Cabin-type anchoring device and construction method using fiber-reinforced composite materials

A technology of reinforced composite materials and composite materials, applied in the field of civil engineering, can solve the problems of unresolved technical problems of steel anchor anti-corrosion, self-heavy steel, and increased cost of rock and soil anchoring construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention is described in detail below with reference to accompanying drawing and embodiment:

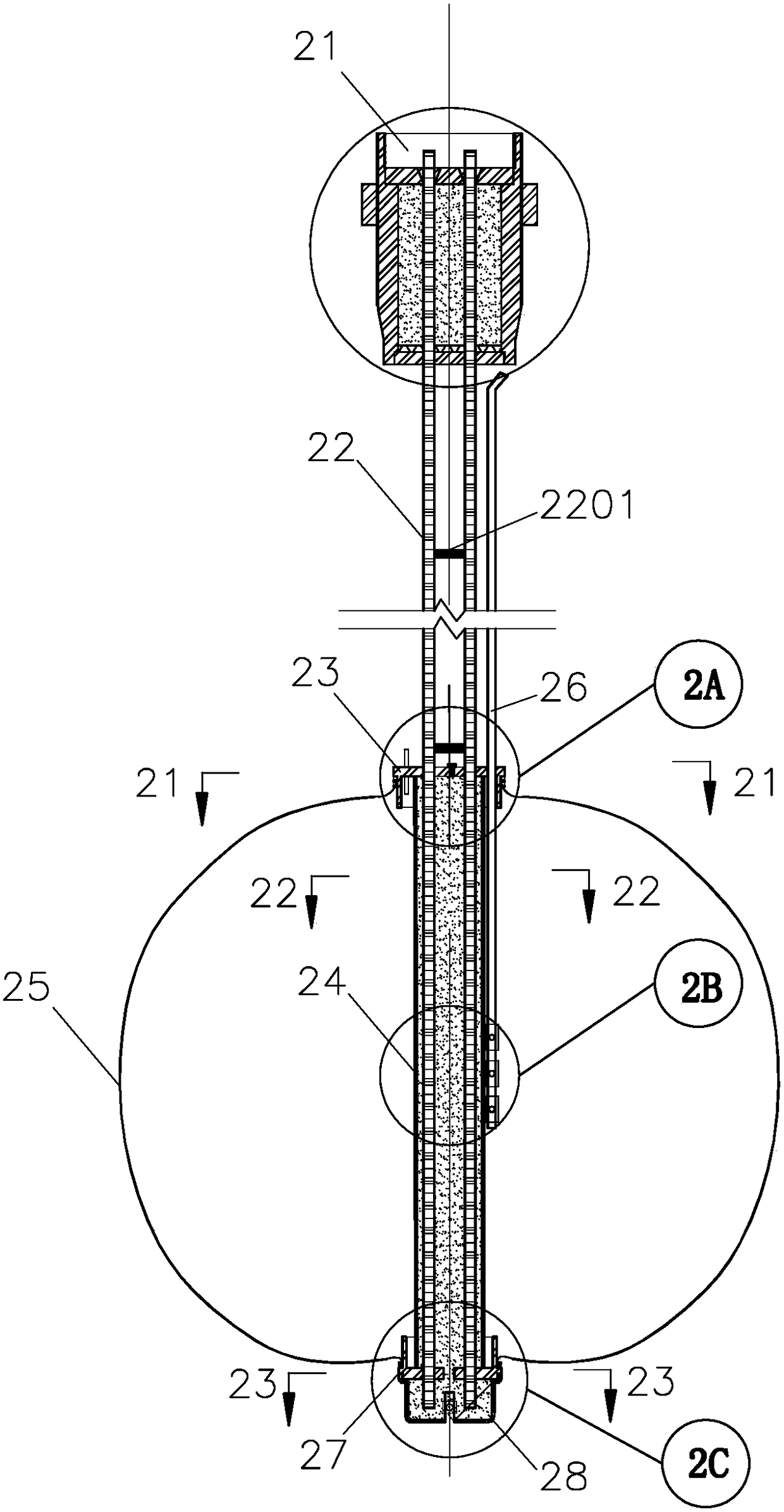

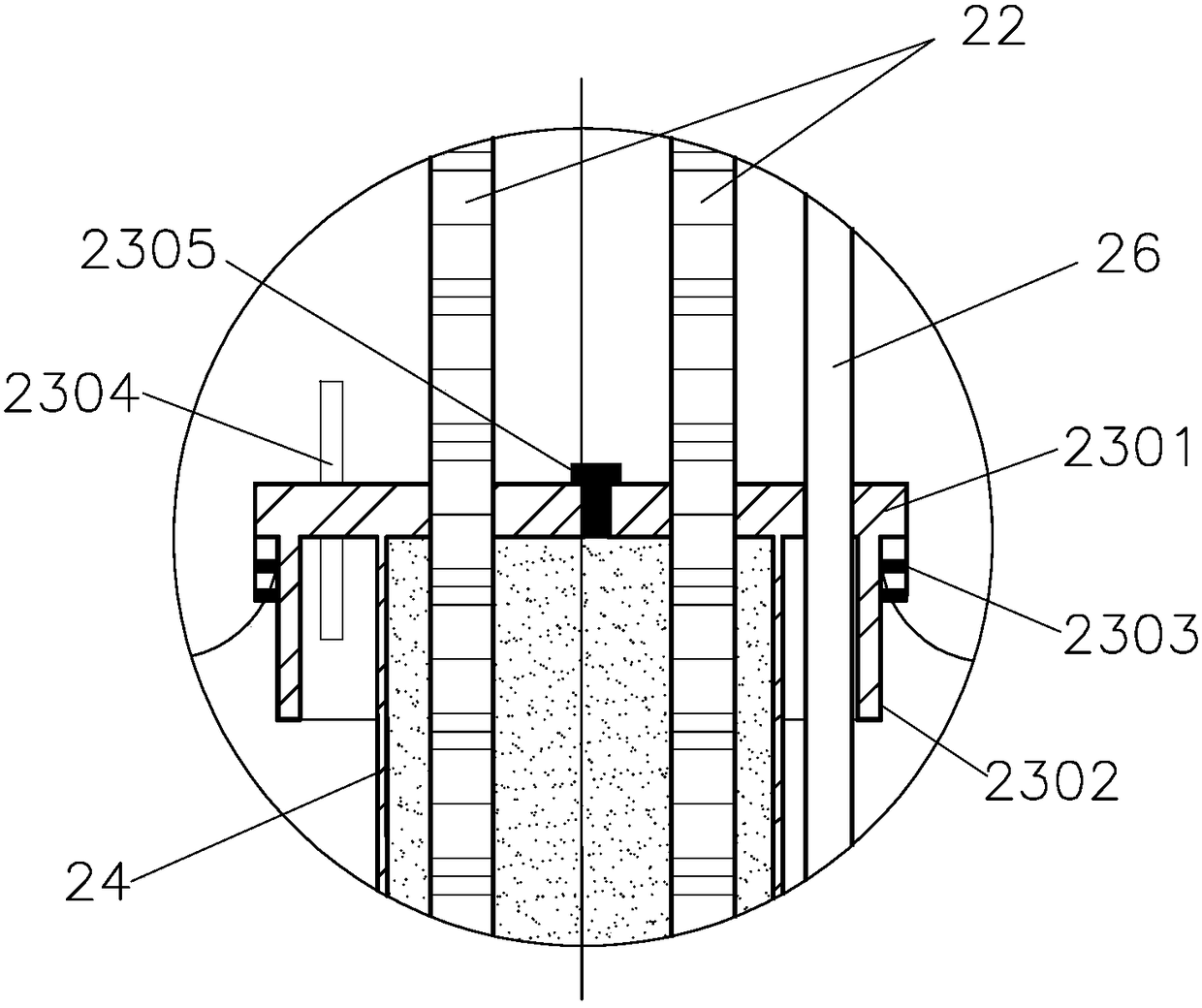

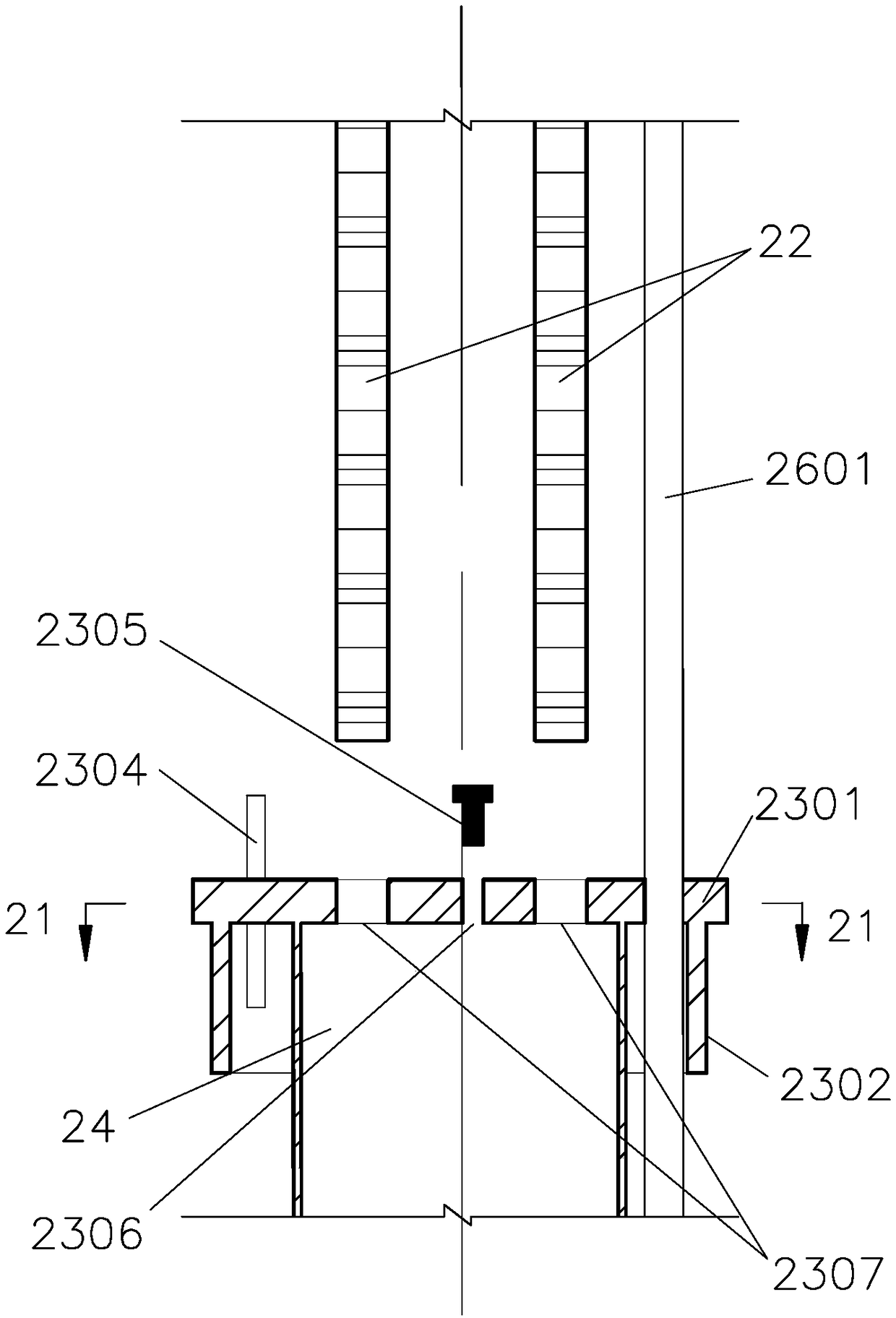

[0080] Such as Figure 1-12As shown, in Embodiment 1 of the present invention, a cabin-type anchoring device using fiber-reinforced composite materials includes a structural anchoring component 21, an upper positioning component 23, a bonding sleeve 24, a grouting pipe 26, a lower positioning component 27 and a grouting Guide cap 28. One end of 4 BFRP basalt fiber reinforced composite tendons 22 of equal section is fixed on the structural anchor assembly 21, and the other end passes through the upper positioning assembly 23 and the lower positioning assembly 27 respectively, and passes through The hydraulic one-way grouting valve 2802 fixed on the grouting guide cap 28 injects the cement slurry, cement mortar or synthetic resin in the grouting guide cap 28 and the bonding sleeve 24 and is bonded and fixed on the grouting guide cap 28. Inside the bonding sleeve 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com