A niobium-molybdenum composite microalloyed high-strength bainite steel and its preparation method

A micro-alloying, bainitic steel technology, applied in the field of bainitic steel, can solve the problems of unfavorable industrial production, insufficient tensile strength, difficult plasticity and toughness, etc., achieve good strength and plasticity, and improve strength and toughness. , good matching of strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

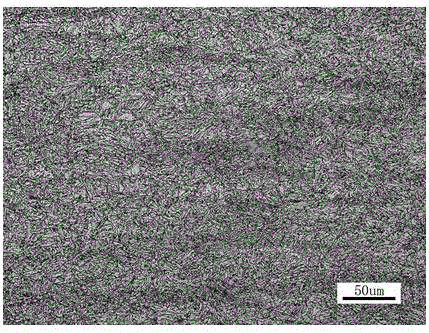

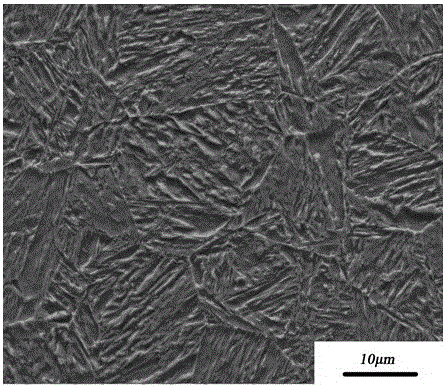

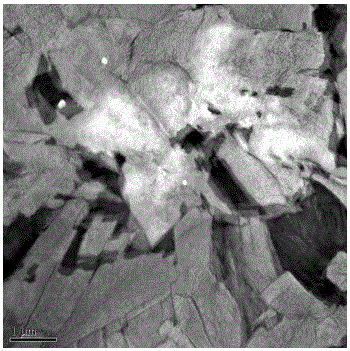

Image

Examples

Embodiment 1

[0024] A niobium-molybdenum composite microalloyed high-strength bainite steel and a preparation method thereof. The preparation method of this embodiment is as follows: the billet is rolled by a hot rolling mill, the starting temperature of the rough rolling is 1150~1160°C, the starting temperature of the finishing rolling is 950~960°C, and the finishing rolling temperature is 900~910°C. ℃; then cool at a rate of 30~50℃ / s to 420~450℃, then air cool to 330~340℃, keep warm at 330~340℃ for 30~45min, and then water cool to room temperature.

[0025] The chemical composition and content of the slab are: C is 0.19~0.21wt%, Si is 1.43~1.47wt%, Mn is 1.94~1.98wt%, Nb is 0.025~0.026wt%, Mo is 0.142~0.148wt% %, P<0.008wt%, S<0.002wt%, N<0.004wt%, the rest is Fe and unavoidable impurities.

[0026] The tensile strength of the niobium-molybdenum composite microalloyed high-strength bainite steel prepared in this example is 1200-1250 MPa, and the elongation is 20.0-22.7%.

Embodiment 2

[0028] A niobium-molybdenum composite microalloyed high-strength bainite steel and a preparation method thereof. The preparation method of this embodiment is: rolling the cast slab by a hot rolling mill, the starting temperature of the rough rolling is 1160~1170°C, the starting temperature of the finishing rolling is 960~970°C, and the finishing rolling temperature is 910~920°C. ℃; then cool at a rate of 30~50℃ / s to 420~450℃, then air cool to 340~350℃, keep warm at 340~350℃ for 30~45min, and then water cool to room temperature.

[0029]The chemical composition and content of the billet are: C is 0.20~0.22wt%, Si is 1.46~1.49wt%, Mn is 1.97~2.01wt%, Nb is 0.025~0.026wt%, Mo is 0.147~0.149wt% %, P<0.008wt%, S<0.002wt%, N<0.004wt%, the rest is Fe and unavoidable impurities.

[0030] The tensile strength of the niobium-molybdenum composite microalloyed high-strength bainite steel prepared in this example is 1180-1230 MPa, and the elongation is 21.6-23.5%.

Embodiment 3

[0032] A niobium-molybdenum composite microalloyed high-strength bainite steel and a preparation method thereof. The preparation method of this embodiment is as follows: rolling the slab with a hot rolling mill, the starting temperature of the rough rolling is 1170~1180°C, the starting temperature of the finish rolling is 970~980°C, and the finish rolling temperature is 920~930°C. ℃; then cool at a rate of 30~50℃ / s to 420~450℃, then air cool to 350~360℃, keep warm at 350~360℃ for 30~45min, and then water cool to room temperature.

[0033] The chemical composition and content of the billet are: C is 0.21~0.224wt%, Si is 1.48~1.50wt%, Mn is 1.99~2.05wt%, Nb is 0.026~0.027wt%, Mo is 0.148~0.15wt% %, P<0.008wt%, S<0.002wt%, N<0.004wt%, the rest is Fe and unavoidable impurities.

[0034] The tensile strength of the niobium-molybdenum composite microalloyed high-strength bainite steel prepared in this example is 1160-1210 MPa, and the elongation is 22.3-23.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com