Rural low-rise assembled damping building structure system

A prefabricated, low-rise technology, applied in the direction of building components, building structures, buildings, etc., can solve problems such as prone to collapse, achieve the effect of reducing labor intensity, high labor intensity, and easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

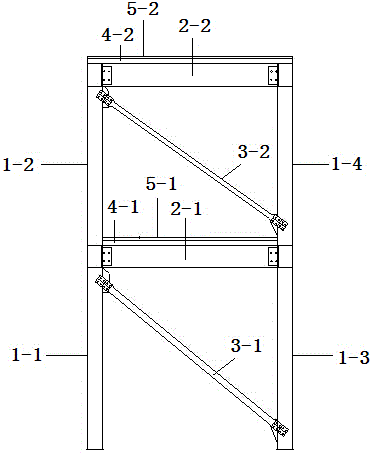

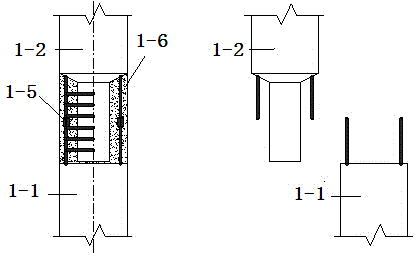

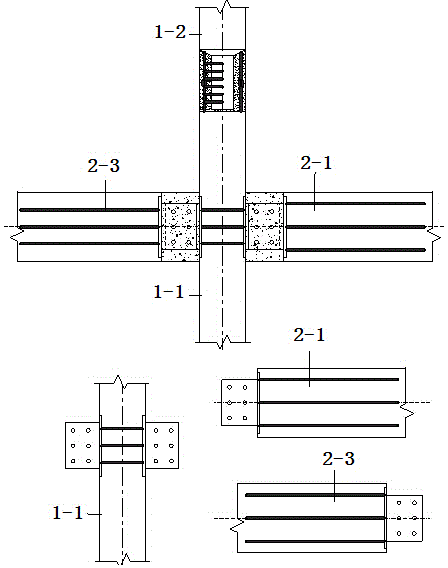

[0028] The present invention is further illustrated below by means of embodiments in conjunction with the accompanying drawings.

[0029] For a rural building, the vertical load determines the section of the frame beam and frame column, and the horizontal load determines the section of the shock-absorbing energy-dissipating support. During construction, the frame beams and frame columns are connected in the form of hinged bolts. Frame columns, frame beams, wall panels, prefabricated floors, and shock-absorbing energy-dissipating supports are processed in the processing plant. After the beams and columns are installed on the construction site, the shock-absorbing energy-dissipating supports are connected to the frame beams and frame columns through bolt connections. The wall panels and frame beams are connected by bolts, the prefabricated floor slab rests on the beams, and the cast-in-place floor slab is poured on the prefabricated floor slab.

[0030] Take a three-story villa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com