Single-loop hydrofracturing in-situ stress measuring system

A hydraulic fracturing and stress measurement technology, applied in the field of measurement systems, can solve problems such as difficult handling, easy to get stuck in the hole, double-circuit unusable, etc., and achieve the effect of simplifying the test procedure, shortening the test time, and widening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

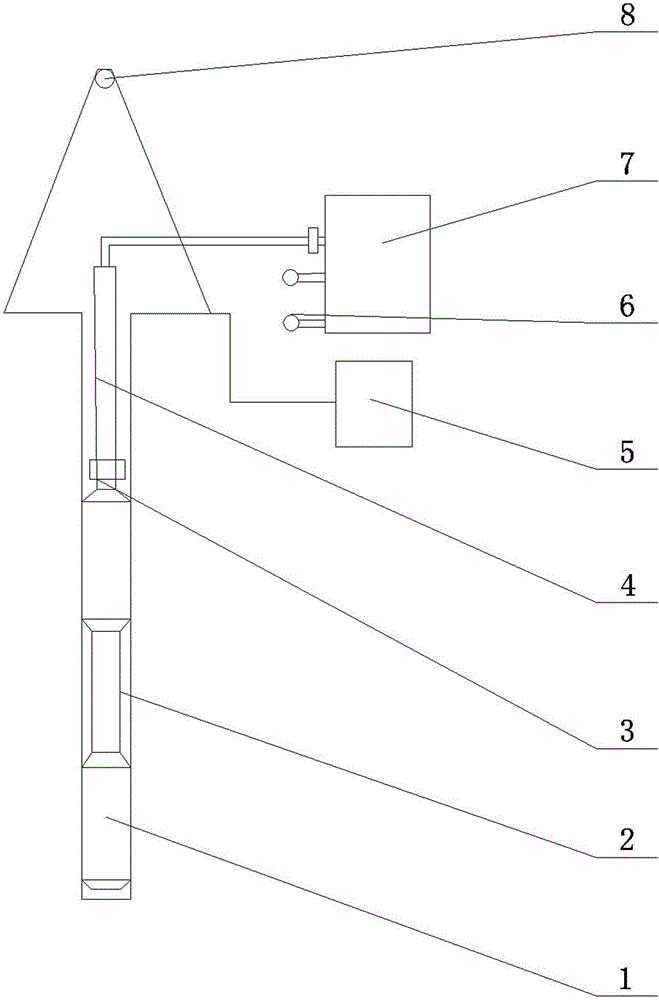

[0017] As shown in the figure, the present invention includes a high-pressure pump 7, a pressure sensor 9 is arranged on the side of the high-pressure pump 7, and a pressure recorder 5 is arranged on the side of the high-pressure pump 7 corresponding to the pressure sensor 9; A drill hole is provided on the side, the drill hole is arranged under the derrick 8, a drill pipe 4 is arranged in the drill hole, the high-pressure pump 7 is connected with the drill pipe 4, the lower end of the drill pipe 4 is connected with the packer 1, and the drill pipe 4 is connected with the A transfer switch 3 is arranged between the packers 1 , and a fracturing section 2 is arranged in the middle of the packer 1 .

[0018] The drill rod 4 is made of stainless steel; the stainless steel drill rod is durable and not easily corroded and rusted by water.

[0019] The single-circuit hydraulic fracturing test system must meet the three key links of setting, fracturing and unsealing in the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com