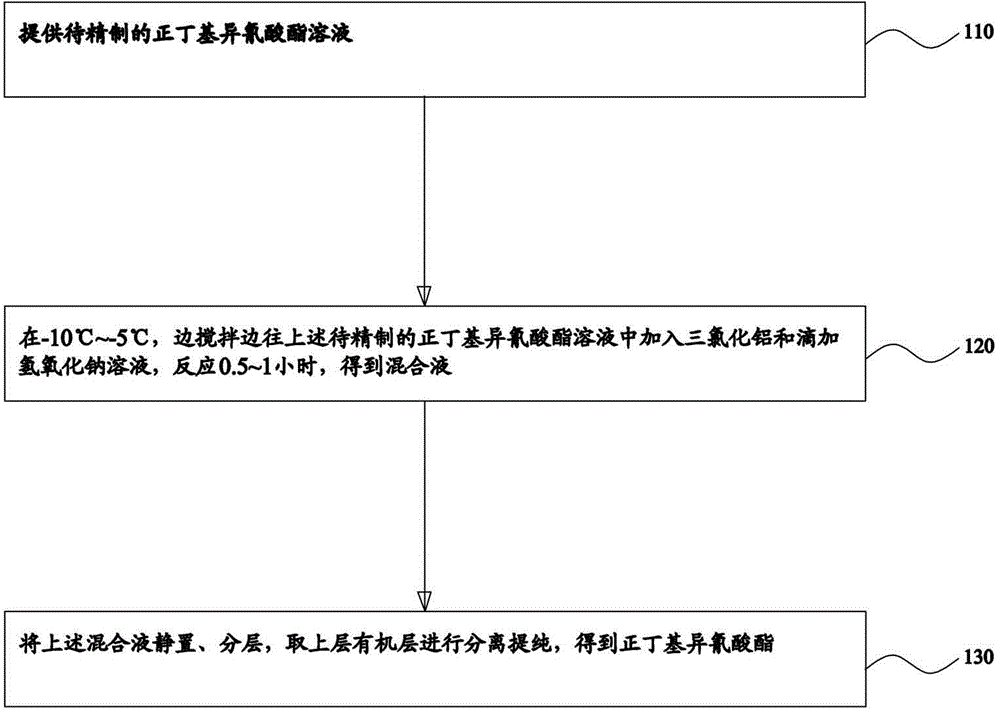

Method used

Image

Examples

Embodiment 1

[0045] Provide 500L of n-butyl isocyanate solution to be refined. After analysis, the mass content of n-butyl isocyanate is 99.1%, the mass content of free acid is 0.69%, and there are a large amount of white flocs inside.

[0046] At -8°C, add aluminum trichloride and dropwise 0.2mol / L sodium hydroxide solution to the n-butyl isocyanate solution to be refined while stirring, and react for 1 hour to obtain a mixed solution, in which n-butyl isocyanate to be refined The mass ratio of base isocyanate solution, aluminum trichloride and sodium hydroxide solution is 1:0.05:5.5.

[0047] The above mixed solution was left to stand for 60 minutes, the upper organic layer was taken for vacuum distillation, and fractions were collected to obtain a 480L sample. After analysis, the mass content of n-butyl isocyanate in the sample was 99.63%, the mass content of free acid was 0.09%, and the appearance was clear and transparent; after the sample was placed for 7 days, the mass content of n-...

Embodiment 2

[0049] Provide 1000L of n-butyl isocyanate solution to be refined. After analysis, the mass content of n-butyl isocyanate is 99.21%, the mass content of free acid is 0.75%, and there are a large amount of white flocs inside.

[0050] At -10°C, add aluminum trichloride and dropwise 0.23mol / L sodium hydroxide solution to the n-butyl isocyanate solution to be refined while stirring, and react for 1 hour to obtain a mixed solution, in which the n-butyl isocyanate to be refined The mass ratio of base isocyanate solution, aluminum trichloride and sodium hydroxide solution is 1:0.05:5.

[0051]The above mixed solution was left to stand for 30 minutes, the upper organic layer was taken for vacuum distillation, and fractions were collected to obtain a 985L sample. After analysis, the mass content of n-butyl isocyanate in the sample was 99.7%, the mass content of free acid was 0.06%, and the appearance was clear and transparent; after the sample was placed for 14 days, the mass content ...

Embodiment 3

[0053] Provide 1500L of n-butyl isocyanate solution to be refined. After analysis, the mass content of n-butyl isocyanate is 99.23%, the mass content of free acid is 0.72%, and there are a large amount of white flocs inside.

[0054] At -7°C, add aluminum trichloride and dropwise 0.25mol / L sodium hydroxide solution to the n-butyl isocyanate solution to be refined while stirring, and react for 1 hour to obtain a mixed solution, in which n-butyl isocyanate to be refined The mass ratio of base isocyanate solution, aluminum trichloride and sodium hydroxide solution is 1:0.05:5.5.

[0055] The above mixed solution was left to stand for 45 minutes, and the upper organic layer was taken for vacuum distillation, and fractions were collected to obtain a 1480L sample. After analysis, the mass content of n-butyl isocyanate in the sample is 99.78%, the mass content of free acid is 0.04%, and the appearance is clear and transparent; after standing for 28 days, the mass content of n-butyl i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com