Method for reinforcing and treating liquefied sandy soil foundation

A technology of sand foundation and reinforcement liquid, which is applied in foundation treatment, utilizes microbial mineralization to reinforce and treat liquefied sand foundation field, can solve the problems of high foundation treatment cost, limited impact depth of dynamic compaction method, and large environmental impact, and achieves the impact of Small size, good fluidity, and the effect of improving liquefaction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

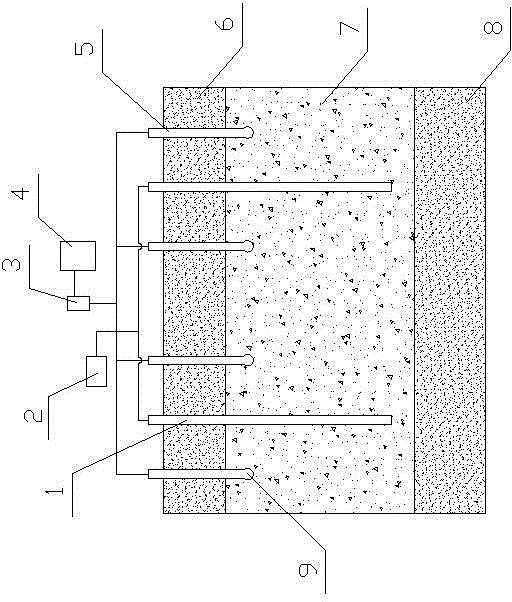

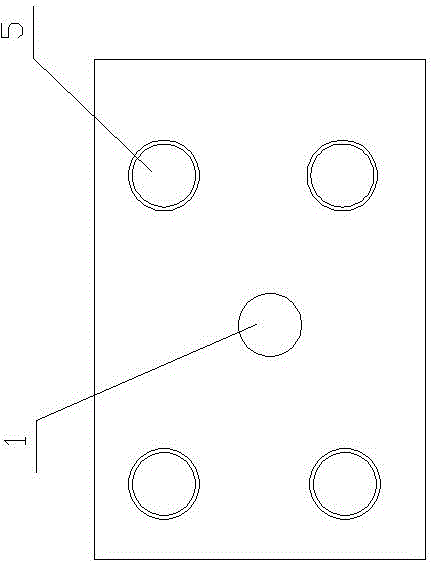

[0033] Embodiment 1, a kind of method for reinforcing and controlling liquefied sand foundation, such as figure 1 with figure 2 As shown, on the sandy soil layer 7 to be reinforced on the sandy soil foundation, several drainage pipes 1 are embedded by drilling, and several liquid inlet pipes 5 are buried around each drainage pipe 1. The several liquid inlet pipes 5 arranged like figure 2 The rectangle shown. The drain pipe 1 and the liquid inlet pipe 5 are both PVC pipes with an inner diameter of 5 cm and a wall thickness of 5 mm. The bottom end of each liquid inlet pipe 5 is equipped with a spherical diffusion head 9 with a diameter of 9 cm. The spherical diffusion head 9 is evenly provided with some liquid outlet holes, and the diameter of the liquid outlet holes is 5 mm. The wall of the drainage pipe 1 in the sand layer 7 to be reinforced is provided with a number of liquid inlet holes, and the number of liquid outlet holes of the drainage pipe 1 gradually increases f...

Embodiment 2

[0037] Embodiment 2, the method as described in embodiment 1, described reinforcement liquid is with water as solvent and contains calcium ion, urea and urea bacteria; Wherein: the mass concentration of urea is 50g / L, the carbon atom in calcium ion and urea The quantity ratio is 1:1, and the concentration of urea bacteria is 10 8 ~10 10 pcs / L; and the pH of the reinforcement solution is 5.5~6.5.

Embodiment 3

[0038] Embodiment 3, the method as described in embodiment 2, described calcium ion comes from soluble calcium salt, comprises calcium chloride or calcium nitrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com