Paraffin-based transformer oil and preparation method thereof

A transformer oil and paraffin-based technology, which is applied in the petroleum industry, base materials, lubricating compositions, etc., can solve problems such as cost and performance can not be balanced, and achieve the effect of excellent comprehensive performance, excellent anti-oxidation performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

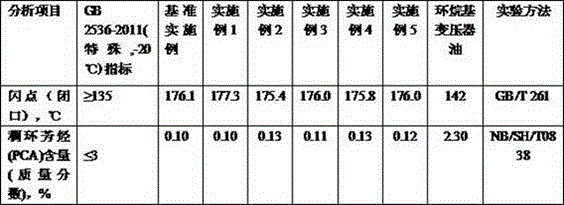

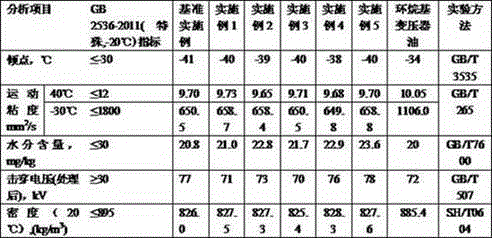

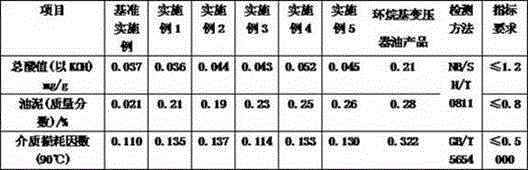

Examples

Embodiment 1

[0032] Select second-line wax oil, third-line wax oil and coker wax oil as mixed raw materials, alkylbenzene as aromatic compound, and T501 as oxidant to prepare transformer oil. The specific steps are as follows:

[0033] The first step is the preparation of Group II base oil. The second-line wax oil, the third-line wax oil and the coker wax oil are used as mixed raw materials. After hydrocracking reaction, hydroisomerization dewaxing reaction, hydrogenation post-refining reaction, and then After normal pressure fractionation and vacuum fractionation, the Group II base oil with aromatic carbon CA content less than 0.5% is obtained;

[0034] In order to obtain a Group II base oil with an aromatic carbon CA content of less than 0.5%, the specific process conditions for the hydrocracking reaction, hydroisomerization dewaxing reaction, and post-hydrogenation refining reaction are as follows:

[0035] The process conditions of the hydrocracking reaction are as follows: the pressur...

Embodiment 2

[0042] Select second-line wax oil, third-line wax oil and coker wax oil as mixed raw material oil, alkylnaphthalene as aromatic compound, and T501 as oxidant to prepare transformer oil. The specific steps are as follows:

[0043] The first step is the preparation of Group II base oil. The second-line wax oil, the third-line wax oil and the coker wax oil are used as mixed raw materials. After hydrocracking reaction, hydroisomerization dewaxing reaction, hydrogenation post-refining reaction, and then After normal pressure fractionation and vacuum fractionation, the Group II base oil with aromatic carbon CA content less than 0.5% is obtained;

[0044] In order to obtain a Group II base oil with an aromatic carbon CA content of less than 0.5%, the specific process conditions for the hydrocracking reaction, hydroisomerization dewaxing reaction, and post-hydrogenation refining reaction are as follows:

[0045] The process conditions of the hydrocracking reaction are as follows: the ...

Embodiment 3

[0052] Select second-line wax oil, third-line wax oil and coker wax oil as mixed raw material oil, use naphthalene as aromatic compound, and T501 as oxidant to prepare transformer oil. The specific steps are as follows:

[0053] The first step is the preparation of Group II base oil. The second-line wax oil, the third-line wax oil and the coker wax oil are used as mixed raw materials. After hydrocracking reaction, hydroisomerization dewaxing reaction, hydrogenation post-refining reaction, and then After normal pressure fractionation and vacuum fractionation, the Group II base oil with aromatic carbon CA content less than 0.5% is obtained;

[0054] In order to obtain a Group II base oil with an aromatic carbon CA content of less than 0.5%, the specific process conditions for the hydrocracking reaction, hydroisomerization dewaxing reaction, and post-hydrogenation refining reaction are as follows:

[0055] The process conditions of the hydrocracking reaction are: the pressure is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com