Method for separating lead and antimony of jamesonite concentrate by virtue of vacuum treatment

A brittle sulfur-lead-antimony ore and vacuum treatment technology, which is applied in the field of non-ferrous metal smelting, can solve the problems of environmental pollution, excessive material returns, and long process flow, so as to avoid the production of lead-antimony alloys, reduce production costs, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

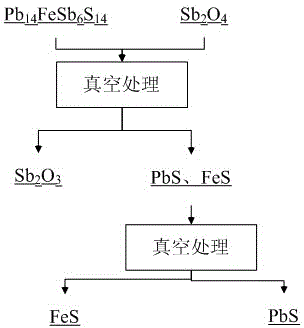

[0031] Embodiment 1: as figure 1 Shown, the method for vacuum treatment of brittle pyroprobite to separate lead and antimony, its concrete steps are as follows:

[0032] (1) Combine the beneficiated brittle lead antimonite and yellow antimonite (Pb 4 FeSb 6 S 14 with Sb 2 o 4 Molar ratio 1: 1.7) mixing;

[0033] (2) Place the mixed material obtained in step (1) in a vacuum furnace, vacuum distill for 2 hours under the conditions of controlling the residual pressure in the furnace to 5Pa and the distillation temperature to 550°C, and then cool it down. When the temperature drops below 100°C, close the Vacuum system, take out material after cooling to obtain volatile Sb 2 o 3 Product and residue PbS and FeS;

[0034] (3) Put the residue PbS and FeS obtained in step (2) in a vacuum furnace, vacuum distill for 2 hours under the condition of controlling the residual pressure in the furnace to be 10Pa, and the distillation temperature is 1000°C, and then cool down. When the ...

Embodiment 2

[0036] Embodiment 2: as figure 1 Shown, the method for vacuum treatment of brittle pyroprobite to separate lead and antimony, its concrete steps are as follows:

[0037] (1) Combine the brittle pyroprobite and pure Sb after beneficiation 2 o 4 (Pb 4 FeSb 6 S 14 with Sb 2 o 4 Molar ratio 1: 1.6) mixing;

[0038] (2) Place the mixed material obtained in step (1) in a vacuum furnace, vacuum distill for 1.5 hours under the conditions of controlling the residual pressure in the furnace to 10Pa and the distillation temperature to 600°C, and then cool it down. When the temperature drops below 100°C, Close the vacuum system, take the material after cooling, and obtain the volatile Sb 2 o 3 Product and residue PbS and FeS;

[0039] (3) Put the residues PbS and FeS obtained in step (2) in a vacuum furnace, vacuum distill for 1 hour under the conditions of controlling the residual pressure in the furnace to be 15Pa and the distillation temperature to be 1200°C, and then cool do...

Embodiment 3

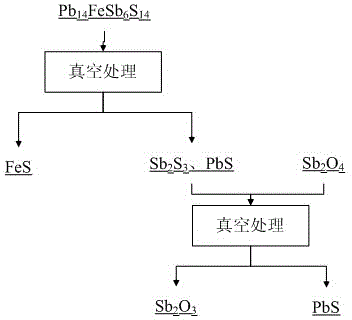

[0041] Embodiment 3: the method for separating lead and antimony from this vacuum treatment brittle pyroprobite ore, its specific steps are as follows:

[0042] (1) Combine the brittle pyroprobite and pure Sb after beneficiation 2 o 4 (Pb 4 FeSb 6 S 14 with Sb 2 o 4 molar ratio 1:1.5) mixing;

[0043] (2) Place the mixed material obtained in step (1) in a vacuum furnace, vacuum distill for 1 hour under the conditions of controlling the residual pressure in the furnace to 20Pa and the distillation temperature to 580°C, and then cool it down. When the temperature drops below 100°C, close the Vacuum system, take out material after cooling to obtain volatile Sb 2 o 3 Product and residue PbS and FeS;

[0044] (3) Put the residue PbS and FeS obtained in step (2) in a vacuum furnace, vacuum distill for 0.5h under the conditions of controlling the residual pressure in the furnace to 5Pa and the distillation temperature to 1400°C, and then cool it down. When the temperature dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com