Method for preparing environment-friendly low-smoke flame-retardant powdered butadiene styrene rubber

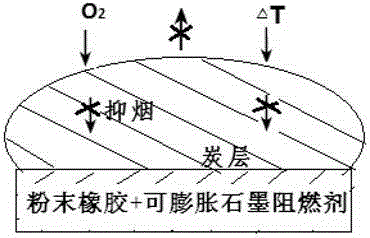

A technology of powdered styrene-butadiene rubber and styrene-butadiene latex, which is applied in the preparation of high flame-retardant powdered styrene-butadiene rubber and low-smoke fields. It can solve the problems of uneven dispersion, achieve improved compatibility, ensure particle size, and good flame-retardant effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

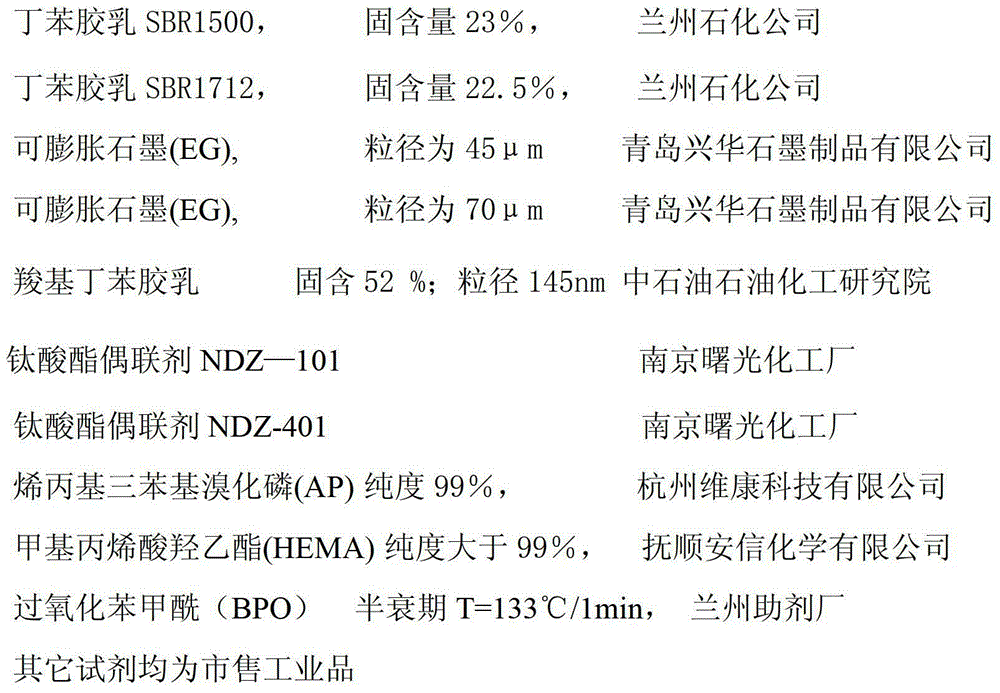

[0040] (一)功能化可膨胀石墨:将2份钛酸酯偶联剂NDZ-101和60份水、6份乙醇加入到聚合釜中搅拌混合均匀,用质量浓度为0.05%草酸溶液调节体系pH值为4,然后加入100份可膨胀石墨,搅拌混合20min;再加入6份羧基丁苯胶乳搅拌混合50min;脱水、干燥、研磨得到功能化可膨胀石墨a。

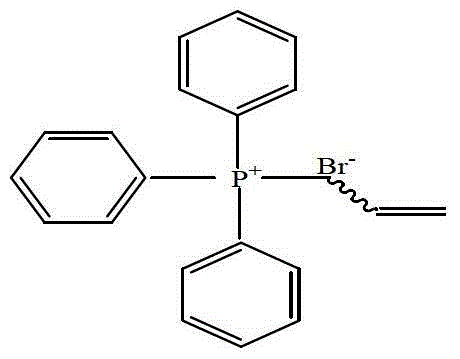

[0041] (二)阻燃型接枝胶乳的制备:在聚合釜中首先加入150份去离子水、然后依次加入100份丁苯胶乳SBR1500、2.5份十二烷基苯磺酸钠、0.3份十二碳硫醇,用氮气置换后,紧接着先加入6份的烯丙基三苯基溴化磷接枝单体,搅拌、加热,待聚合釜温度达到50℃时加入0.15份BPO,反应8h后,然后在在加入2份的HEMA和0.05份BPO,继续反应3h后,加入0.2二乙基羟胺,制得阻燃型接枝丁苯胶乳a。取样分析:测得SBR-g-HEMA的接枝率为0.9%。

[0042] (三)阻燃粉末丁苯橡胶的制备:取100份阻燃型接枝胶乳a和1.5份功能化可膨胀石墨a、70份水加入到凝聚釜里搅拌混合25min,然后升温至50℃时,依次加入3份油酸钾、2.5份氯化镁,用氢氧化钠调节体系pH值为9.3时进行凝聚,依次加入3份油酸钾、2.5份氯化镁,用氢氧化钠调节体系pH值为9.3时进行凝聚,升温至80℃时搅拌25min进行熟化,然后经洗涤、脱水、干燥得到低烟、高阻燃粉末丁苯橡胶产品。取样分析:制成标准试样,经测试性能见表1。

Embodiment 2

[0044] (一)功能化可膨胀石墨的制备:同实施例1。

[0045] (二)阻燃型接枝胶乳的制备:同实施例1。

[0046] (三)阻燃粉末丁苯橡胶的制备:取100份阻燃型接枝胶乳a和3份功能化可膨胀石墨a、70份水加入到凝聚釜里搅拌混合25min,然后升温至50℃时,依次加入3份油酸钾、2.5份氯化镁,用氢氧化钠调节体系pH值为9.3时进行凝聚,依次加入3份油酸钾、2.5份氯化镁,用氢氧化钠调节体系pH值为9.3时进行凝聚,升温至80℃时搅拌25min进行熟化,然后经洗涤、脱水、干燥得到低烟、高阻燃粉末丁苯橡胶产品。取样分析:制成标准试样,经测试性能见表1。

Embodiment 3

[0048] (一)功能化可膨胀石墨的制备:同实施例1。

[0049] (二)阻燃型接枝胶乳的制备:同实施例1。

[0050] (三)阻燃型粉末丁苯橡胶的制备:取100份阻燃型接枝胶乳a和4份功能化可膨胀石墨a、70份水加入到凝聚釜里搅拌混合25min,然后升温至50℃时,依次加入3份油酸钾、2.5份氯化镁,用氢氧化钠调节体系pH值为9.3时进行凝聚,依次加入3份油酸钾、2.5份氯化镁,用氢氧化钠调节体系pH值为9.3时进行凝聚,升温至80℃时搅拌25min进行熟化,然后经洗涤、脱水、干燥得到低烟、高阻燃粉末丁苯橡胶产品。取样分析:制成标准试样,经测试性能见表1。

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com