Construction method of impact prevention and shock absorption supporting structure of ingate

A support structure and construction method technology, applied in the direction of earthwork drilling, shaft equipment, mining equipment, etc., can solve problems such as deterioration of stress state, superposition of concentrated stress, and large-scale spalling of reinforced concrete, so as to improve toughness and impact resistance ability, good energy absorption and crack resistance, and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention discloses a construction method of a horse head door anti-shock shock-absorbing support structure. In order to make the advantages and technical solutions of the invention clearer and clearer, the invention will be further clearly and completely described below in conjunction with specific embodiments.

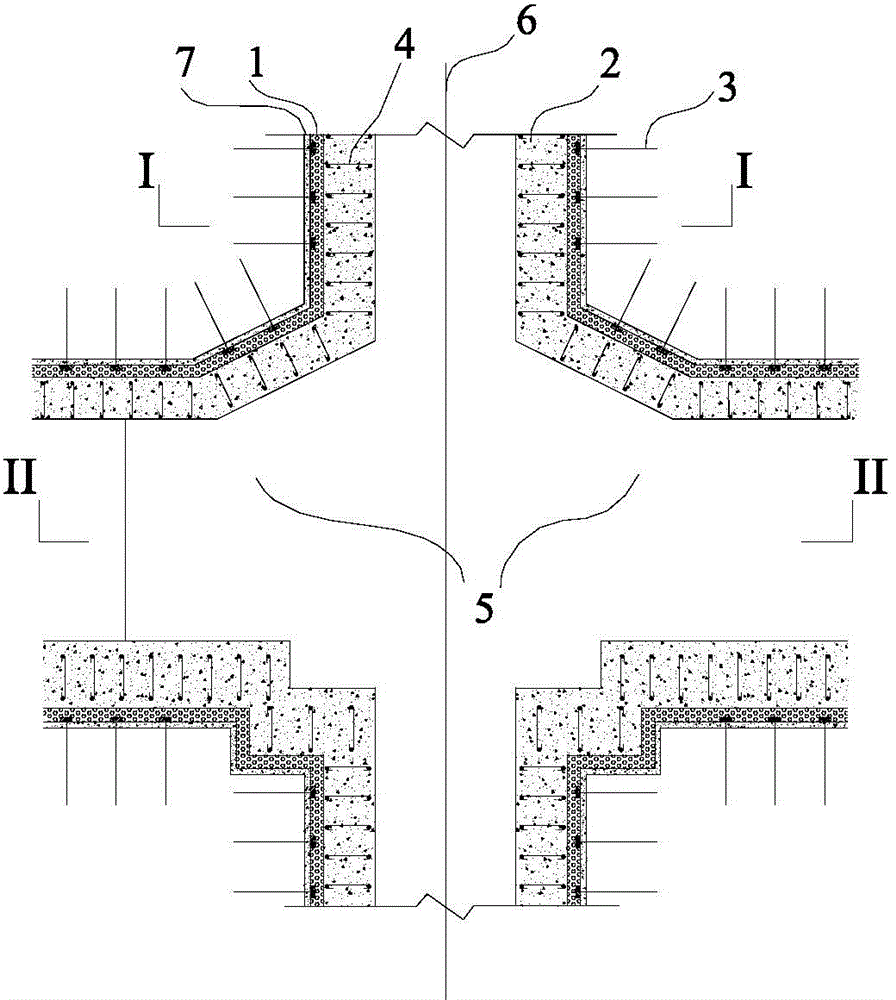

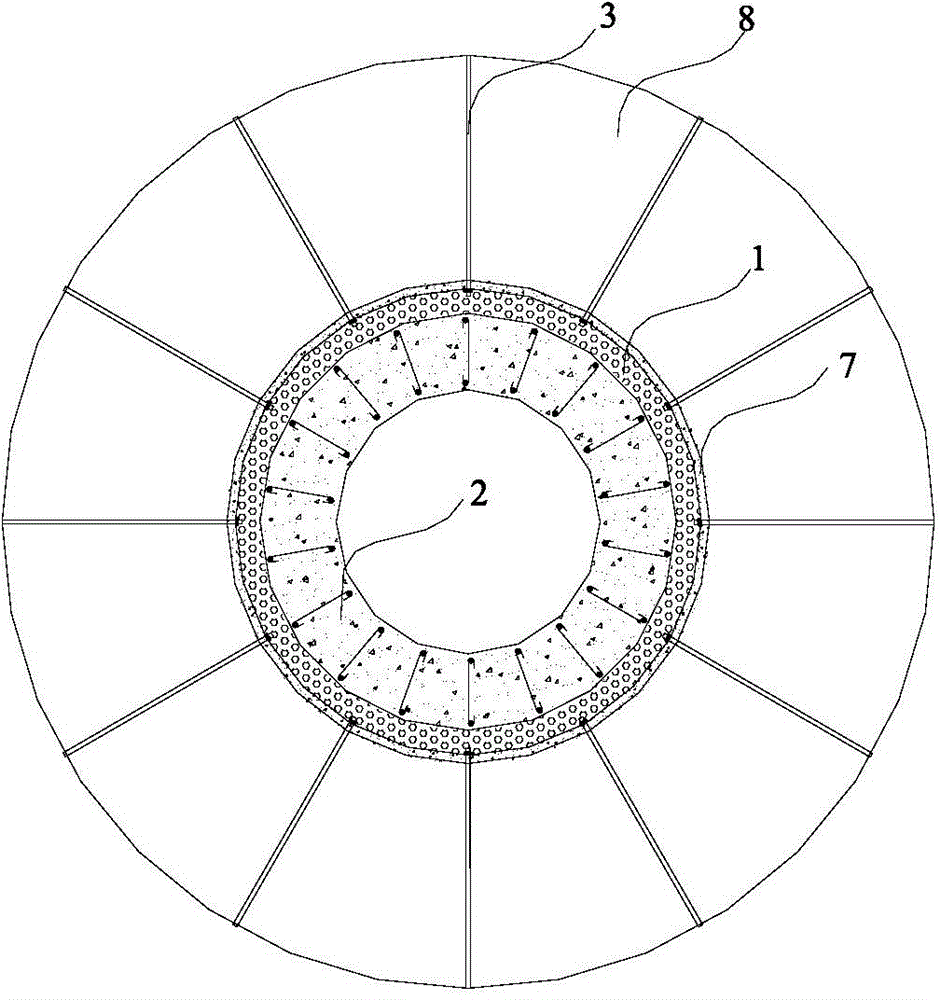

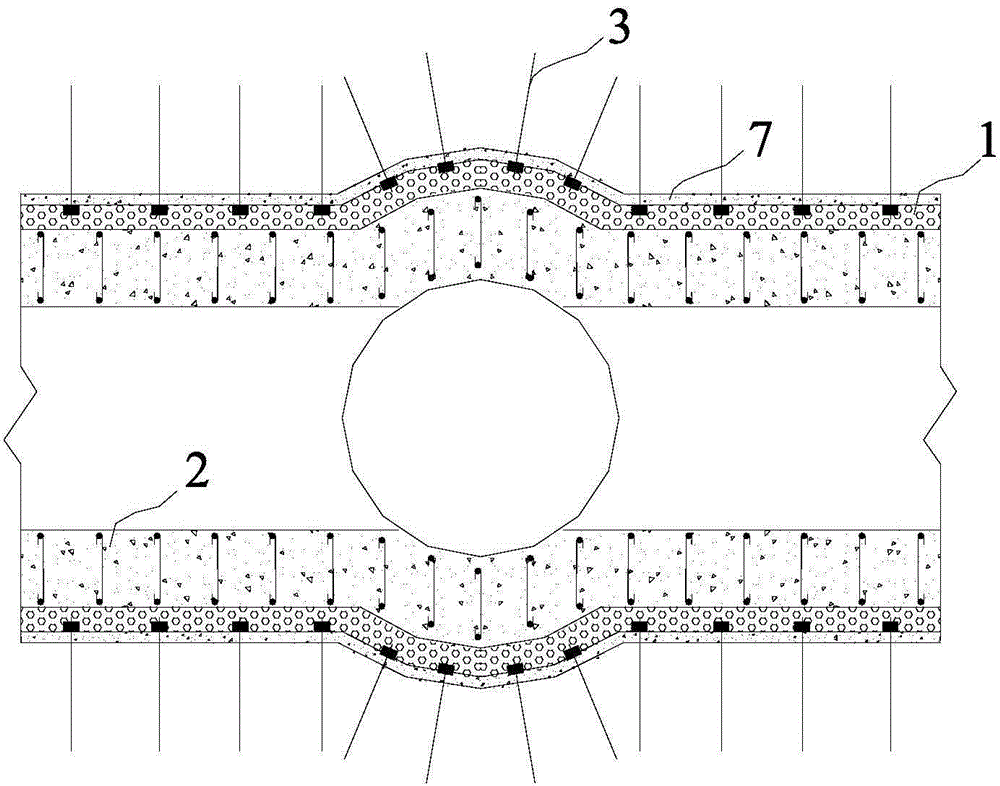

[0031] First, a kind of anti-shock and shock-absorbing support structure of horse head door of the present invention is described in detail, as figure 1 As shown, it includes high-toughness reinforced concrete grouting layer, composite foam metal cushion layer 1 and anchor cable grouting reinforcement layer 8, wherein the high-toughness reinforced concrete layer and anchor cable grouting reinforcement layer 8 are used as rigid structures, and the composite foam metal cushion layer 1 As a flexible structure, the combination of the three forms a "strong-weak-strong" Matoumen 5 support structure under the shaft 6, which can exert the collaborative deformation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com