multilayer cardboard

A multi-layer cardboard and cardboard technology, applied in papermaking, paper/cardboard layered products, paper, etc., can solve problems such as insufficient supply of softwood pulp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

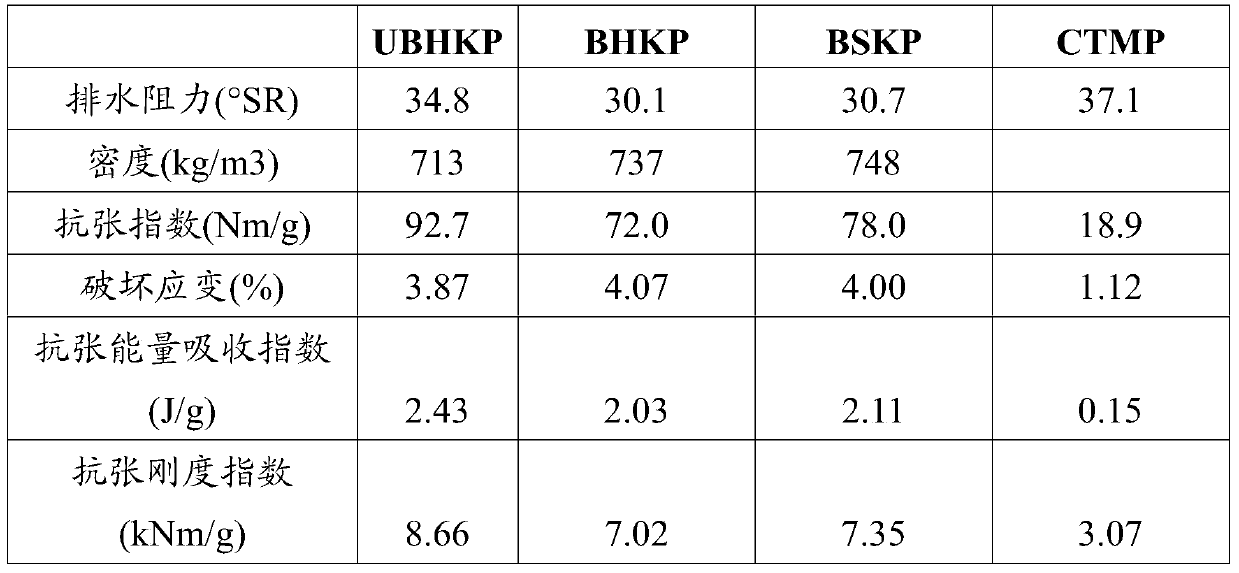

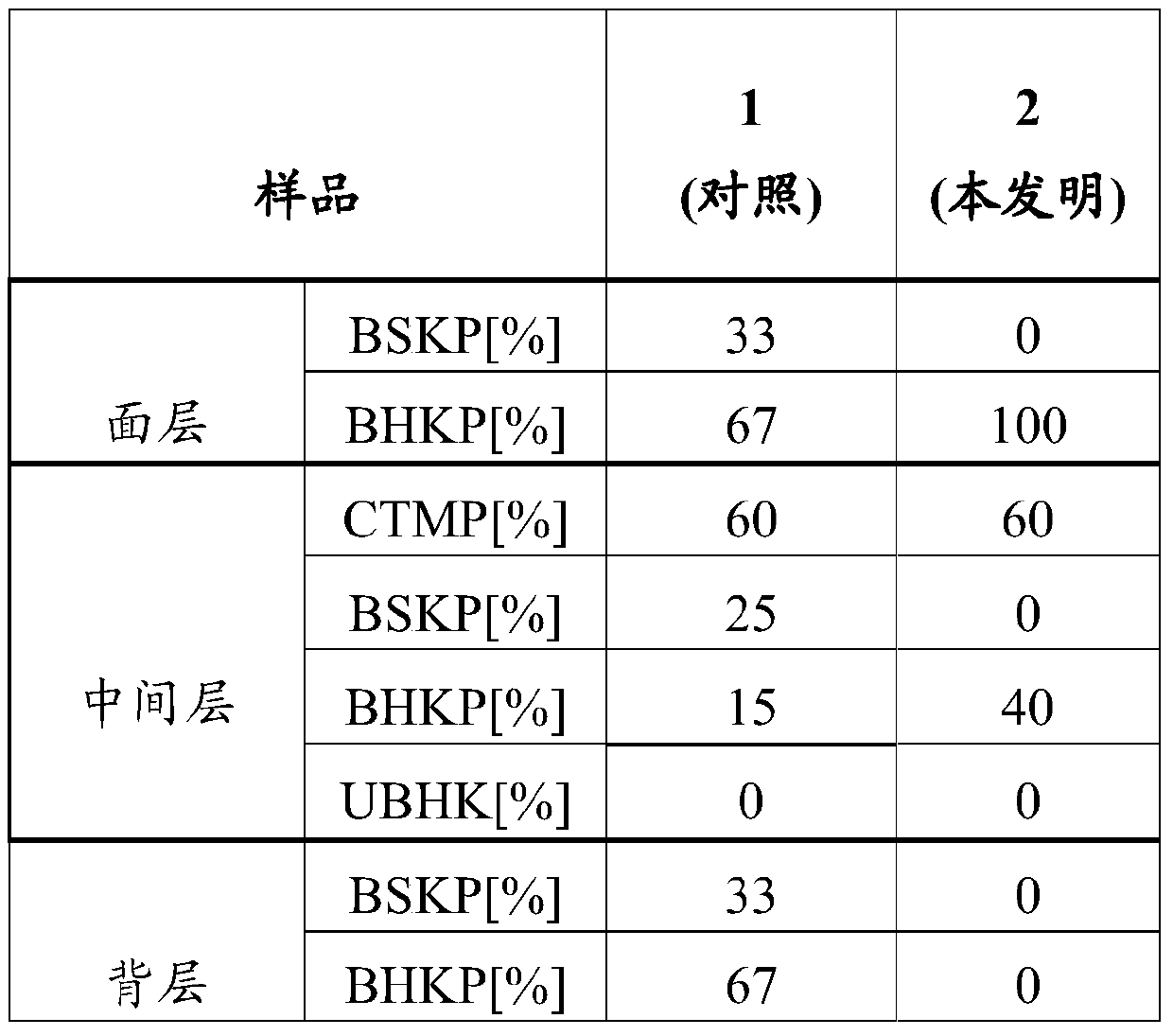

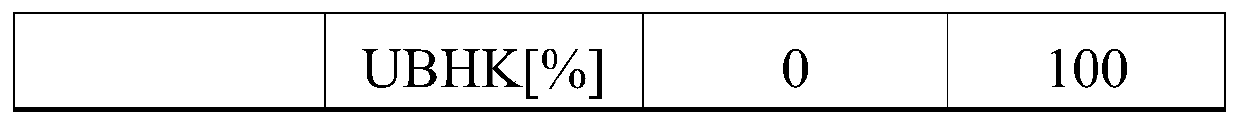

[0070] In order to evaluate the high quality paperboard of the present invention, a test series was carried out in which a paperboard with a back ply comprising 100% unbleached hardwood pulp was compared to a conventional paperboard comprising softwood pulp. In the tests, both paperboards were of three-ply construction, with a face and a back and middle ply.

[0071] The strength properties, surface properties and optical properties of each paperboard were studied. All tests were performed according to the methods and standards indicated above, all analyzes were performed after conditioning at 23°C, 50% RH according to available standards.

[0072] cardboard sample

[0073] Two three-ply paperboards, each having a top and back ply and a middle ply, were produced using an Automatic Dynamic Sheet Former (Formette Dynamique). The basis weight of the paperboard was about 185 gsm with a weight distribution of: top ply-middle ply-back ply = 40-110-35 gsm.

[0074] The properties ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com