A kind of preparation method of high-content Armillaria chrysanthemum polysaccharide

A yellow-green Armillaria, high-content technology is applied in the field of preparation of high-content polysaccharides, can solve the problems of high energy consumption, unspecified polysaccharide content and polysaccharide extraction rate, backwardness, etc., and achieves simple preparation process, no toxic side effects, less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

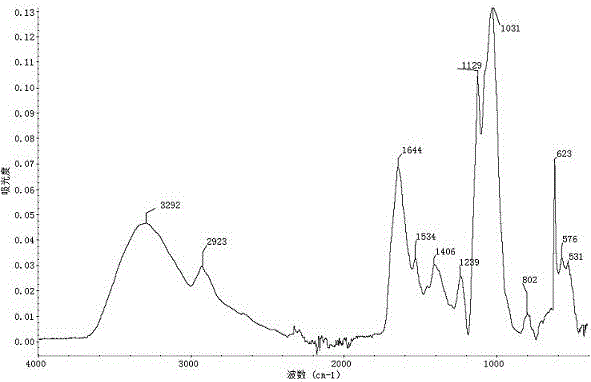

Image

Examples

Embodiment 1

[0033] Example 1 A method for preparing a high-content Armillaria chrysanthemum polysaccharide, comprising the following steps:

[0034] (1) After drying the fresh Armillaria chrysanthemum at 30° C. to a constant weight, the dried Armillaria chrysanthemum is obtained.

[0035] (2) The dried Armillaria chrysanthemum was pulverized into a dry powder with a particle size of 10 um with a superfine pulverizer.

[0036] (3) Add water to the dry powder at a liquid-to-solid ratio of 10ml:1g, and then use microwave extraction method to extract for 15min under the conditions of microwave power of 50W and extraction temperature of 40°C to obtain the extract.

[0037] (4) The extract is concentrated under reduced pressure at a vacuum degree of 0.01 MPa and a temperature of 50° C., and then dehydrated to an extract to obtain a concentrated solution.

[0038] (5) Add 3 times the volume of absolute ethanol to the concentrated solution for precipitation, centrifuge after standing still for 2...

Embodiment 2

[0040] Example 2 A method for preparing high-content Armillaria chrysanthemum polysaccharides, comprising the following steps:

[0041] (1) After drying the fresh Armillaria chrysanthemum at 70° C. to a constant weight, the dried Armillaria chrysanthemum is obtained.

[0042] (2) The dried Armillaria chrysanthemum was pulverized into a dry powder with a particle size of 200 um with a superfine pulverizer.

[0043] (3) Add water to the dry powder at a liquid-to-material ratio of 100ml:1g, and then use microwave extraction method to extract for 60 minutes under the conditions of microwave power 1000W and extraction temperature 90°C to obtain the extract.

[0044] (4) The extract is concentrated and dehydrated under reduced pressure under the conditions of a vacuum of 0.09MPa and a temperature of 90°C until it is in the form of an extract to obtain a concentrated solution.

[0045] (5) Add 6 times the volume of absolute ethanol to the concentrated solution for precipitation, cen...

Embodiment 3

[0047] Example 3 A method for preparing a high-content Armillaria chrysanthemum polysaccharide, comprising the following steps:

[0048] (1) After drying the fresh Armillaria chrysanthemum at 40° C. to a constant weight, the dried Armillaria chrysanthemum is obtained.

[0049] (2) The dried Armillaria chrysanthemum was pulverized into a dry powder with a particle size of 100 um with a superfine pulverizer.

[0050] (3) Add water to the dry powder at a liquid-to-solid ratio of 50ml:1g, and then use microwave extraction method to extract for 30min under the conditions of microwave power of 500W and extraction temperature of 60°C to obtain the extract.

[0051] (4) The extract is concentrated by a nanofiltration membrane and then dehydrated into an extract to obtain a concentrate.

[0052] Among them: the membrane separation operating pressure is 20 MPa.

[0053] (5) Add 4 times the volume of absolute ethanol to the concentrated solution for precipitation, centrifuge after stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com