Surface modification method of oil-soluble upconversion luminescent nanometer material

A fluorescent nanomaterial and surface modification technology, which is applied in the field of surface modification to improve the water solubility of oil-soluble rare earth up-conversion fluorescent nanomaterials, can solve the problems of affecting the fluorescence of materials, instability, generation of impurity materials, etc., and achieves low cytotoxicity and good cytotoxicity. Water-soluble, low biocompatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In this embodiment, the surface modification of oil-soluble up-conversion fluorescent nanomaterials is carried out according to the following steps:

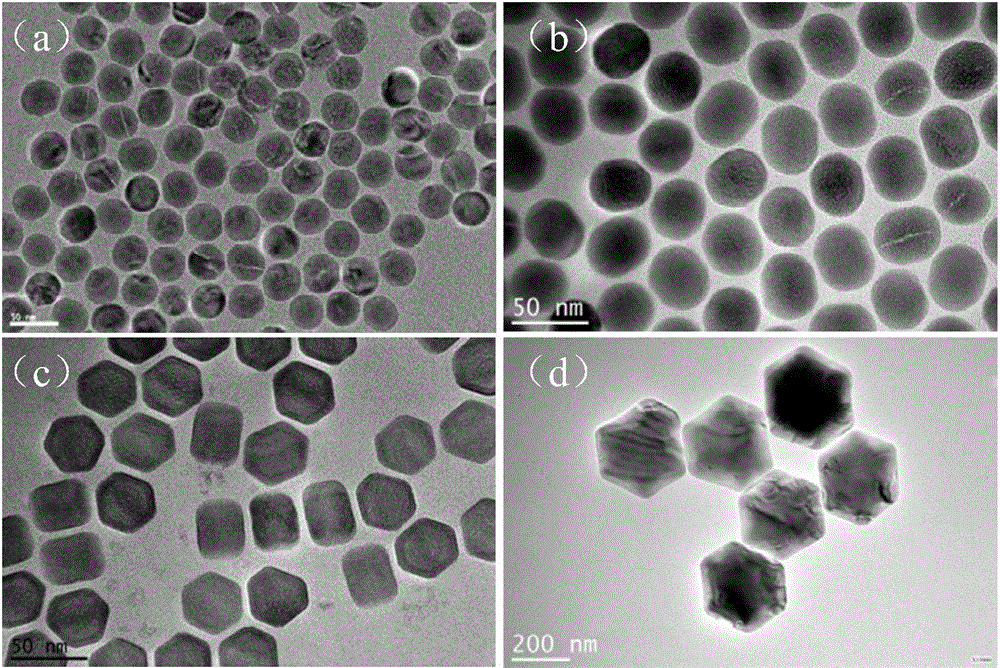

[0057] a. Weigh 80mg NaYF 4 :Yb,Er,NdNaYF 4 : Nd (40nm) oil-soluble up-conversion fluorescent nanomaterial with core-shell structure is placed in a flask, and 3 mL of chloroform is added to disperse evenly to obtain solution A;

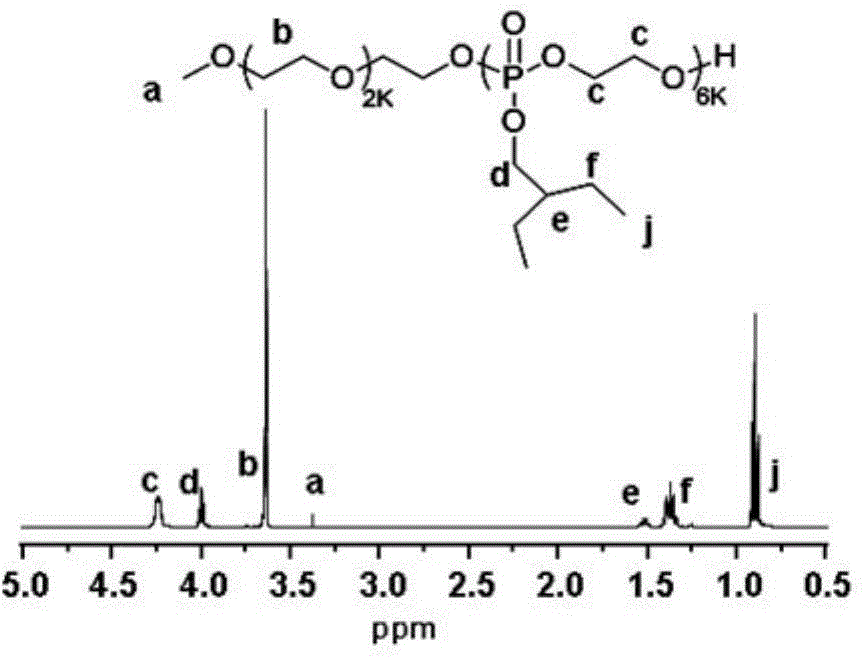

[0058] b. Add 10 mg mPEG to Solution A 2K -b-PEBEP 6K , stirred for 0.5h to obtain reaction solution B;

[0059] c. Add 40mL of deionized water to the reaction solution B, and stir for 0.5h to obtain the reaction solution C;

[0060] d. At 20°C, remove the chloroform in the reaction solution C to obtain the reaction solution D;

[0061] e. The reaction solution D was centrifuged at 10000 rpm for 10 min, and the obtained precipitate was dried, that is, the surface modification of the oil-soluble up-conversion fluorescent nanomaterial was completed, and the water-soluble up-conversion fluoresc...

Embodiment 2

[0067] In this embodiment, the surface modification of oily upconversion nanoparticles is carried out according to the following steps:

[0068] a. Weigh 169mg NaYF 4 : Yb, Er (18nm) oil-soluble up-conversion nanoparticles in a flask, add 10mL of chloroform, and disperse evenly to obtain solution A;

[0069] b. Add 10 mg mPEG to Solution A 2K -b-PEBEP 6K , stirred for 1h to obtain reaction solution B;

[0070] c. Add 100 mL of deionized water to the reaction solution B, and stir for 2 hours to obtain the reaction solution C;

[0071] d. At 40°C, remove the chloroform in the reaction solution C to obtain the reaction solution D;

[0072] e. The reaction solution D was centrifuged at 14600 rpm for 20 minutes, and the obtained precipitate was dried, that is, the surface modification of the oil-soluble up-conversion fluorescent nanomaterial was completed, and the water-soluble up-conversion fluorescent nanomaterial was obtained.

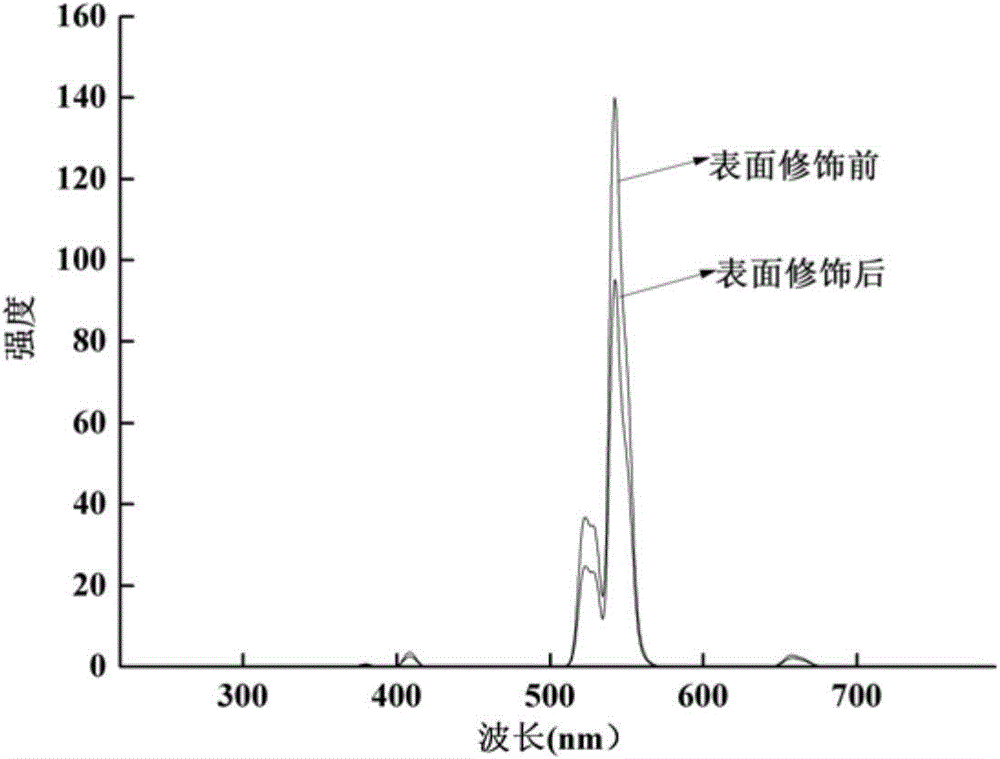

[0073] Characterized by a fluorescence spectr...

Embodiment 3

[0075] In this embodiment, the surface modification of oily upconversion nanoparticles is carried out according to the following steps:

[0076] a. Weigh 60mg NaYF 4 : Yb, Er, Nd (34nm) oil-soluble up-conversion nanoparticles in a flask, add 4mL cyclohexane, uniformly dispersed, to obtain solution A;

[0077] b. Add 10 mg mPEG to Solution A 2K -b-PEBEP 6K , stirred for 1h to obtain reaction solution B;

[0078] c. Add 60 mL of deionized water to the reaction solution B, and stir for 2 hours to obtain the reaction solution C;

[0079] d. At 40°C, remove the cyclohexane in the reaction solution C to obtain the reaction solution D;

[0080] e. The reaction solution D was centrifuged at 12000 rpm for 10 min, and the obtained precipitate was dried, that is, the surface modification of the oil-soluble up-conversion fluorescent nanomaterial was completed, and the water-soluble up-conversion fluorescent nanomaterial was obtained.

[0081] Characterized by the fluorescence spectro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com